Stainless Steel A182 Swage Nipple Dimensions

A swage nipple is something similar to that of a reducer but it is used to join the butt welded pipe with a socket welded or screwed pipe.Like the reducer,swage nipple is also available with two variations:concentric swage nipple and eccentric swage nipple.The swage nipple generally adopts the MSS SP-95 or the BS3799 Standard.

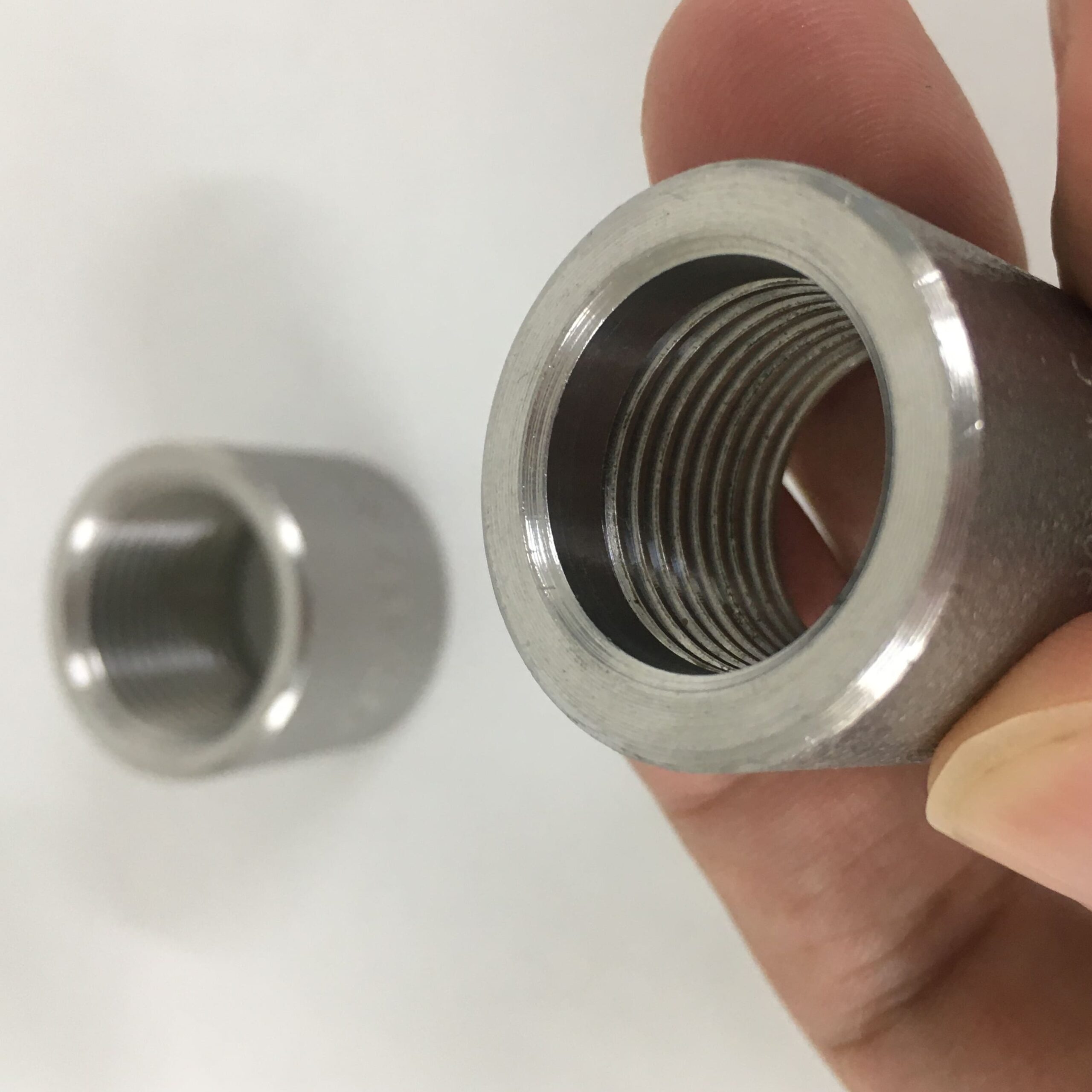

Description of Swage Nipple

A swage nipple is something similar to that of a reducer but it is used to join the butt welded pipe with a socket welded or screwed pipe.Like the reducer,swage nipple is also available with two variations:concentric swage nipple and eccentric swage nipple.The swage nipple generally adopts the MSS SP-95 or the BS3799 Standard.

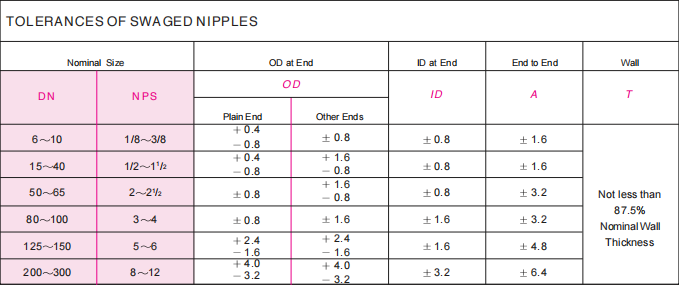

Dimensions and Tolerance of Stainless Steel A182 Swage Nipple

Material

These Stainless Steel A182 Swage Nipple are best known for their heat resistance, creep strength and tensile strength. Machined and fabricated to meet your diverse piping requirements, these pipes fittings exhibit excellent corrosion resistance in a wide range of atmospheric environments.

The specification of ASTM A182 Stainless Steel Forged Pipe Fittings includes forged fittings, stainless steel, rolled alloy, forged alloy, pipe flanges as well as high-temperature service. Later then forgings and hot working, it would be cooled down to a certain temperature before heat treatment.

Composition of Stainless Steel A182 Swage Nipple

Table 1. Composition ranges for 316 grade of stainless steels.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | Min | – | – | – | 0 | – | 16.0 | 2.00 | 10.0 | – |

| Max | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316L | Min | – | – | – | – | – | 16.0 | 2.00 | 10.0 | – |

| Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

| 316H | Min | 0.04 | 0.04 | 0 | – | – | 16.0 | 2.00 | 10.0 | – |

| max | 0.10 | 0.10 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | – |

Mechanical Properties of Stainless Steel A182 Swage Nipple

Table 2. Mechanical properties of 316 grade stainless steels.

| Grade | Tensile Str (MPa) min |

Yield Str 0.2% Proof (MPa) min |

Elong (% in 50mm) min |

Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

| 316H | 515 | 205 | 40 | 95 | 217 |