Steel Pipe Fittings 90 Degree Elbow

Threaded elbow can reduce pipeline stress and pressure drop reduce pipeline stress, reduce pipeline pressure drop, and reduce pulsating power of fluid to pipeline.

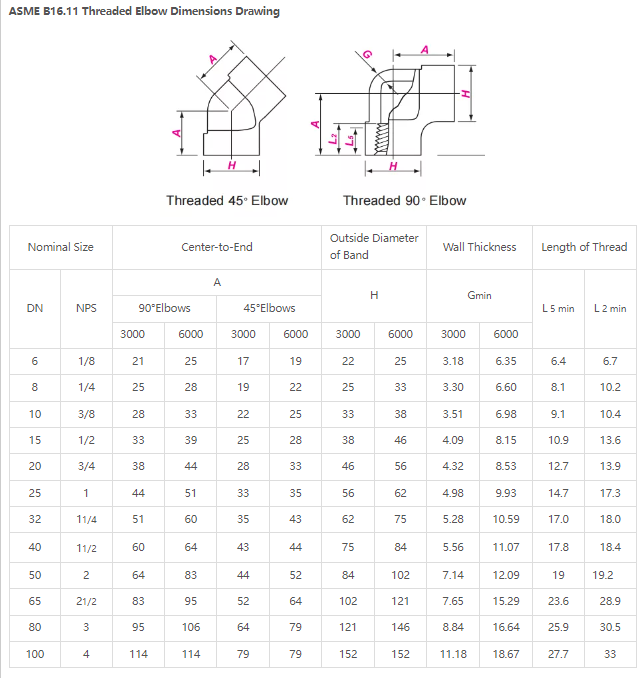

A pipe Threaded Elbow is actually a fitting that is being installed in between the two lengths of tube or a pipe to allow in changing the direction of a flow. The change in the direction is done generally in the 45°or 90°route. Forged Threaded Pipe Fittings Elbow also provides an eternal welded connection for essential applications.

Types:

90 degree elbow: These elbows can change the direction of the pipe by 90 degrees.

45 degree elbow: These Threaded Elbows make 45°changes of direction in the run of the pipe.

Shape:

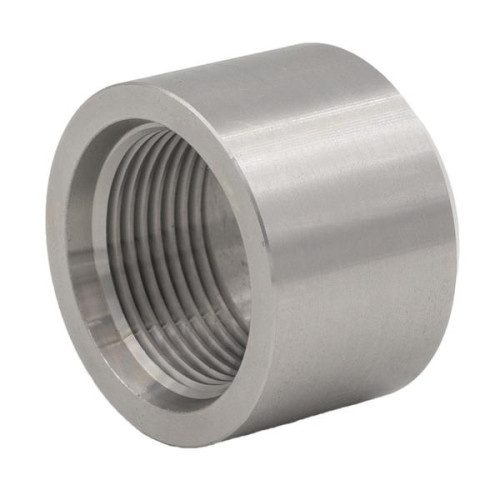

Straight elbow: The diameter of both ends of these elbows is the same.

Reducing elbow: A reducing elbow is a type of fitting which is used to join two pieces of pipe of different sizes.

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

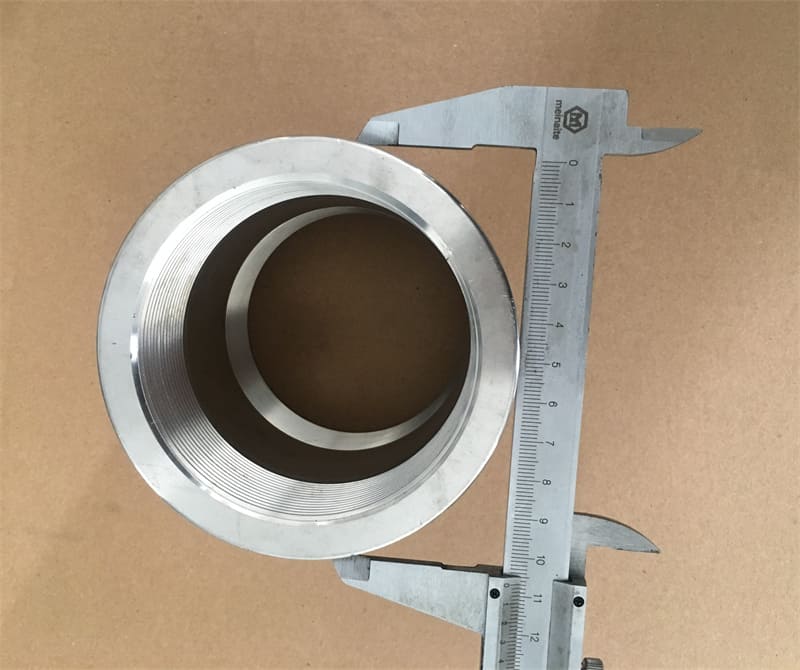

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Application:

Water and oil in chemical

Petrochemical

Shipbuilding

Waste incineration

Semiconductor industry