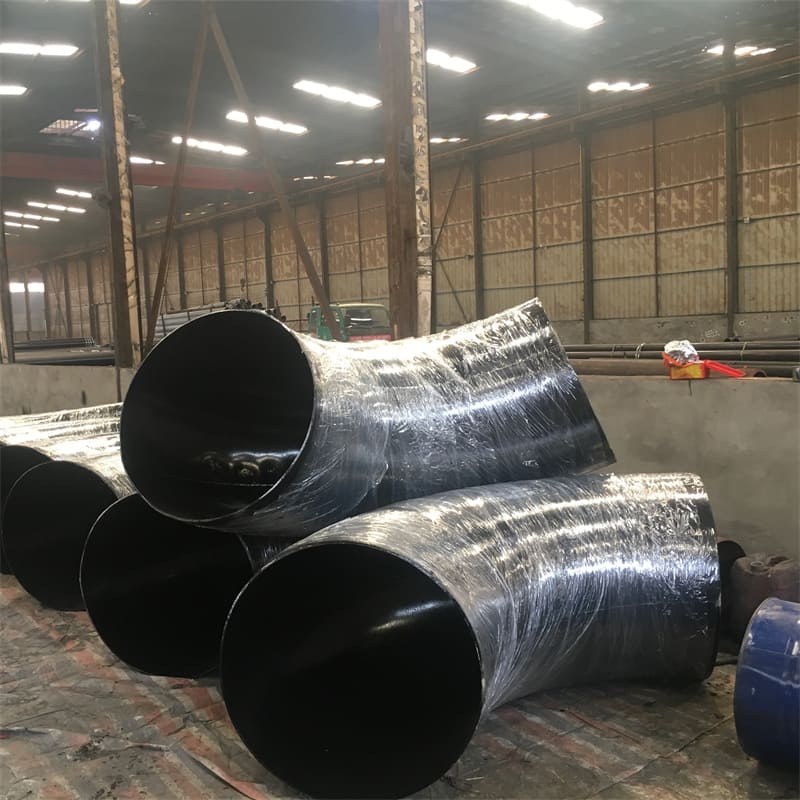

S31803 90 DEG ELBOW LR

S31803 90 degree elbow is a kind of stainless steel with two-phase structure of ferrite and austenite. It combines the high strength of ferritic stainless steel with the good toughness and corrosion resistance of austenitic stainless steel.

S31803 90 degree elbow is a kind of stainless steel with two-phase structure of ferrite and austenite. It combines the high strength of ferritic stainless steel with the good toughness and corrosion resistance of austenitic stainless steel.

S31803Duplex stainless steel has excellent corrosion resistance and performs well in environments containing chloride ions (such as seawater, chemical media, etc.). For example, in the pipeline system in marine engineering, the use of duplex stainless steel elbows can effectively resist the corrosion of seawater and extend the service life of the pipeline system.

It also has good resistance to stress corrosion cracking, which is due to its unique two-phase structure that can inhibit the expansion of stress corrosion cracks.

The high strength and good toughness of duplex stainless steel elbows enable the elbows to withstand certain external forces such as bending, stretching and impact during installation and use. When the layout of the pipeline system is adjusted or it is impacted by fluid, duplex stainless steel elbows are not easy to break or deform.

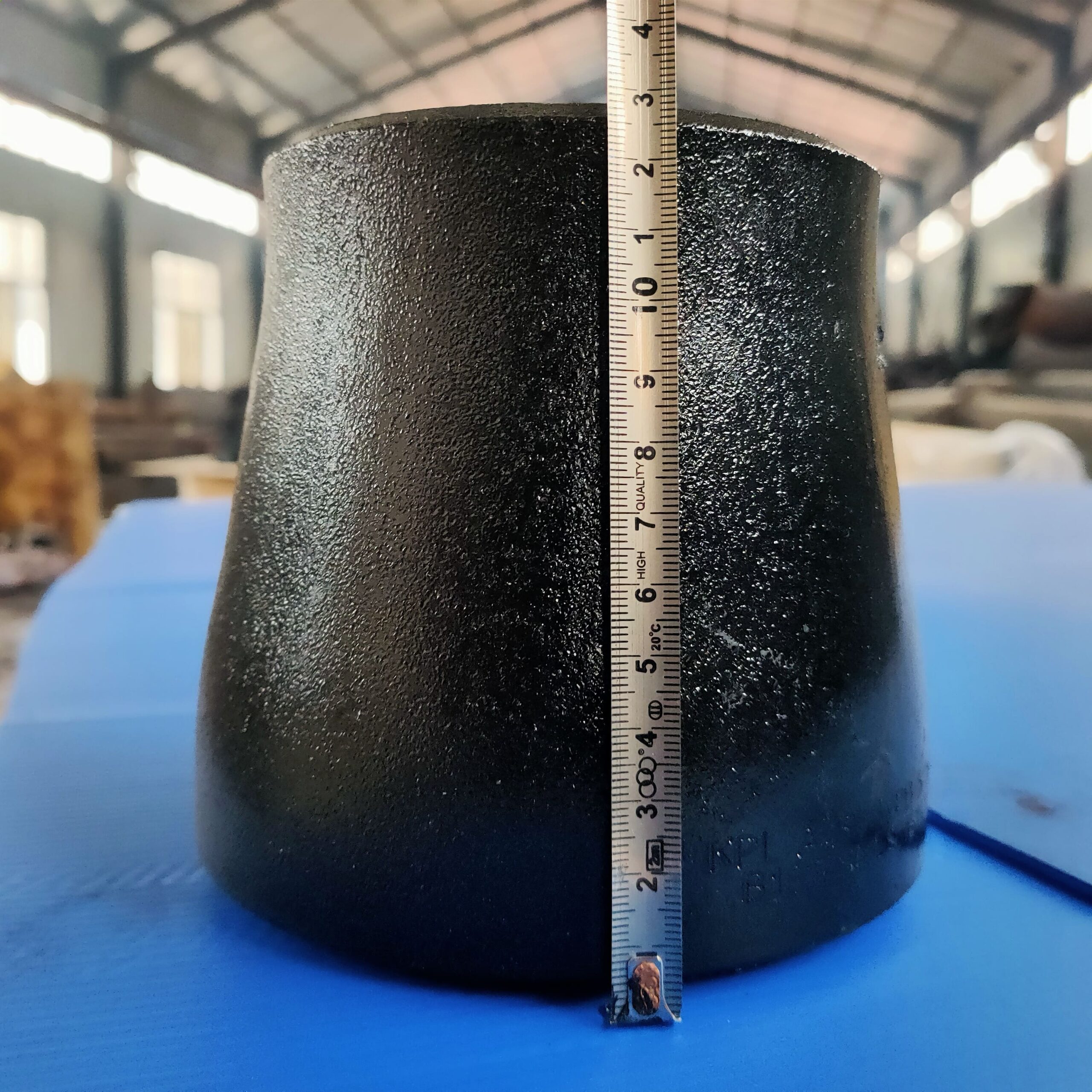

UNS S31803 Elbow Dimensions

Standard: ASME/ANSI B16.9

Size: 1/8″ to 24″

Thickness: Sch 10s, 20, STD, 40S, XS, 80S, 120, 160

Technical: Seamless and Weld Elbow

Surface: Pickling and Solution Heat Treatment.

Material Grades: UNS S 31803, S 32205, S 32550, S 32750, S 32760

Material of UNS S31803

UNS S31803 material is called the standard duplex steel. UNS S31803 90 degree elbow is commonly used type of duplex due to the low cost and interchangeability between austenitic steel needs and duplex steel needs.

Chemical Composition

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Cr | Ni | Mo | N |

| ASTM A815 UNS 31803 | MIN | |||||||||

| MAX | 0.03 | 2.0 | 0.030 | 0.020 | 1.0 | 23 | 6.5 | 3.5 | 0.20 |

Mechanical properties

| MATERIAL | ASTM A815 UNS 31803 |

| T.S (MPA) | 620 min |

| Y.S (MPA) | 450 min |

| EL % | 20 min |

| R/A % | |

| HARDNESS | 290 max |

How to Calculate Weight of 90 Degree Elbow

Calculation Formula : W=0.0387 * S( D – S ) * R / 1000

- W = Weight (kg/piece).

- S = Thickness in mm.

- D = Nominal Diameter in mm.

- R = Radius

For example” 90 Degree Elbow SR 10″ x 10mm Thickness BW ASTM A403 WP316 ASME B16.9″

From above information, we can know OD is 10″ which is 273mm. SR means 1D that is 1 x 273mm. Thickness is 10mm. Let’s take these data into formula.

0.0387 x 10 x (273 – 10) x 1 x 273 / 1000 = 27.8kg/pcs.