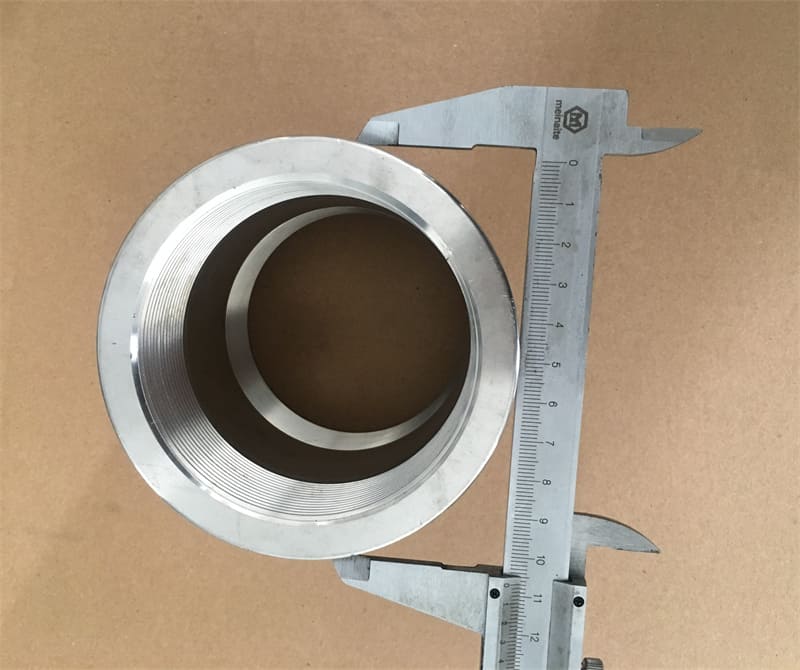

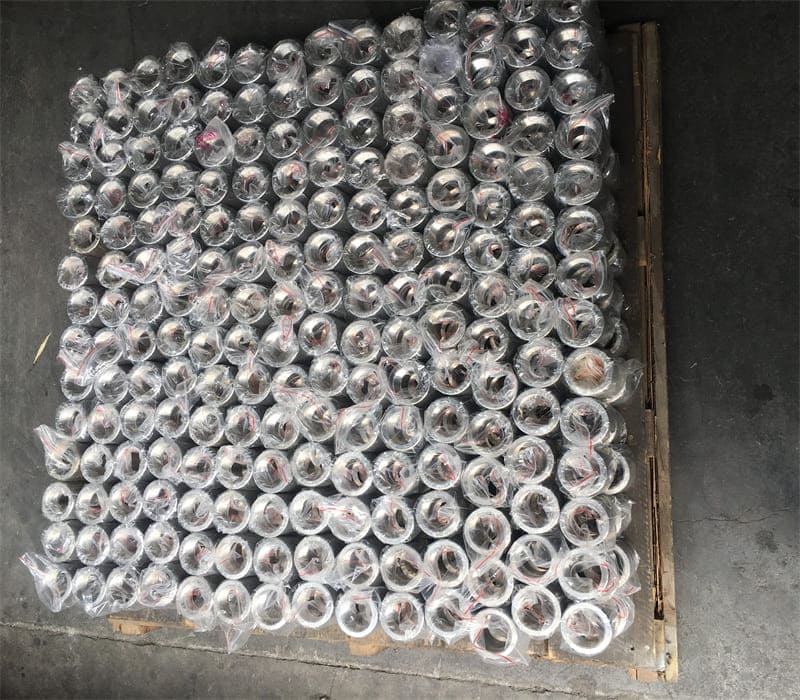

Threaded Elbow Class 3000 Forged Fittings

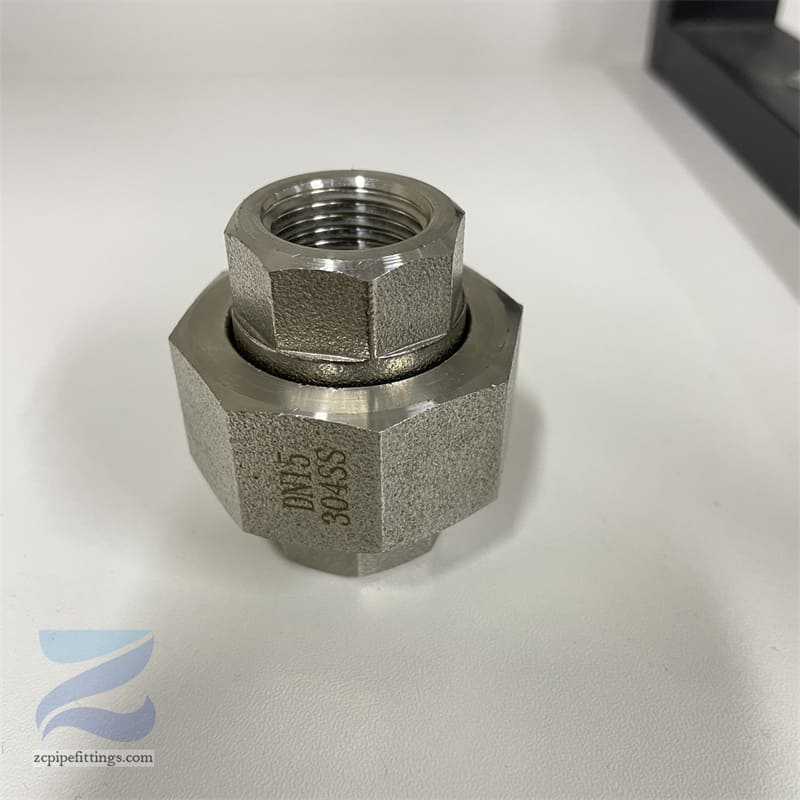

Threaded elbow used thread connection to connect with the pipes.Pipe elbows have three types:THD (threaded),SW (socket weld),BW (butt welded).These elbows used different connections to connect with the pipes in piping system.Class 3000 forged fittings are the most used high pressure fittings.

A pipe Threaded Elbow is actually a fitting that is being installed in between the two lengths of tube or a pipe to allow in changing the direction of a flow. The change in the direction is done generally in the 45°or 90°route. Forged Threaded Pipe Fittings Elbow also provides an eternal welded connection for essential applications.Class 3000 fittings is the mostly used fittings in many environments.

Threaded fittings are mainly used with small diameter pipes.Threaded fittings make the connection easy to operate,and also convenient for dismantle,based on this ,threaded fittings could save lots of cost for connecting pipes.

Types:

90 degree elbow: These elbows can change the direction of the pipe by 90 degrees.

45 degree elbow: These Threaded Elbows make 45°changes of direction in the run of the pipe.

Shape:

Straight elbow: The diameter of both ends of these elbows is the same.

Reducing elbow: A reducing elbow is a type of fitting which is used to join two pieces of pipe of different sizes.

Advantages:

- Easy to install.

- Firm and durable.

- Corrosion resistance.

Application:

Forged threaded elbows are very common in chemical, oil refining, petrochemical and other industries, and are also used in some other industries.

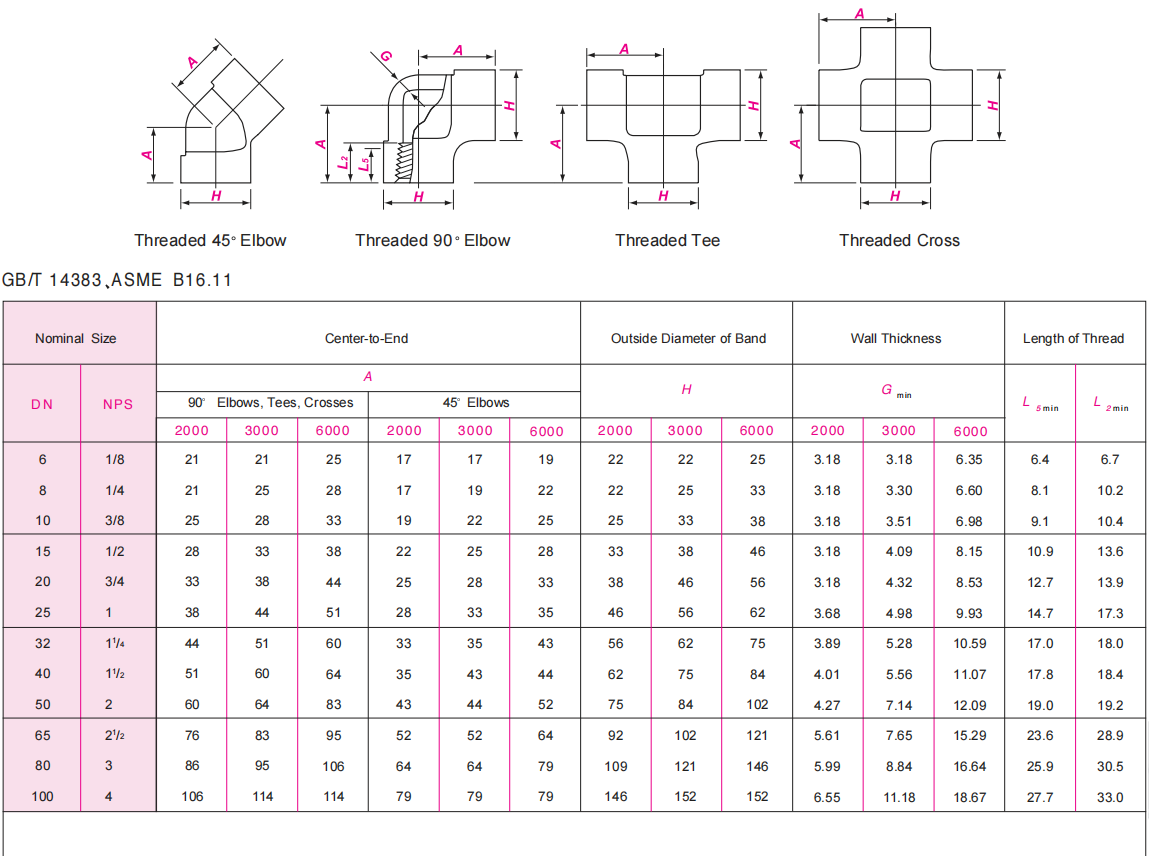

SPECIFICATION

| Shape | Elbow |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

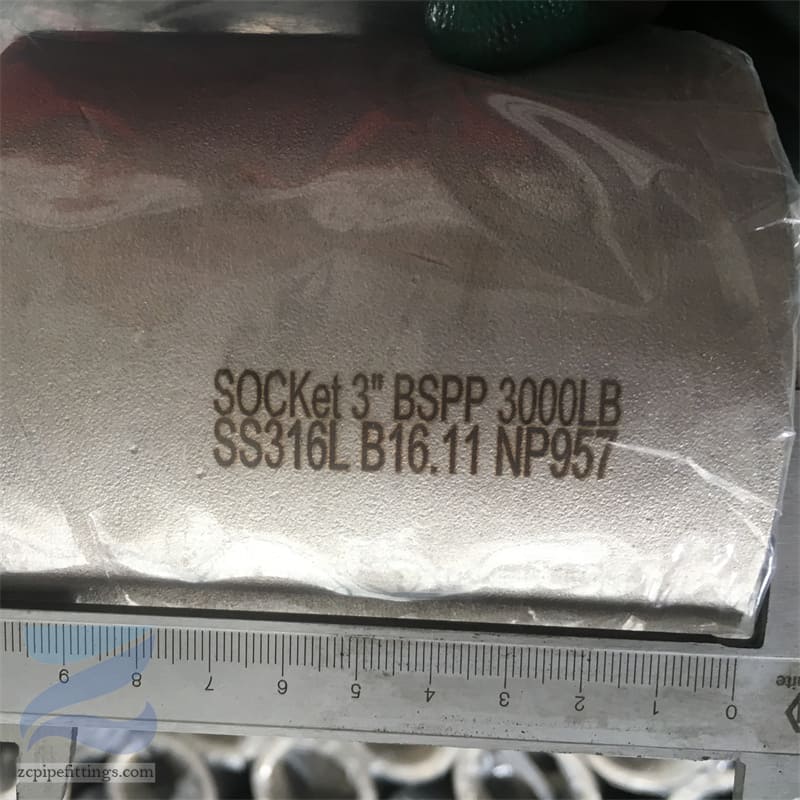

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |