Spectacle Blind Flange

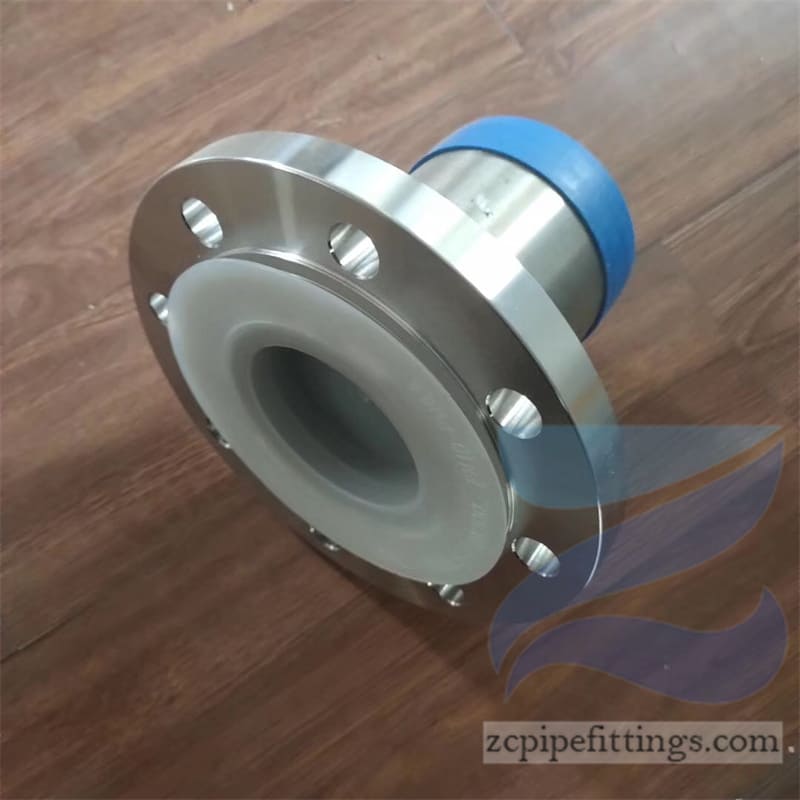

The spectacle blind flange is named because its shape resembles the number “8”. One end is a blind and the other end is an iron ring. However, the diameter of the throttling ring is the same as the diameter of the pipe and does not play a throttling role. This design makes the spectacle blind flange uniquely flexible and practical in the pipeline system.

The spectacle blind flange is named because its shape resembles the number “8”. One end is a blind and the other end is an iron ring. However, the diameter of the throttling ring is the same as the diameter of the pipe and does not play a throttling role. This design makes the spectacle blind flange uniquely flexible and practical in the pipeline system.

The spectacle blind flange is usually used on pipelines with larger diameters, especially at the flanges of pipelines where the process needs to be changed. It is often used in pipeline systems in petrochemical, electric power, metallurgy and other industries to ensure the safe, stable and efficient operation of the pipeline system.

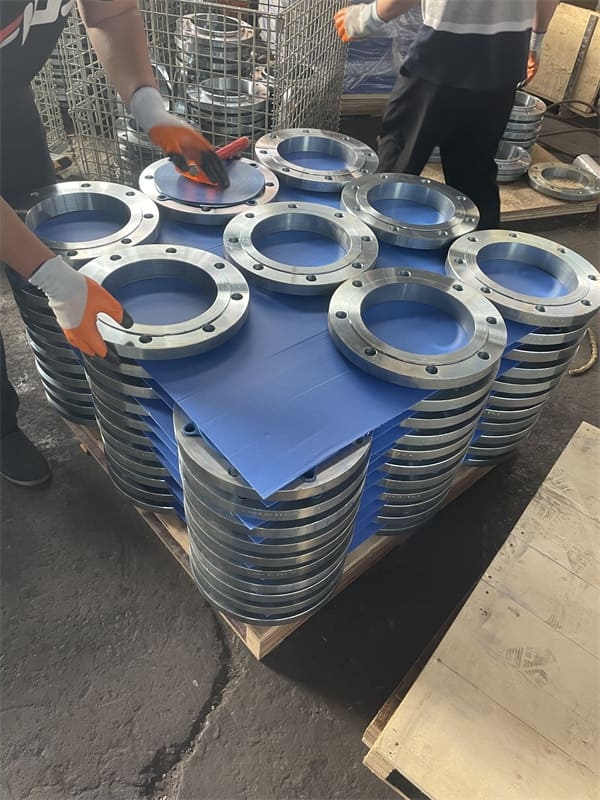

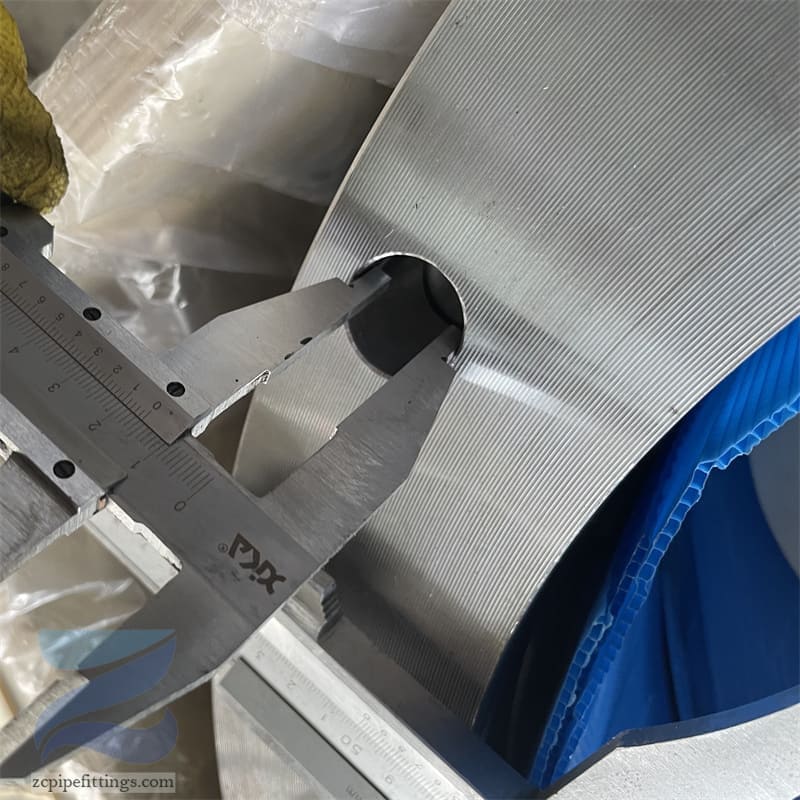

Specification of Spectacle Blind Flange

| Sealing Face | RF, FF, FTJ |

| Size Range | 1/2” – 48” / DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

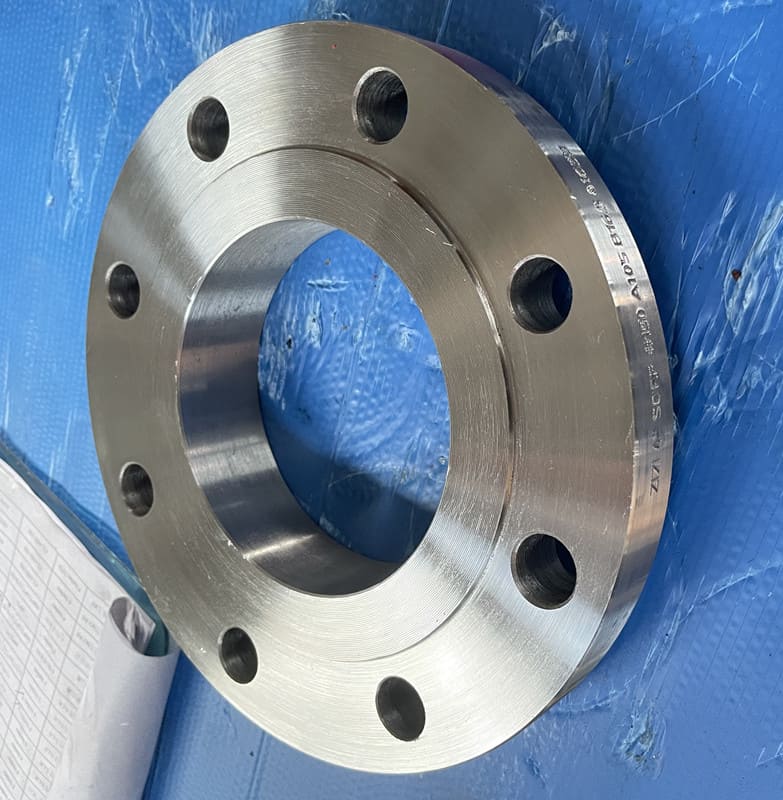

| Standard | ASME B16.48 ,ASME B16.5 |

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Functional use of Spectacle Blind Flange

Isolation and conduction

When a certain section of the pipeline system needs to be completely isolated, the Spectacle Blind Flange can be installed as a blind plate to partially block the pipeline. For example, when a certain device in the pipeline is being repaired, the spectacle Blind flange can be installed as a blind to prevent the medium in other pipelines from flowing into the pipeline section where the device is located, ensuring the safety of the maintenance.

When the pipeline needs to be conducted, the spectacle blind flange is rotated 180 degrees and installed so that the part with holes is connected to the pipeline, so that the normal flow of the pipeline can be restored. For example, when the production process is switched, if the spare pipeline needs to be put into use, it can be achieved by adjusting the state of the spectacle blind flange.

Pressure test

After the pipeline system is installed, a pressure test is required. The spectacle Blind flange can be used to close the end of the pipeline of the test section so that the medium (such as water or air, etc.) can be injected into the test section for pressure testing. By observing the pressure changes, the tightness and strength of the pipeline system can be detected.

Process switching

In some complex industrial production processes, there are multiple material flow directions or operation modes. The spectacle Blind flange can easily realize the switching between different processes. For example, in an oil refinery, the production processes of different oil products may have some shared pipelines. By adjusting spectacle Blind flange, it is possible to switch between the production of different oil products.