Home » Forged Steel Fittings » Pipe Swage Nipple Carbon Steel Pipe Fittings

Pipe Swage Nipple Carbon Steel Pipe Fittings

Pipe Swage Nipple (also known as reducing nipple) is divided into tubing sub and casing sub. Flanging nipple in pipe connection is commonly used with flange.

Contact US

Get Price

Share:

Content

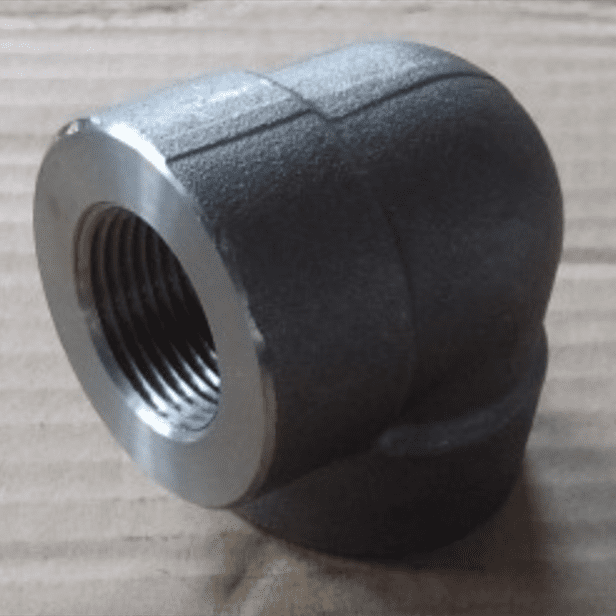

Swaging nipple (also known as reducing nipple) is a forged pipe fitting. It is used to change the diameter of the pipe and connect two pipes of different sizes.

Shapes:

Concentric: Concentric swage nipple is mainly used for vertical pipeline.

Eccentric: eccentric swage nipple is mainly used in horizontal pipelines.

End Types:

PBE=Plain Both Ends

PLE=Plain Large End

PSE=Plain Small End

POE=Plain One End

TOE=Thread One End

TBE=Thread Both Ends

TLE=Thread Large End

TSE=Thread Small End

BBE=Bevel Both Ends

BLE=Bevel Large End

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

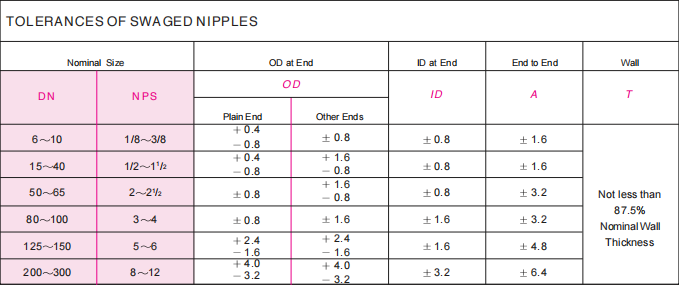

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

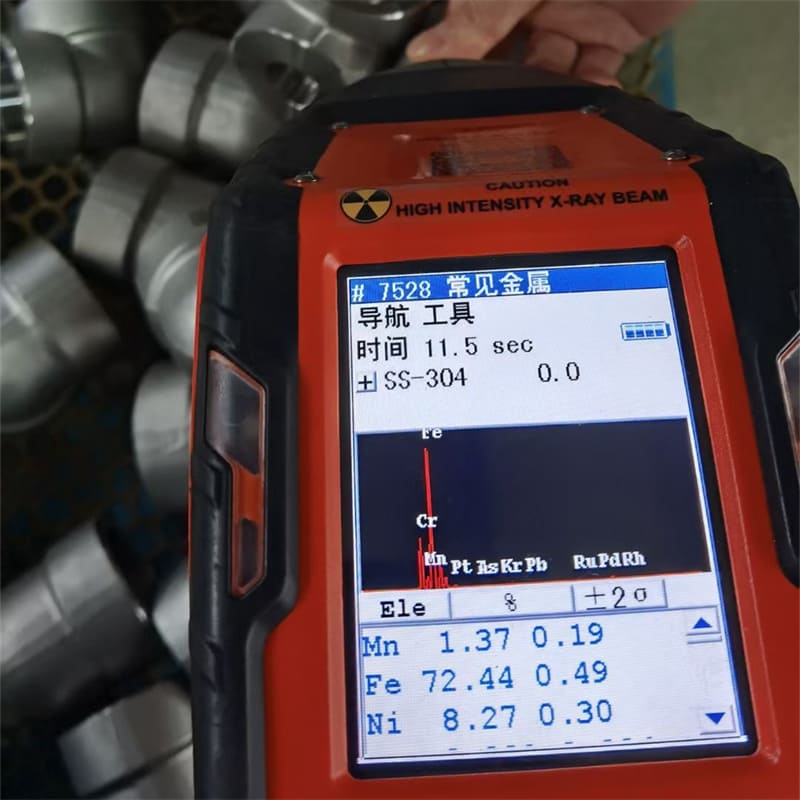

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

- Water supply facilities

- Food industrial pipelines

- Chemical industrial pipelines

- Electronic industrial pipelines

- Air conditioning facility pipelines

- Agriculture and garden production transportation

- Pipeline network for solar energy facility

Inquiry

More Threaded Pipe Fitings