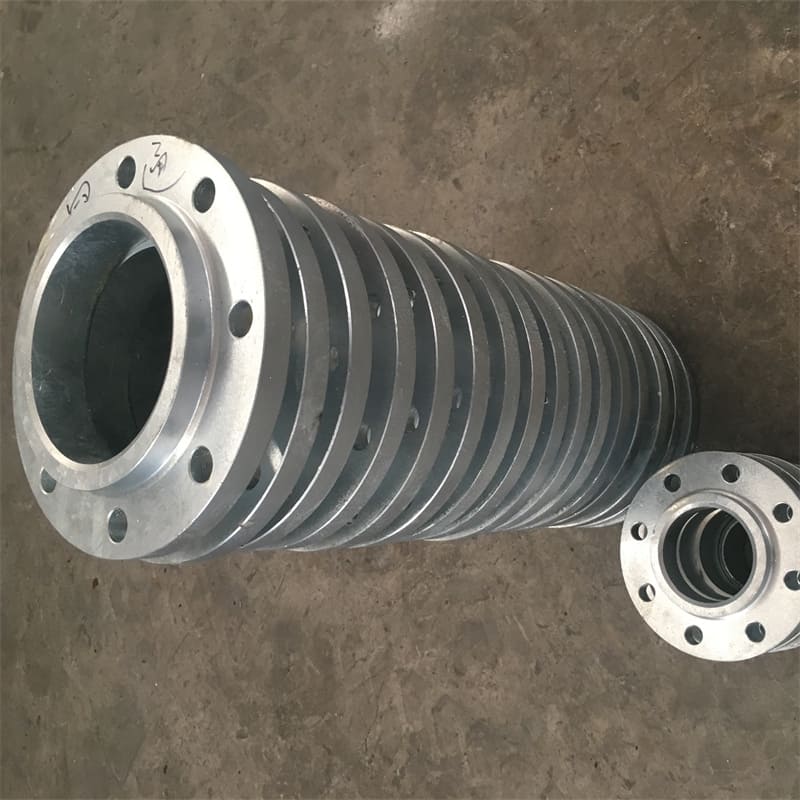

SW Flange Application Stainless Steel Flange

SW flange can be used in many applications in piping systems.SW Flanges are forged flanges.Socket weld flange has many classes:150LB, 300LB, 600LB, 900LB, 1500LB, 2500LB.Stainless steel flanges have better functions than other flanges which made from carbon steel or alloy steel.

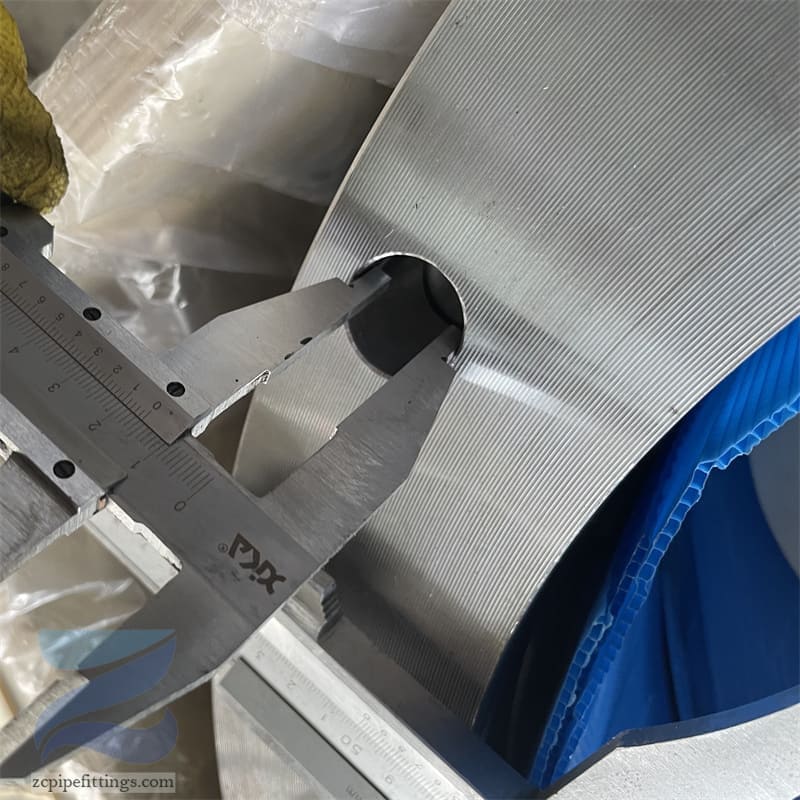

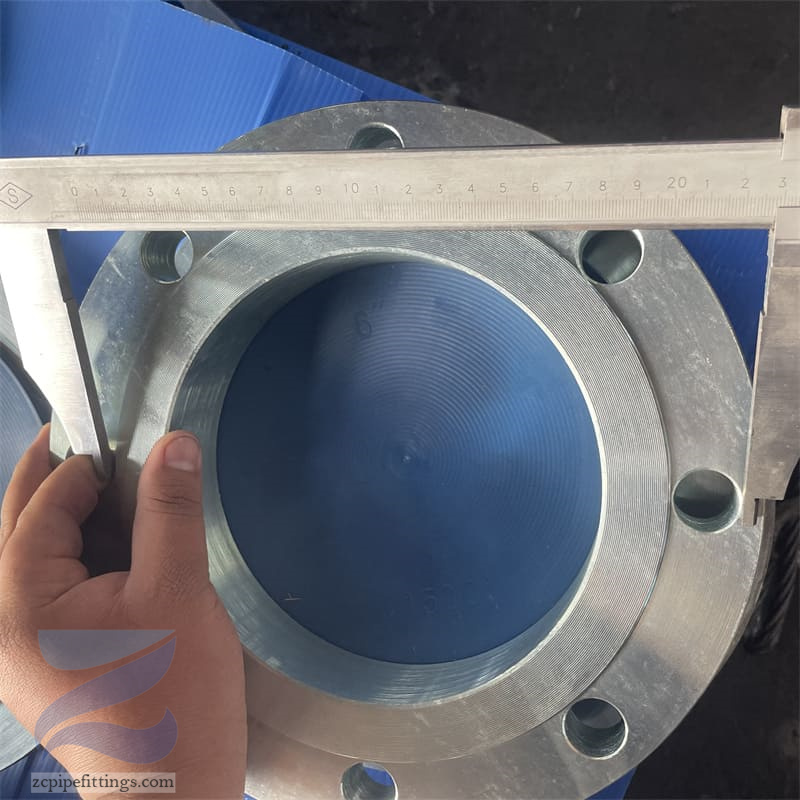

Socket weld flange simplified as SW flange, it has a recessed area (like a shoulder) in the flange bore, this shoulder serves as a guide to set the depth of the pipe that inserted to the flange. Socket welding flange initially designed for high pressure small diameters piping system.

Face:

Raised face, Flat face, RTJ facing.

