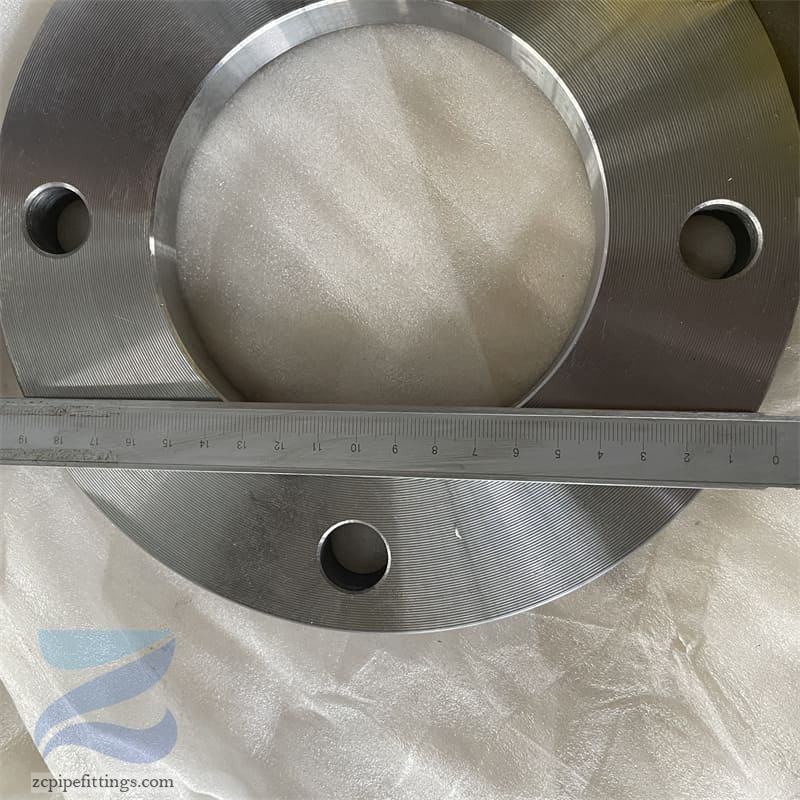

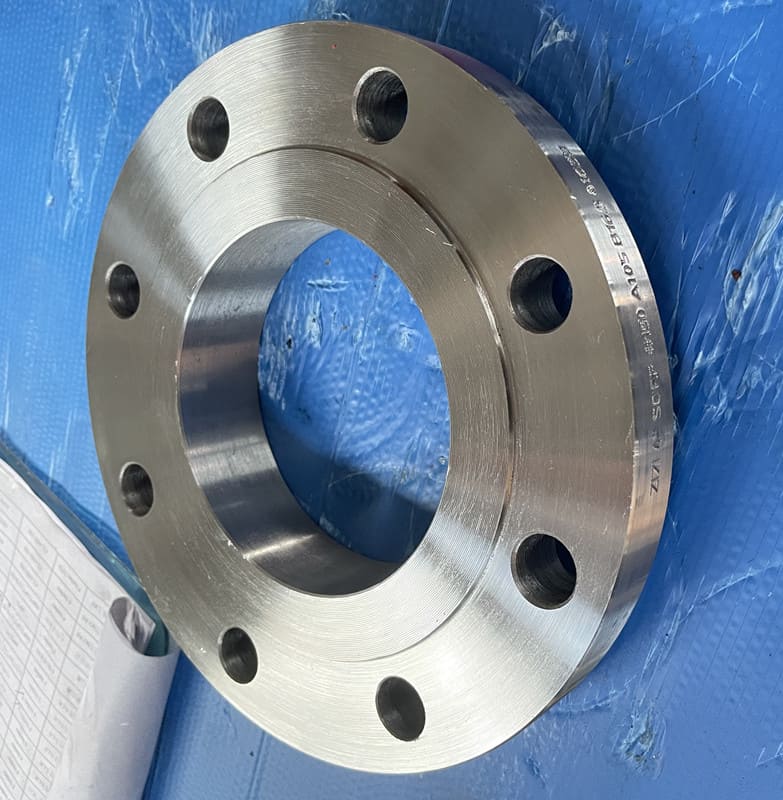

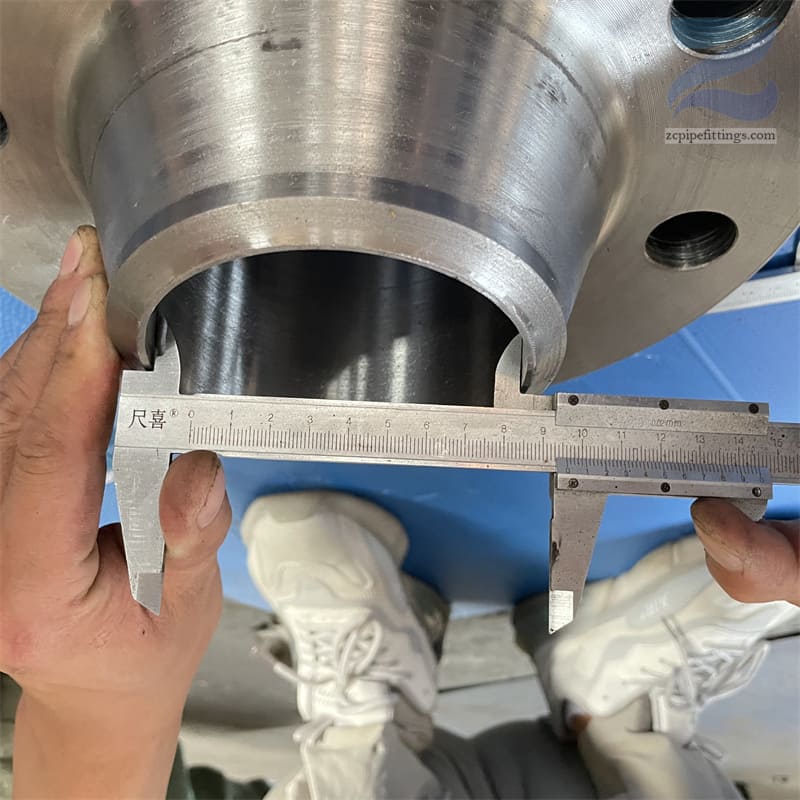

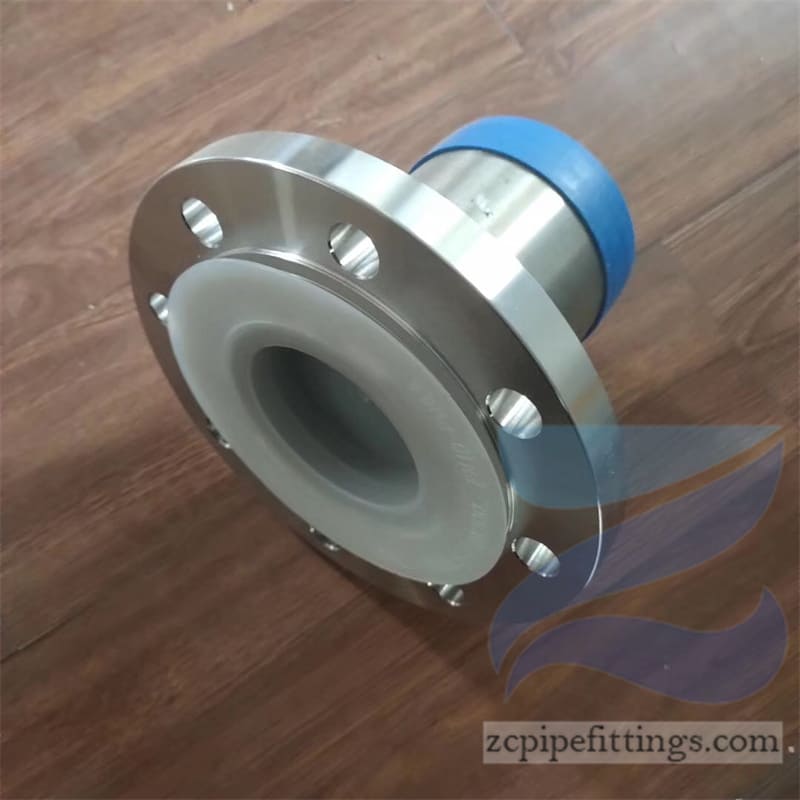

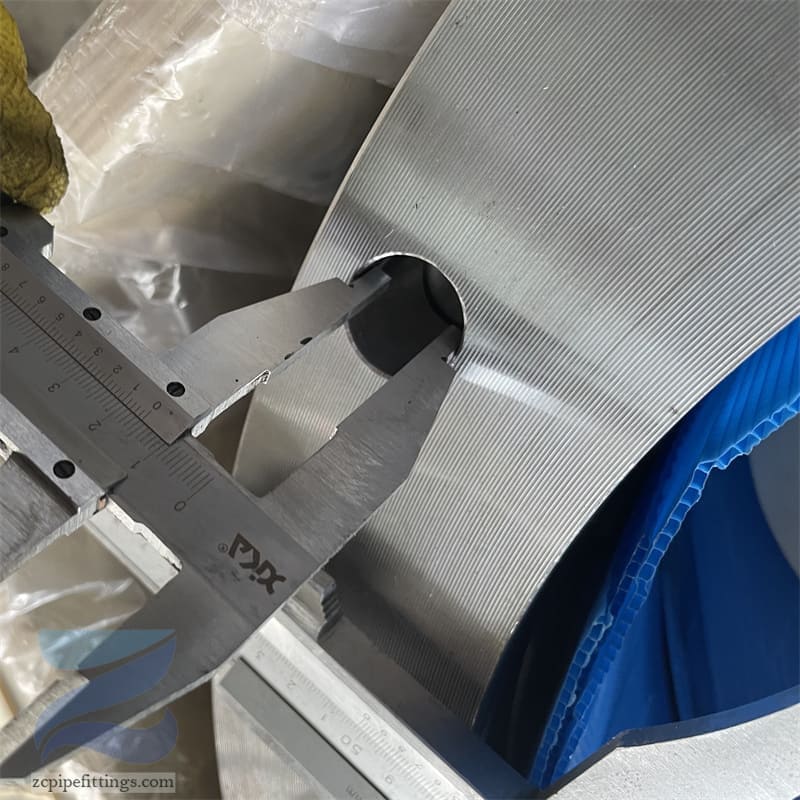

Pipe Flange: Slip-On Flange, 316/316L Stainless Steel, 2 in Pipe Size, 6 1/2 in Flange

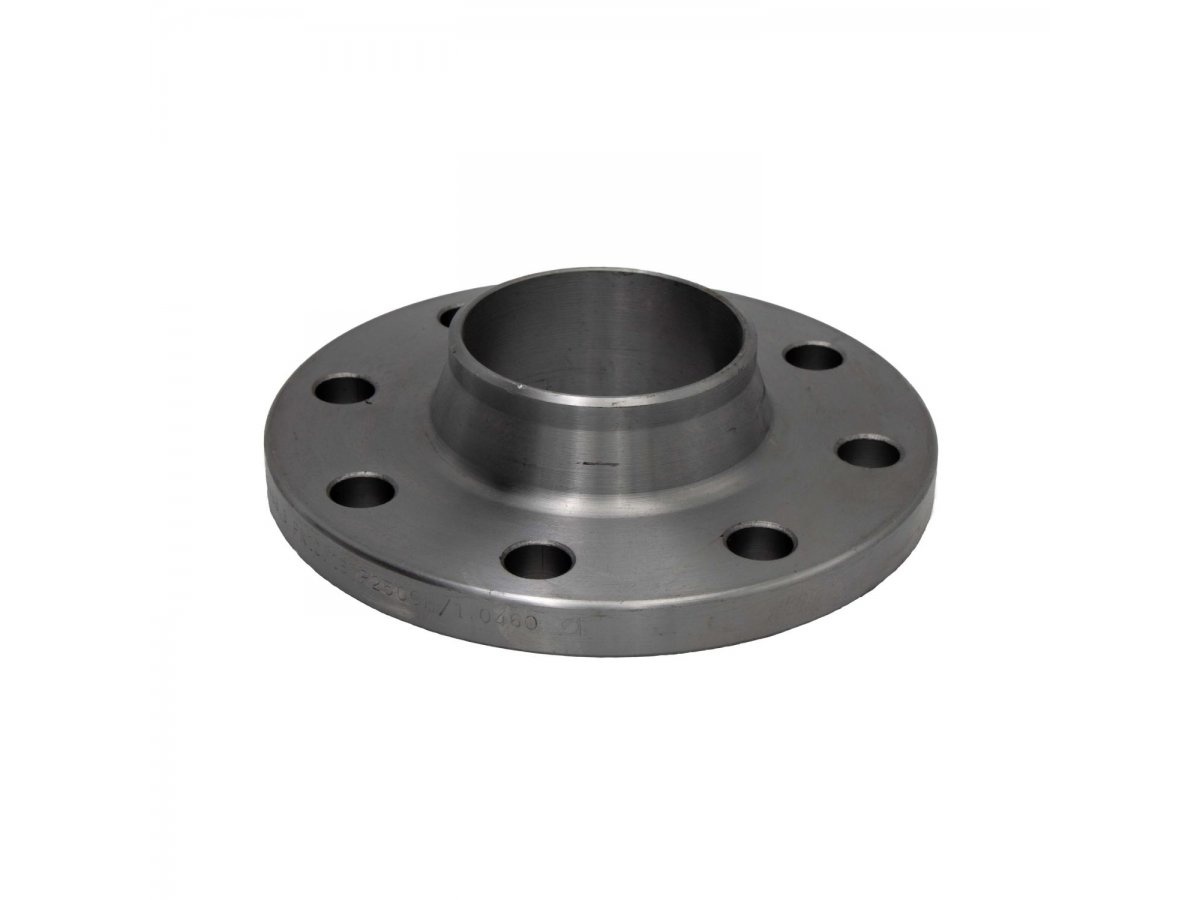

It is used to insert the pipe into the inner hole of flange, as the flange inner diameter is little bigger than the pipe’s outer diameter, pipe and flange could be connected by lap welding at the top and bottom of the flange. The slip-on flange is a simple and excellent alternative to a weld neck as it does not have a weld bevel, and therefore allows the pipe to be adjusted in length relative to its position of the flange.

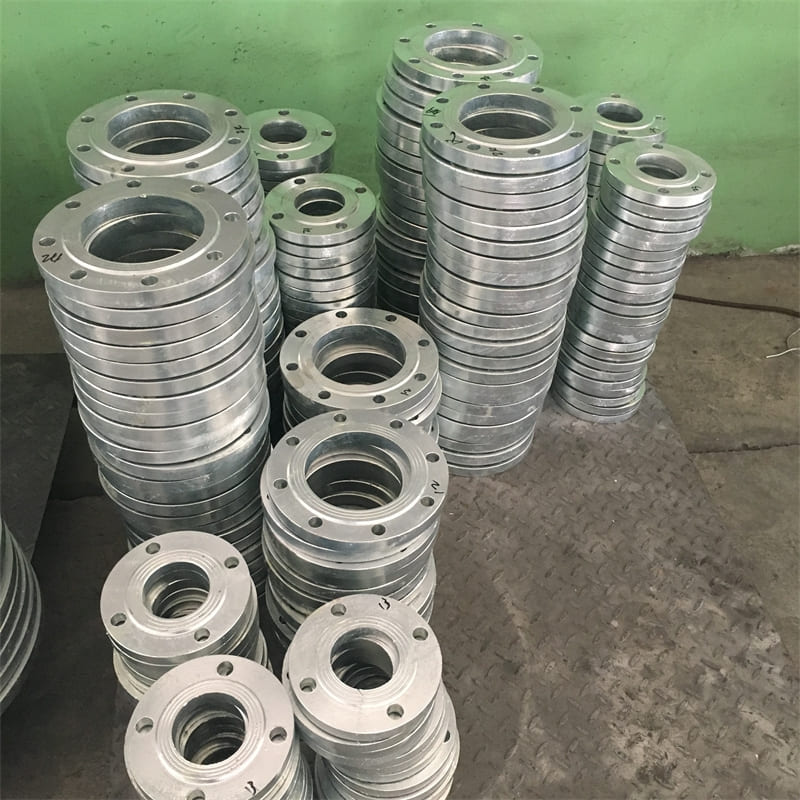

Slip on flange also named as SO flange. SO flanges slip over pipes and are designed to bit slightly bigger on the inside than the pipe. They connect to the pipe through a fillet weld at the flange top and bottom. It is used to insert the pipe into the inner hole of flange, as the flange inner diameter is little bigger than the pipe’s outer diameter, pipe and flange could be connected by lap welding at the top and bottom of the flange. The slip-on flange is a simple and excellent alternative to a weld neck as it does not have a weld bevel, and therefore allows the pipe to be adjusted in length relative to its position of the flange. The bore of the slip on will give ample amount of space for the matching pipe. This allows for enough working space for the welder and fabricator to make the connection.Slip-On flanges are commonly lower in price than weld-neck flange.However, customers should bear in mind that this initial cost saving may be diminished by the additional cost of the two fillet welds required for proper installation.

Applications

- Water supply facilities

- Food industrial pipelines

- Chemical industrial pipelines

- Electronic industrial pipelines

- Air conditioning facility pipelines

- Agriculture and garden production transportation

- Pipeline network for solar energy facility