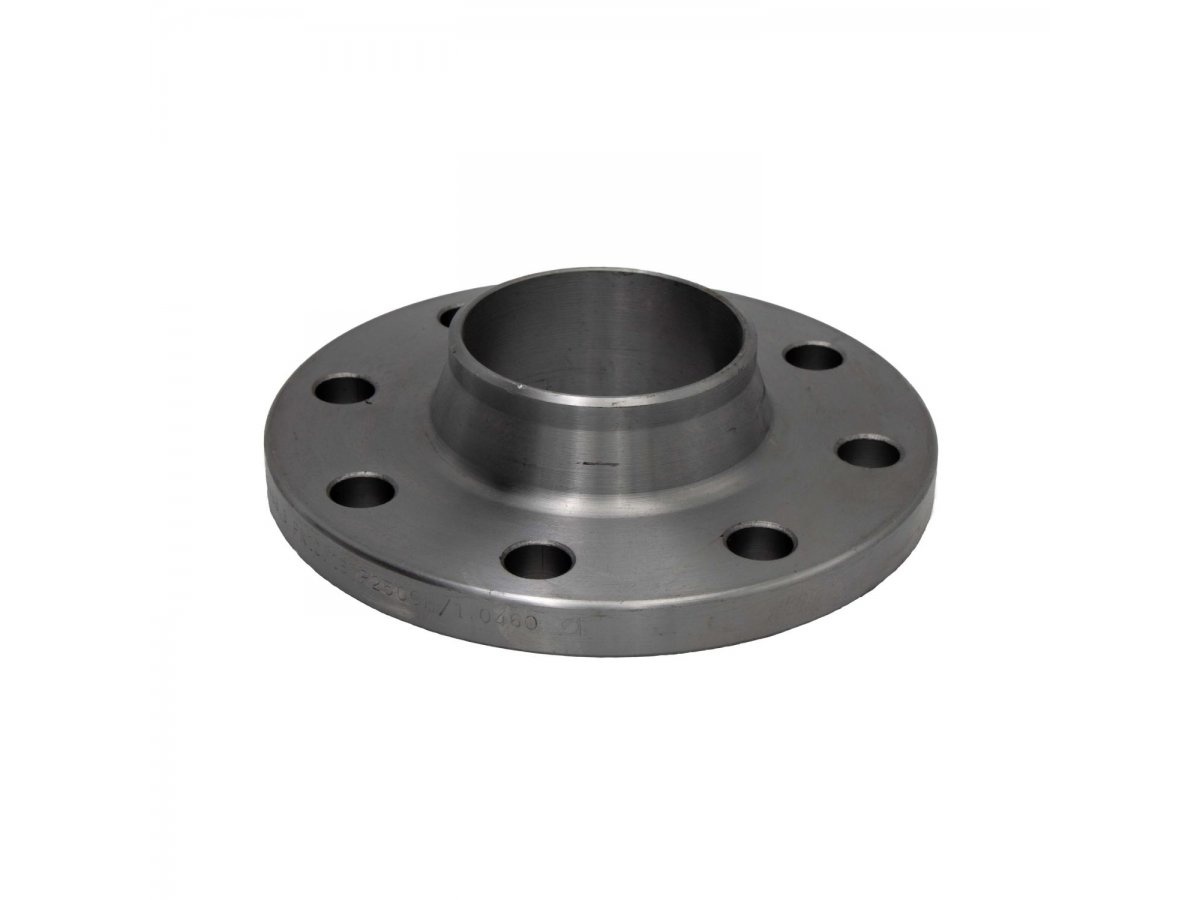

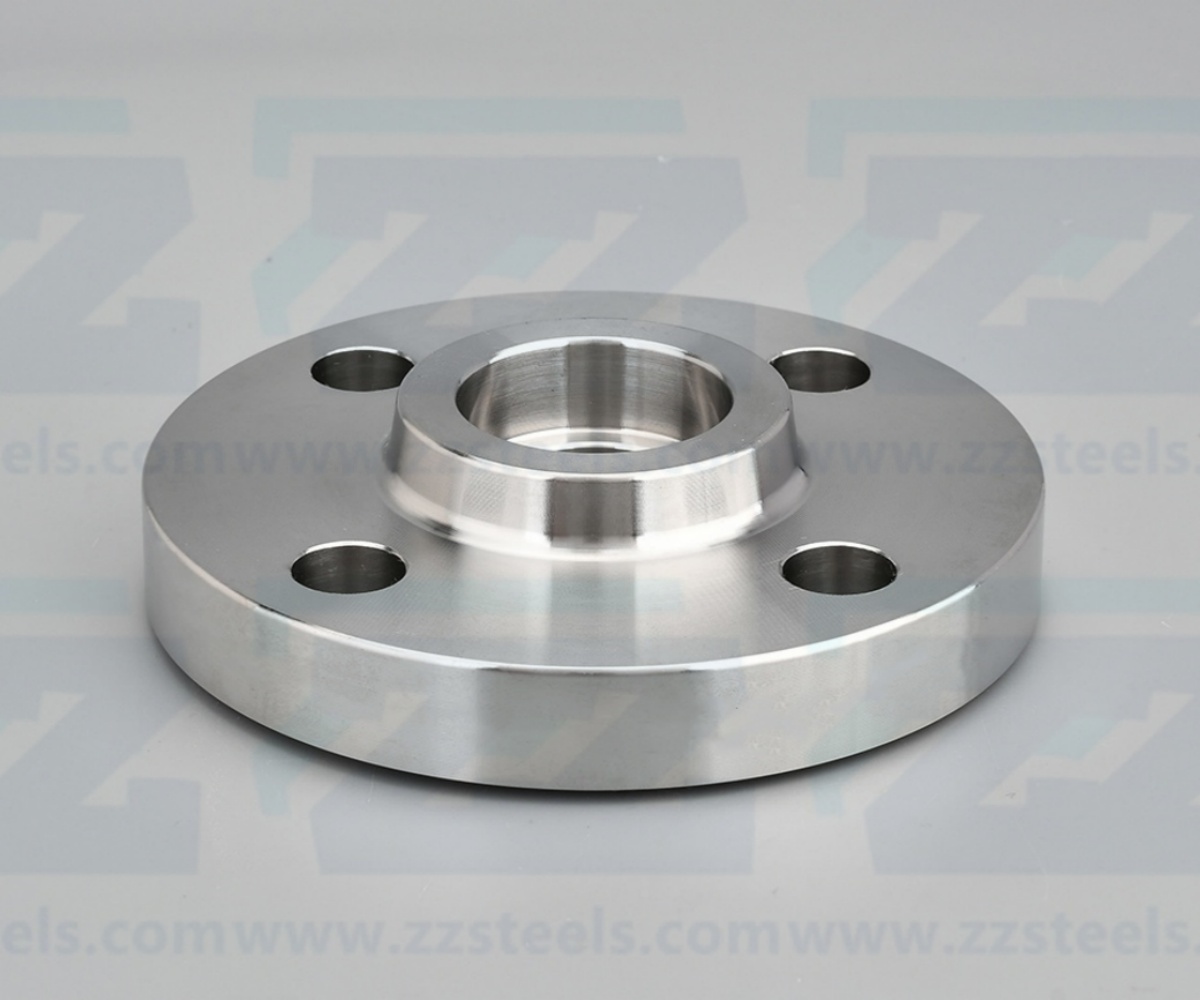

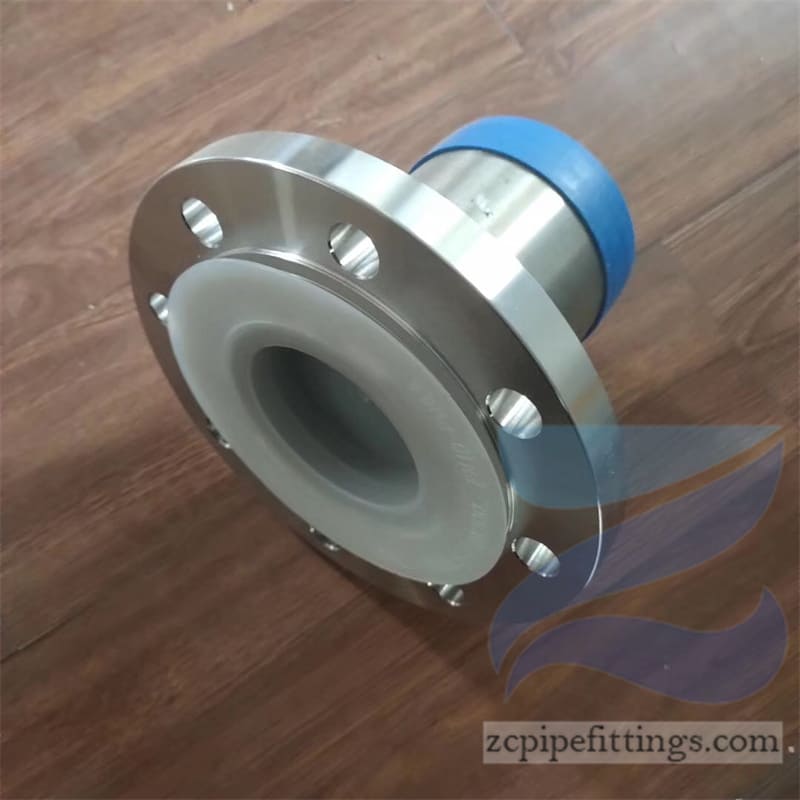

P280GH Weld Neck Flange

P280GH weld neck flange refers to a flange connection method that uses P280GH material as the base material and forms one or more layers of P280GH material welding layers on the flange surface through the butt welding process to improve the flange’s high temperature resistance, high pressure resistance and corrosion resistance.

P280GH weld neck flange refers to a flange connection method that uses P280GH material as the base material and forms one or more layers of P280GH material welding layers on the flange surface through the butt welding process to improve the flange’s high temperature resistance, high pressure resistance and corrosion resistance. This flange connection method is usually used in pipeline systems that need to withstand high temperature and high pressure, such as nuclear power, petrochemical and other fields.

P280GH is a carbon steel grade with specific high temperature performance, and its implementation standards have important guiding significance for the production and use of materials. It has good impact toughness and welding performance, and is often used to manufacture equipment parts that need to withstand high temperature and high pressure, such as the main steam system of steam generators in the nuclear power field, water supply flow control systems, and rolled pipe fittings or forged pipe fittings of auxiliary water supply systems.

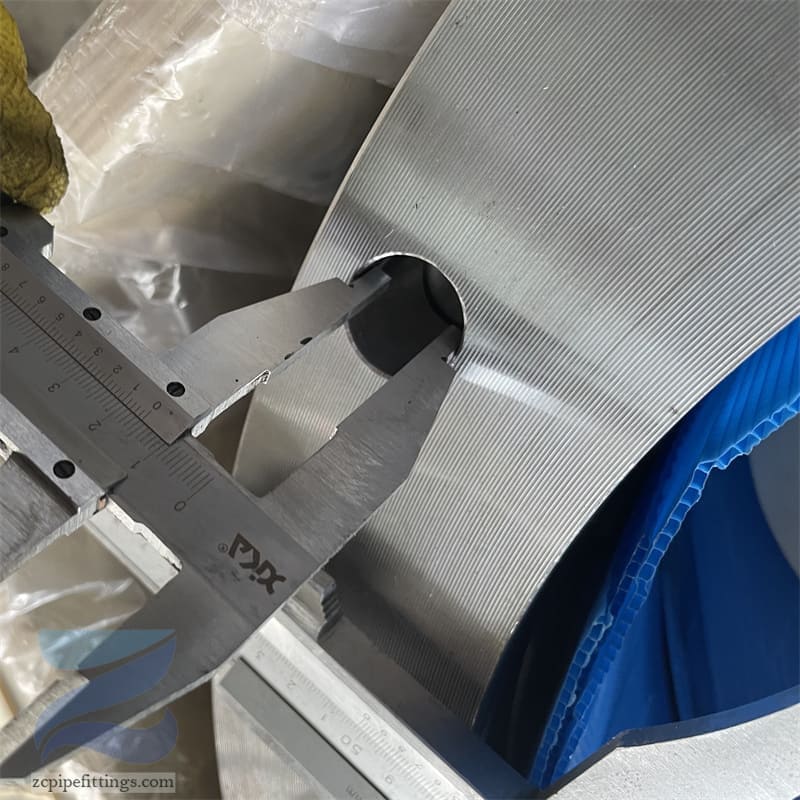

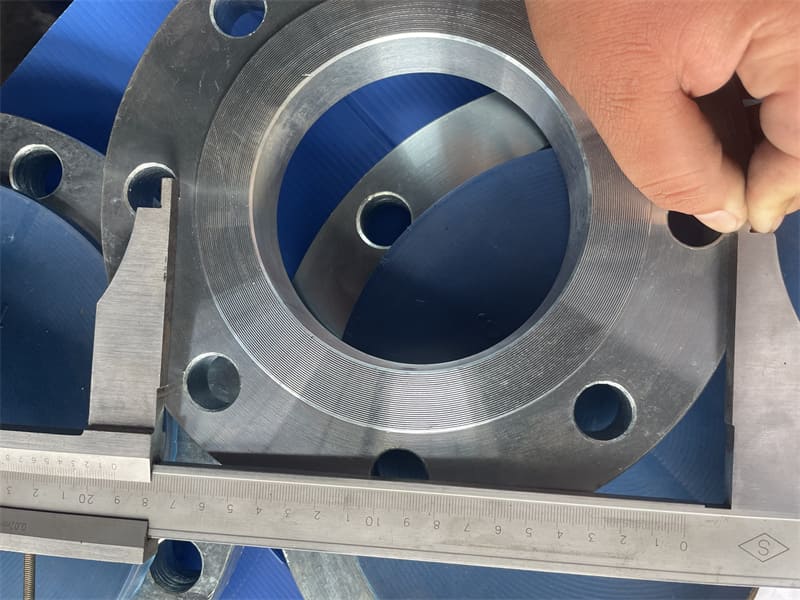

Specification of P280GH Flange

| Material Specification Of : | P280GH Flange |

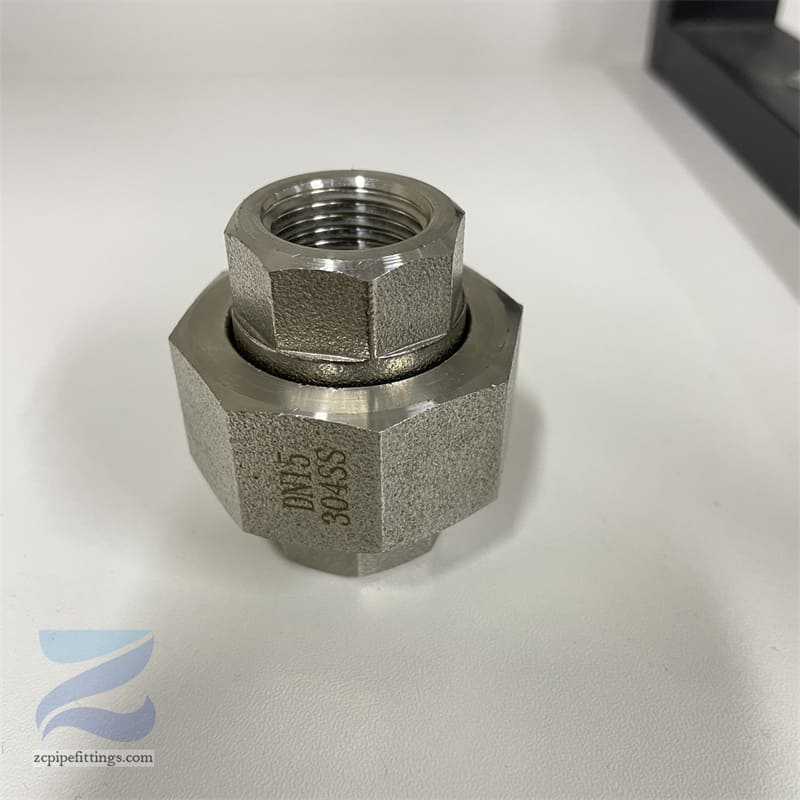

| Common Types Of Flanges: | Slip On (SORF), Weld Neck (WNRF), Blind (BLRF), Lap Joint (Loose), Threaded (NPT), Socket-Weld (SWRF) |

| Special Types Of Flanges : | Nipoflange, Elboflange, Latroflange, Swivel Flange, Expanding Flange, Reducing Flange, Weldoflange |

| European Standard Flanges | JIS B2220 Flanges (5k to 30k) and KS1503 flanges |

| Russian-Standard Flanges | GOST 12820 / 12821-80, DIN, UNI, EN 1092-1 |

| Standard Cover : | pressure ratings & temperature ratings, materials, marking, dimensions, weight, tolerances, testing |

| Contact Faces | RTJ (Ring Type Joint), FF (Flat Face), RF (Raised Face), T/G (Tongue And Groove ), M/F (Male And Female) |

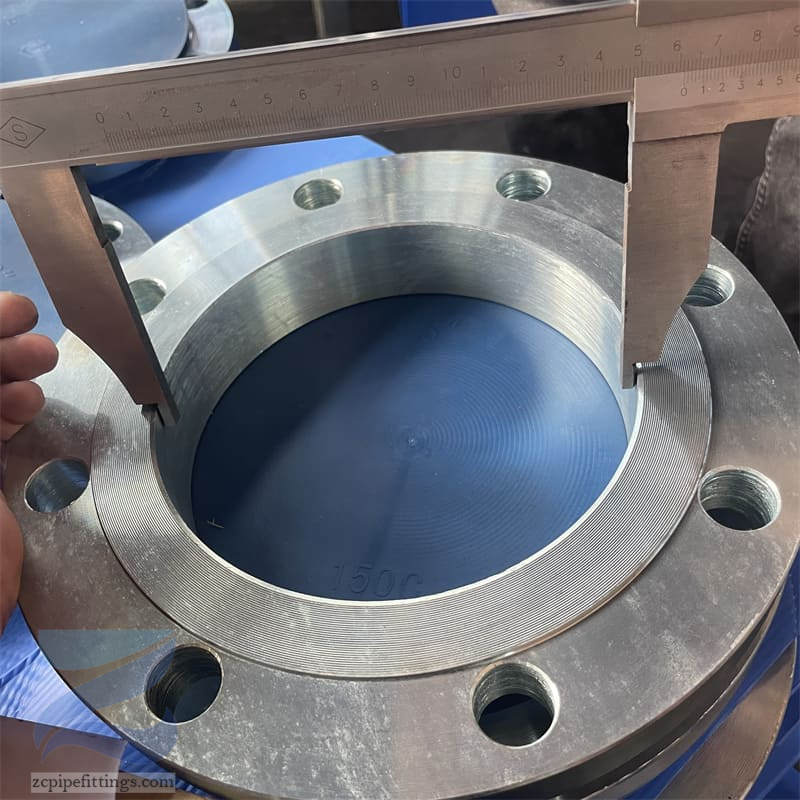

| Size Chart | Normal Pipe Size 1/2 to NPS 24″ |

| Thickness | Normal Pipe Size ≤ 18 |

| Bore Diameter | Normal Pipe ≤ 10 |

| Flanges Standards | EN 1092-1, JIS, ASME B16.5, ASME B16.47 type A, UNI, DIN |

| Pressure Rating | Class 150 To Class 2500 |

| High Temperature | Above 200°C (400°F) For Class 150 Or Above 400°C (750°F) |

| Low Temperature | Above -29 Degree C (−20°F) |

Material for Steel Pipe Flange

Stainless Steel Flange

ASTM/ASME A/SA182 F304, F304L, F316, F316L, F321, F904L, F310S,DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409

Carbon Steel Flange

ASTM/ASME A/SA105 A/SA105N, DIN 1.0402, DIN 1.0460, DIN 1.0619,ASTM A350 LF2 / LF3, ASTM A694 / A694 F52 / F56 / F60 / F65 / F70 / F80

Alloy Steel Flange

ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91

Nickel Weld Neck Flange

ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205

Hastelloy Flange

ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3

Duplex Steel Flange

S31803 / S32205 / S32750 / S32760 ASTM A182 F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61

Aluminium Flange

5052 /6061/ 6063 / 2017 / 7075

Application of P280GH Weld Neck Flange

Petrochemical Industry

In the process of oil refining, there are a lot of high temperature and high pressure environments. For example, crude oil distillation units, catalytic cracking units, etc., the pipeline systems in which need to transport various petroleum products and chemical raw materials. P280GH weld neck flanges can ensure the reliability of pipeline connections and prevent medium leakage due to their good mechanical properties and high temperature and high pressure resistance. In chemical production, many reactions need to be carried out under specific pressure and temperature conditions. P280GH weld neck flanges can be used to connect synthetic ammonia reactors with related pipeline systems to ensure safe and stable transmission of reaction media within the system.

Power Industry

In thermal power plants, pipeline connections in steam generators, superheaters, reheaters and other equipment need to withstand high temperature and high pressure steam. P280GH weld neck flanges can meet the strength and sealing requirements of pipeline connections in such high temperature and high pressure steam environments, ensure the normal operation of the steam system, and improve power generation efficiency and safety.

In nuclear power plants, although the working medium and operating environment are different from those of thermal power plants, some pipeline systems also need to withstand certain pressures and temperatures.