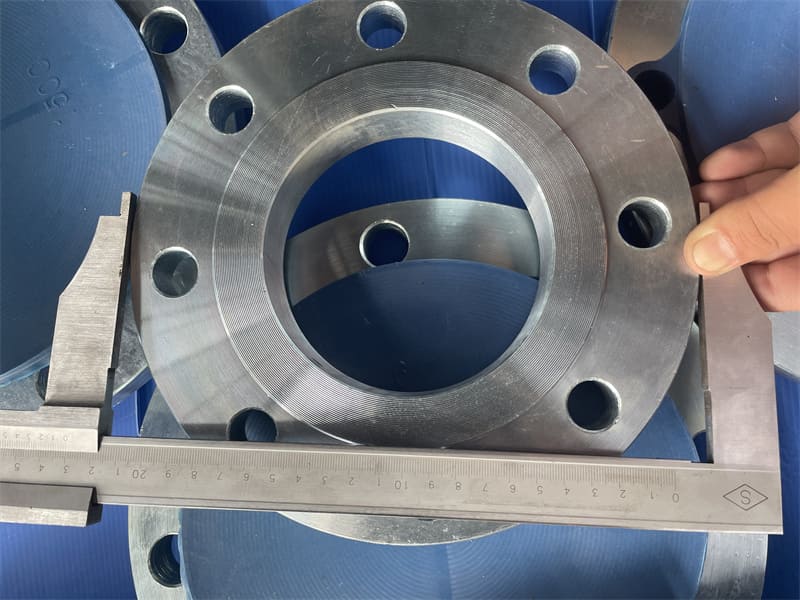

These pipe flanges are attached by inserting the pipe into the socket end and applying fillet weld around the top. This allows for a smooth bore and better flow of the fluid or gas inside of the pipe. The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe.

Advantages:

- Socket weld flange could replace threaded flange, to minimize the risky of leakage.

- No need to beveling before welding.

- Welding work outside of the pipe, will not penetrate the pipe bore.

- It is recommended for applications where internal welding operations are particularly difficult.

- Better fatigue life.

Disadvantages:

- Clearance must be left. Cracks between pipes and flanges can cause corrosion problems, mainly in stainless steel piping systems.

- In some processes this flange is also not allowed.

Applications:

An assembly with limited space may be an instance in which a socket weld is selected, provided the pressure class is comparatively low and the fluid is not corrosive or for extremely high temperature service.

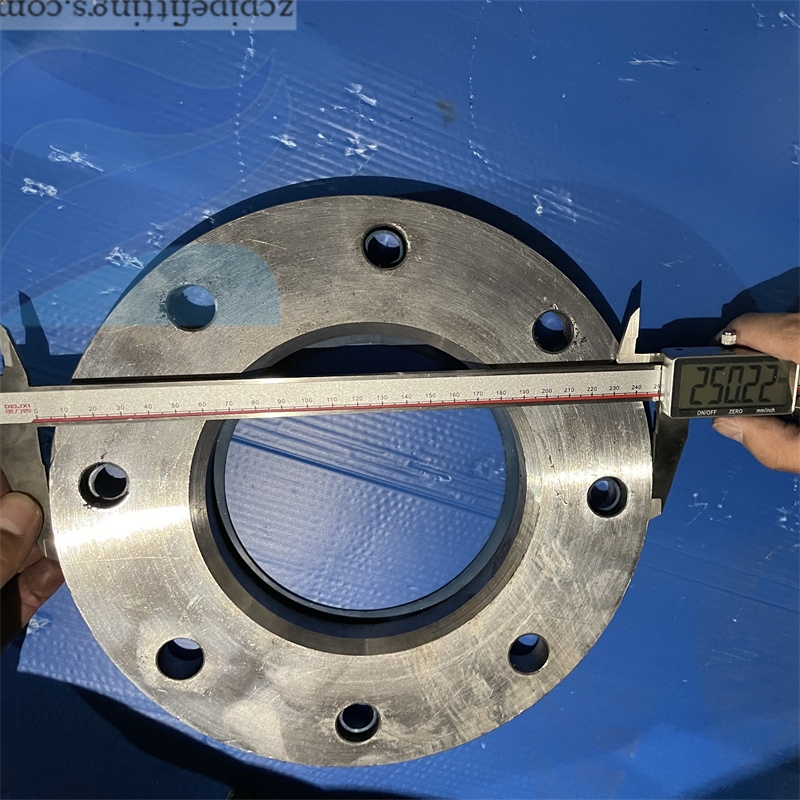

SPECIFICATION

| Shape | Socket Weld Flange (SW) |

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

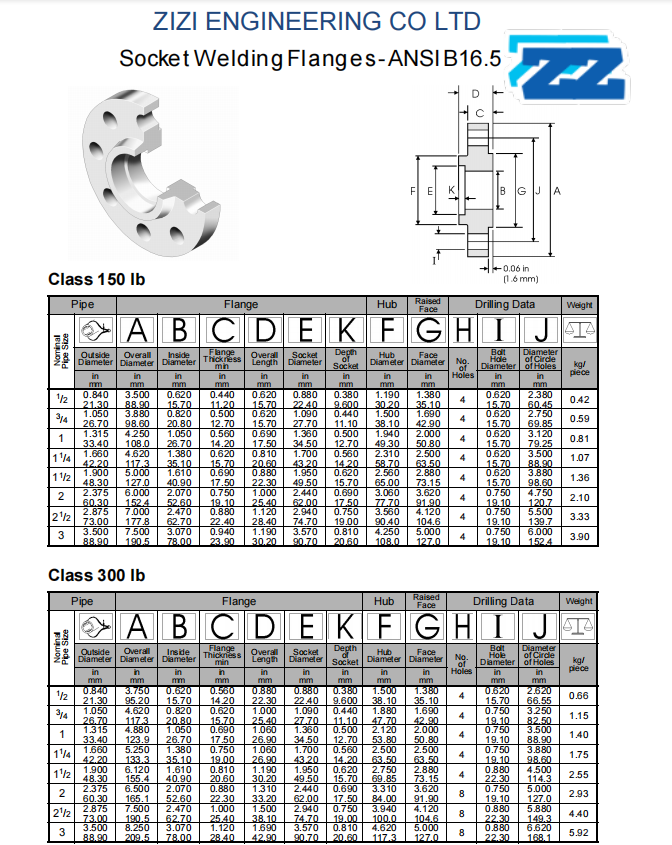

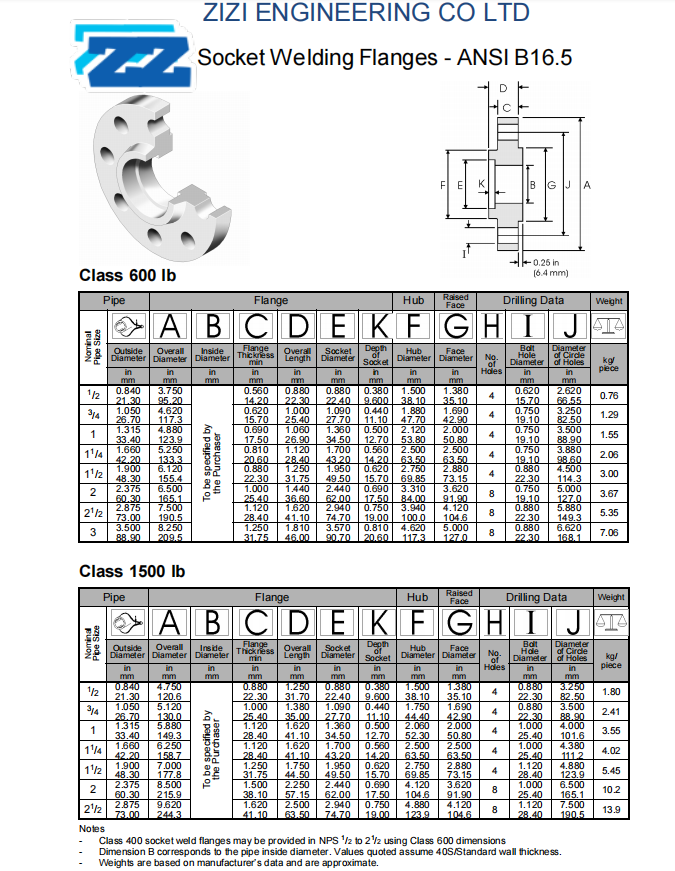

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |