Stainless Steel A182 F316 Weld Neck Flange

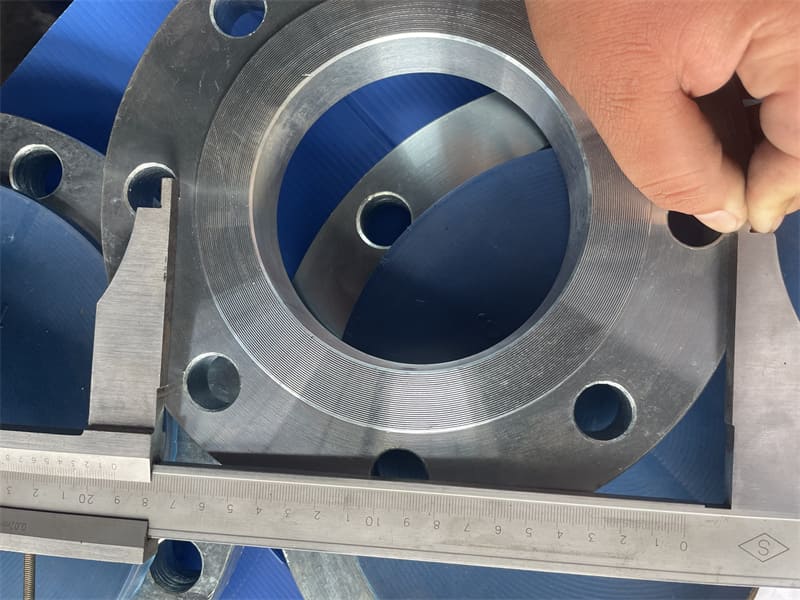

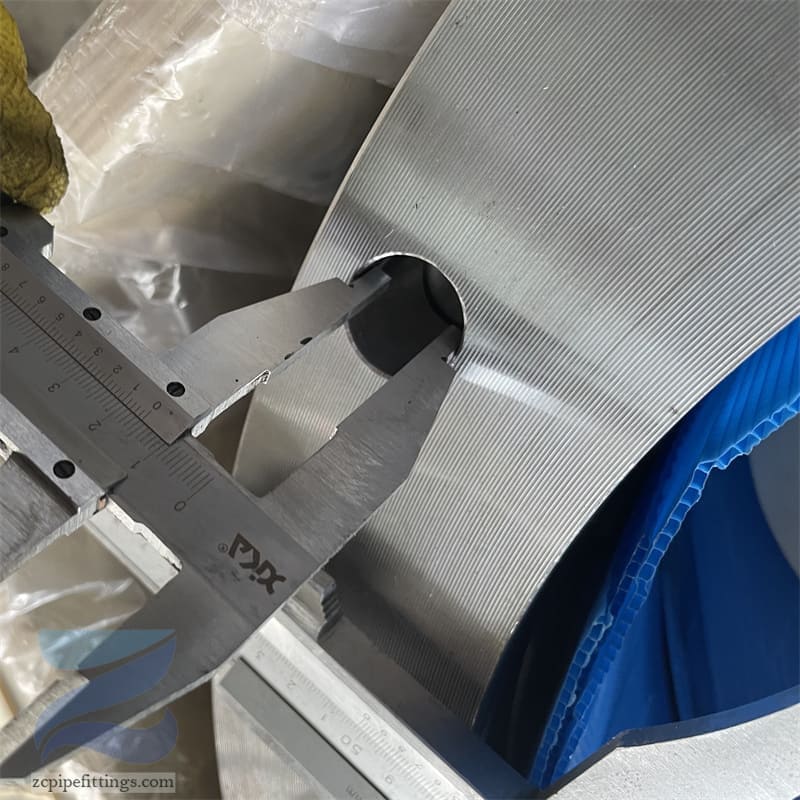

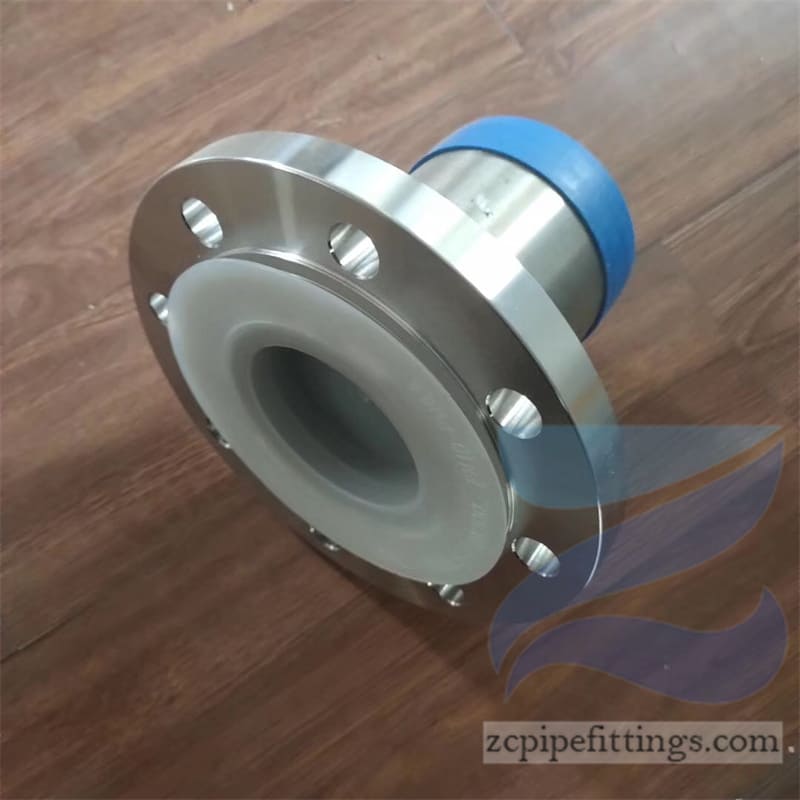

Stainless steel weld neck flange is a part widely used in pipeline engineering. The diameter and wall thickness of the pipe at the interface end are the same as the pipe to be welded, and the connection of the pipe is realized by welding.

Stainless steel weld neck flange is a kind of parts used in pairs, mainly for the connection of pipelines, by welding the flange and the pipe butt, to ensure the connection of the firmness and tightness,Stainless steel weld neck flange is widely used in petroleum, chemical, natural gas, electric power, metallurgy, shipbuilding, and other industries of high pressure, high temperature, corrosive pipeline system. Especially in the need for high sealing, high pressure resistance occasions.

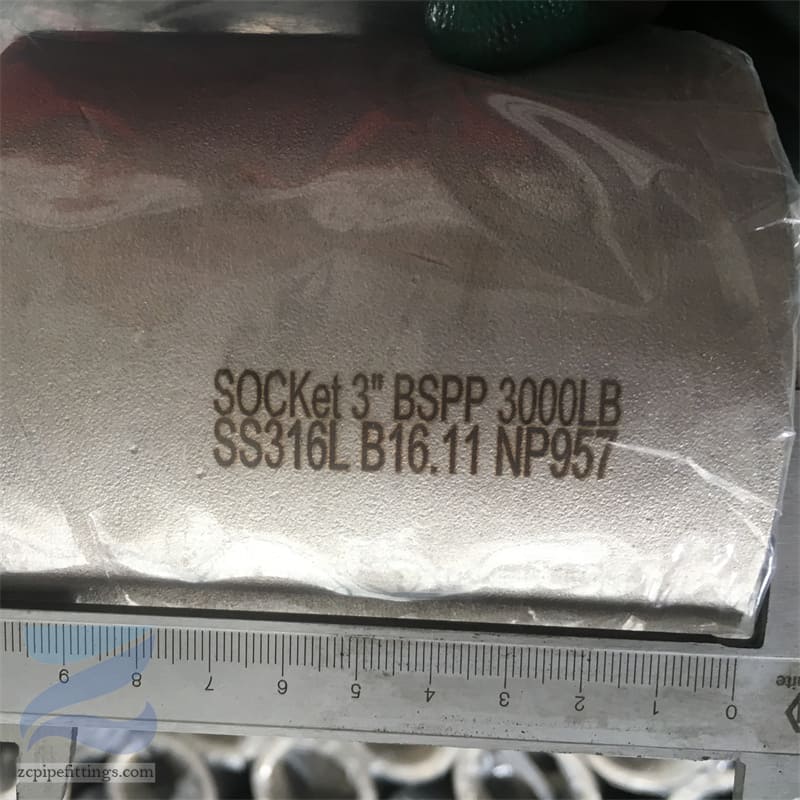

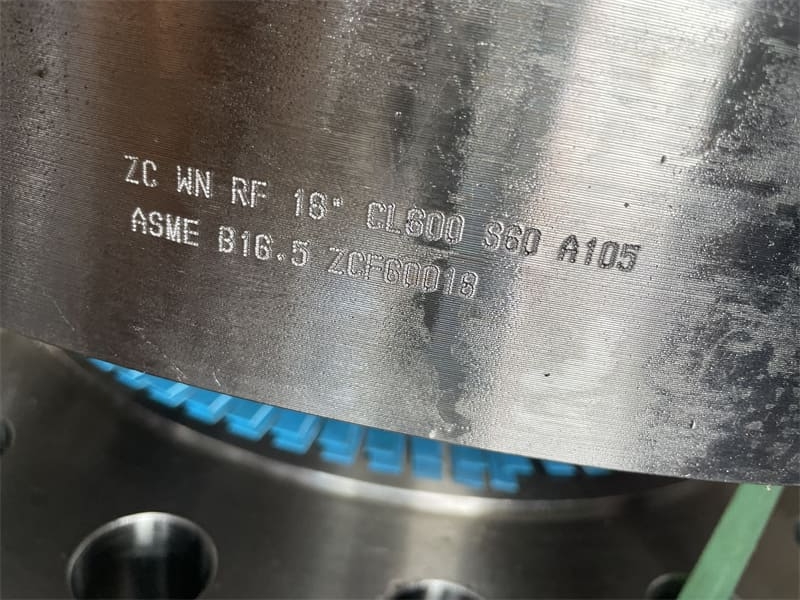

Stainless Steel Weld Neck Flanges Specifications

| Standards | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Size | 1/2″ NB TO 60″ NB |

| Material | ASTM A182 |

| Class | 150#, 300#, 400#, 600#, 900#, 1500# & 2500#. |

| Grade | ASTM A182 F304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L etc. |

A182 F316 Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

| ASTM A182 F316 | MIN | 10.0 | 16.0 | 2.00 | ||||||

| MAX | 0.08 | 2.00 | 0.045 | 0.030 | 1.00 | 14.0 | 18.0 | 3.00 | 0.01 |

A182 F316 Mechanical Properties

| MATERIAL | ASTM A182 F316 |

| T.S (MPA) | 515 min |

| Y.S (MPA) | 205 min |

| EL % | 30 min |

| R/A % | 50 min |

Advantages of a stainless steel A182 F316 weld neck flange

High intensity and stiffness: The structural design of the weld neck flange makes it have high strength and stiffness, can withstand high internal pressure and external force, to ensure the stability and safety of the piping system.

Good sealing ability: Through the precise processing and welding process, the stainless steel weld neck flange can ensure the close connection with the pipeline, effectively prevent the medium leakage, and meet the requirements of high sealing.

High-temperature and low-temperature resistance: Stainless steel material has good thermal stability, can maintain its physical and chemical properties in high or low temperature environment, adapt to various extreme conditions.

Easy for installation and maintenance: The installation process of stainless steel weld neck flange is relatively simple, and easy to remove and reinstall, easy maintenance and overhaul of pipes. At the same time, its standardized design and manufacturing make it highly interchangeability, reducing the installation and maintenance costs.