Stainless Steel A403 WP316316L Pipe Fitting Formula Tee

These Stainless Steel Pipe Fittings are best known for their heat resistance, creep strength and tensile strength. Machined and fabricated to meet your diverse piping requirements, these pipes fittings exhibit excellent corrosion resistance in a wide range of atmospheric environments.

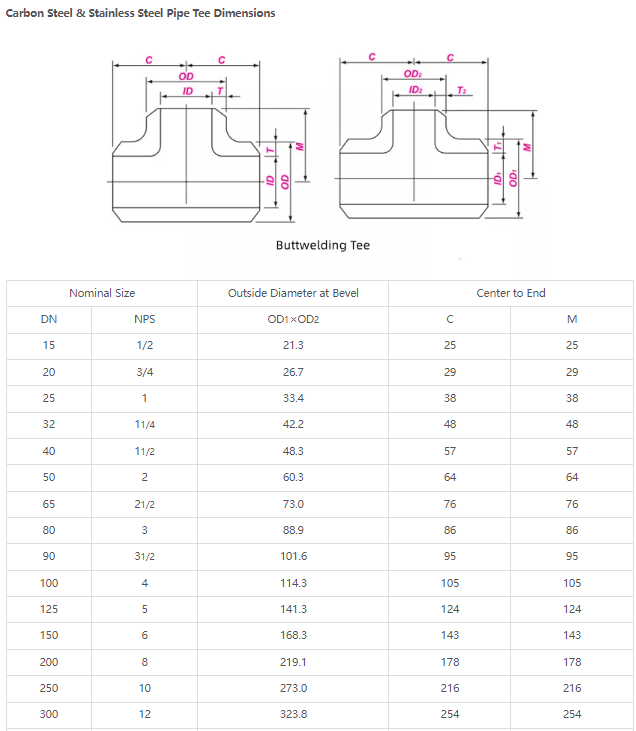

The ASME/ANSI B16.9 specification covers the dimensions and the tolerances of carbon, alloy and stainless-steel butt weld fittings.

Butt Weld Fittings are manufacture by seamless or welded pipe. For pipe fittings manufacturers, the forming process of welded pipe and seamless pipe is basically same. Butt welded fittings can be divided into carbon steel butt welded fittings and stainless-steel butt-welded fittings.

These Stainless Steel Pipe Fittings are best known for their heat resistance, creep strength and tensile strength. Machined and fabricated to meet your diverse piping requirements, these pipes fittings exhibit excellent corrosion resistance in a wide range of atmospheric environments.

| Butt Welding Fittings Specification | |

| Shape | Elbow, Tee, Cross, Bend, Reducer, Cap, Stub End |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

An equal tee, otherwise called straight tee, means the branch diameter of this tee is same with the main pipe (Run pipe) diameter of this tee.

A pipe tee is defined “equal” when the bore size at the run and branch sides have the same diameter. An equal tee is, therefore, used to connect two pipes of the same nominal diameter.

Stainless Steel Pipe Fitting Formula Tee drawing and dimensions