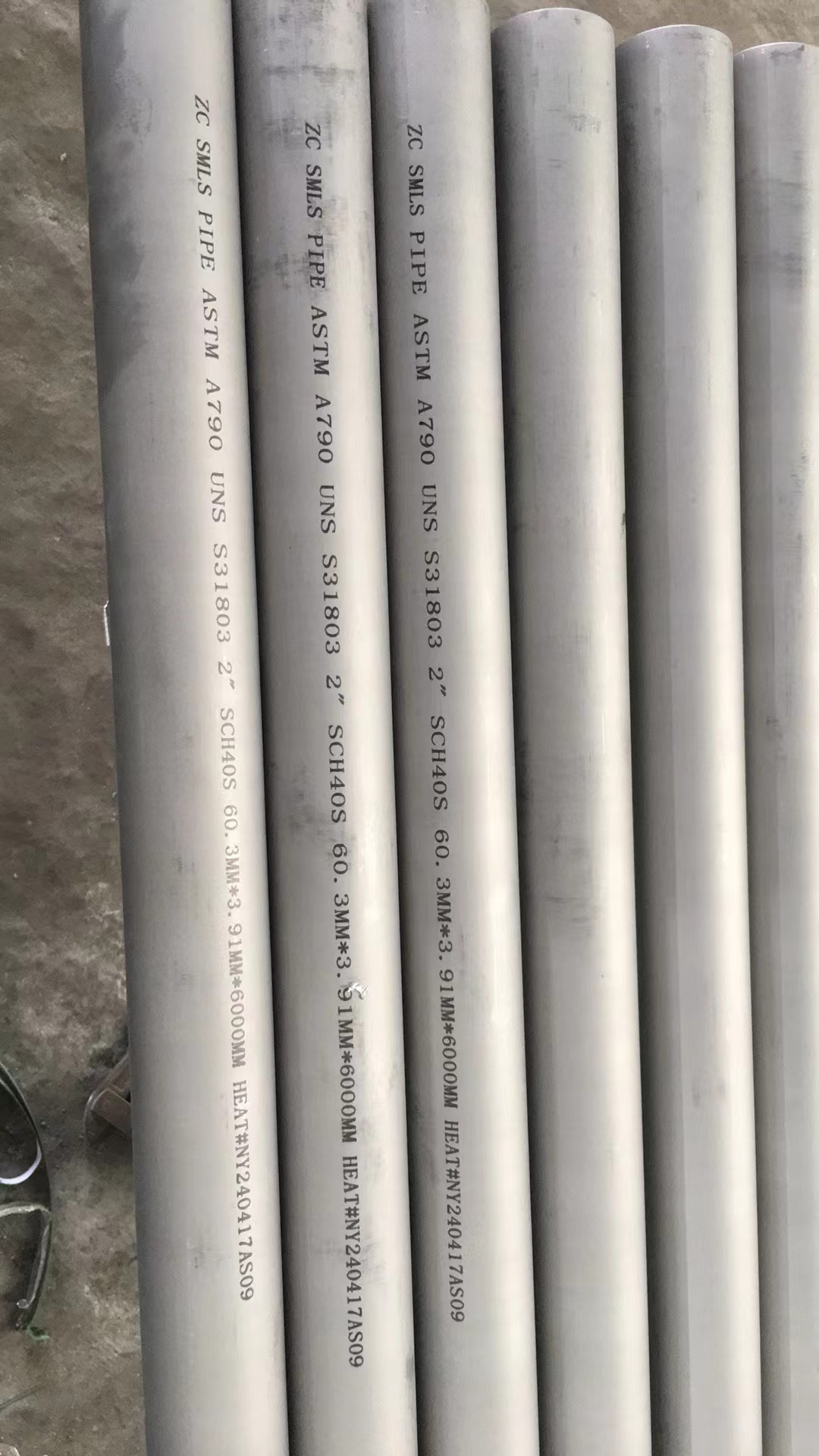

P265GH Carbon Steel Pipe

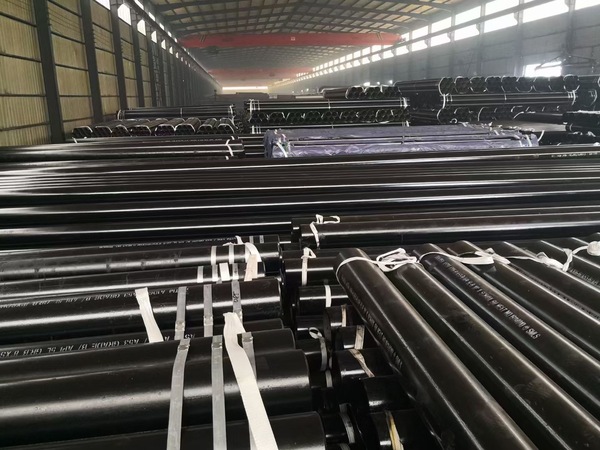

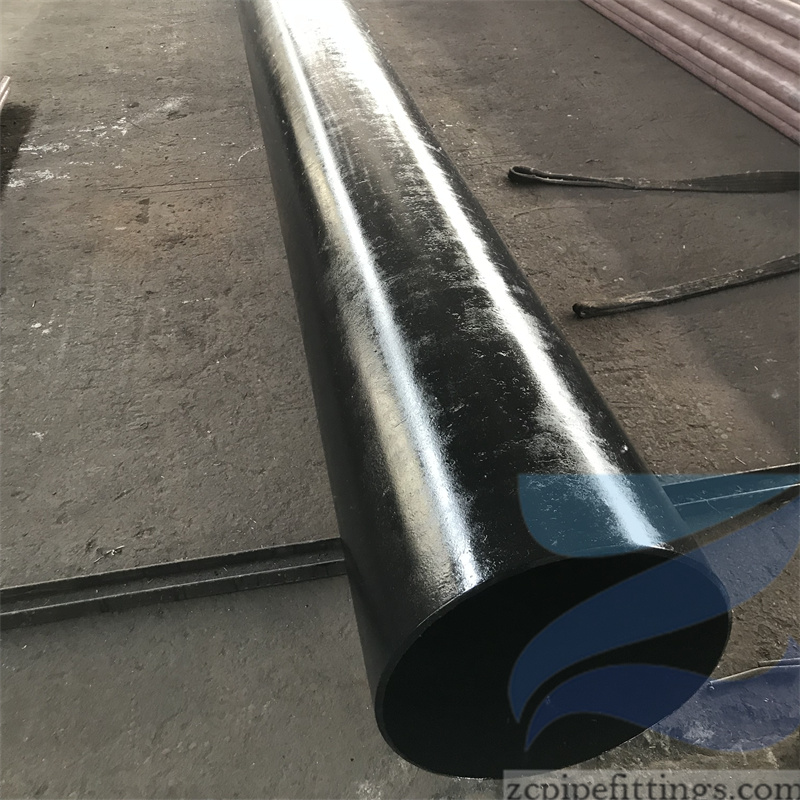

P265GH carbon steel pipe is a pressure vessel steel pipe with high strength, high toughness and excellent welding performance. It has excellent characteristics that make it widely used in various industrial applications.

P265GH carbon steel pipe is a pressure vessel steel pipe with high strength, high toughness and excellent welding performance. It has excellent characteristics that make it widely used in various industrial applications. P stands for pressure vessel steel pipe, 265 means that the yield strength of the steel pipe is not less than 265MPa, and GH means that the steel pipe has good toughness and welding performance.

In the steel industry, standards play a vital role in ensuring the quality, compatibility and safety of materials. An important standard in this field is EN 10216-2, which outlines the technical delivery conditions for seamless non-alloy and alloy steel pipes.

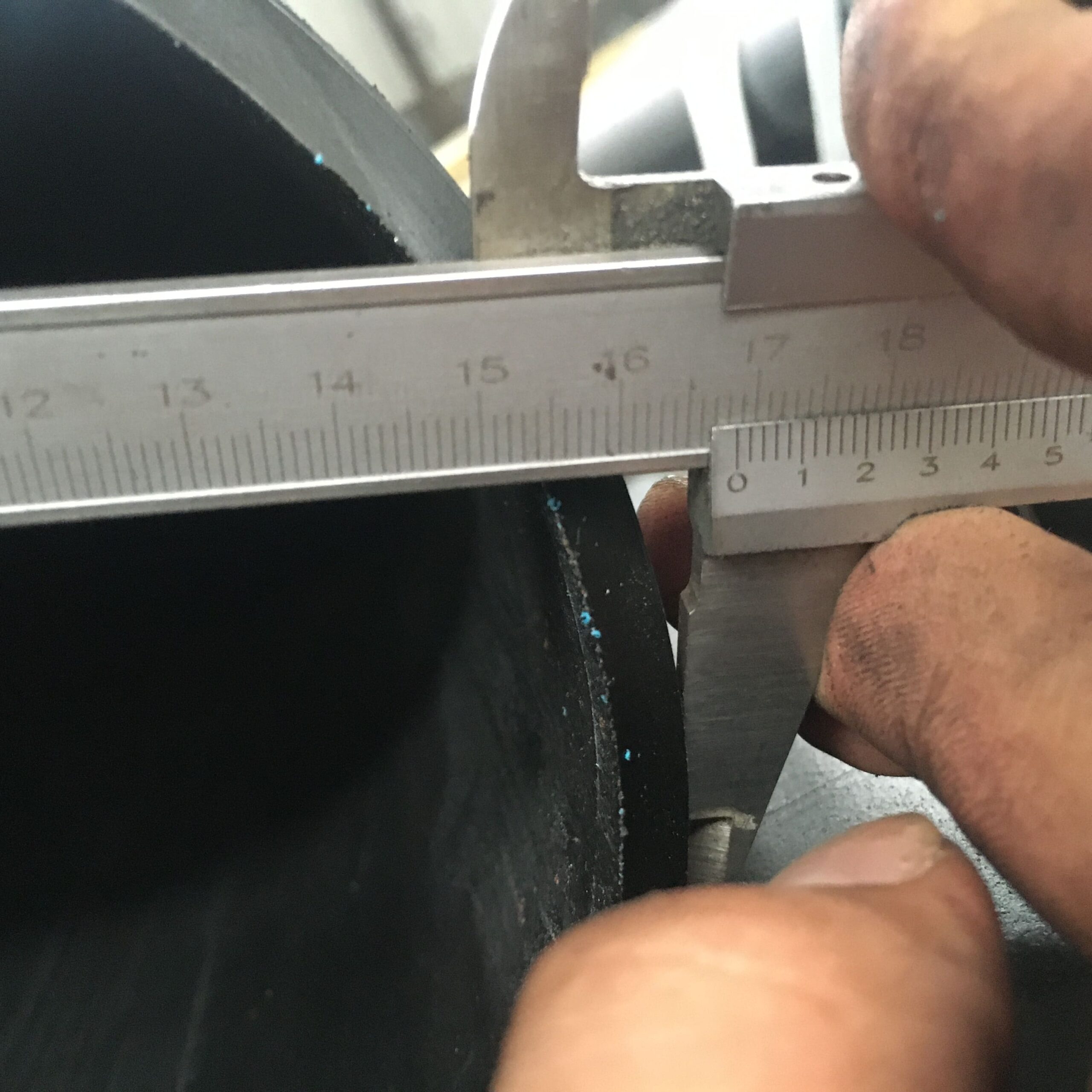

Dimensional tolerances of EN 10216-2

Tolerances for outside diameter and wall thickness

| Outside Diameter D mm

|

Tolerances on D

|

Tolerances on T for a T/D ratio | |||

| ≤ 0,025 | > 0,025 ≤ 0,050 |

> 0,050 ≤ 0,10 |

> 0,10 | ||

| D ≤ 219,1 | ± 1% or ± 0.5 mm whichever is the greater |

± 12,5% or ± 0.4 mm whichever is the greater | |||

| D > 219,1 | ± 20% | ± 15% | ± 12,5% | ± 10% a | |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | |||||

Tolerances for inner diameter and wall thickness

| Tolerances on inside diameter | Tolerances on T for a T/d ratio | |||||

| d | d min | ≤ 0,03 | > 0,03 ≤ 0,06 |

> 0,06 ≤ 0,12 |

> 0,12 | |

| ± 1% or ± 2 mm whichever is the greater | +2% ,0or + 4mm,0 | whichever is the greater | ± 20% | ± 15% | ± 12,5% | ± 10%a |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | ||||||

Tolerances for outside diameter and minimum wall thickness

| Outside diameter D mm | Tolerances on D | Tolerances on T min for a T min /D ratio | |||

| ≤ 0,02 | > 0,02 ≤ 0,04 |

> 0,04 ≤ 0,09 |

> 0,09 | ||

| D ≤ 219,1 | ± 1% or ± 0.5 mm whichever is the greater |

(+ 28%,0) or (+ 0.8 mm,0) whichever is the greater | |||

| D > 219,1 | + 50% 0 |

+ 35% 0 |

+ 28% 0 |

+ 22% a 0 |

|

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | |||||

Tolerances for inside diameter and minimum wall thickness

| Tolerances on inside diameter |

Tolerances on T min for a T min /d ratio |

|||

| d | d min | ≤ 0,05 | > 0,05 ≤ 0,1 |

> 0,1 |

| ± 1% or ± 2 mm whichever is the greater |

(+2%,0) or (+ 4 mm,0) whichever is the greater | + 35% 0 |

+ 28% 0 |

+ 22% a 0 |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | ||||

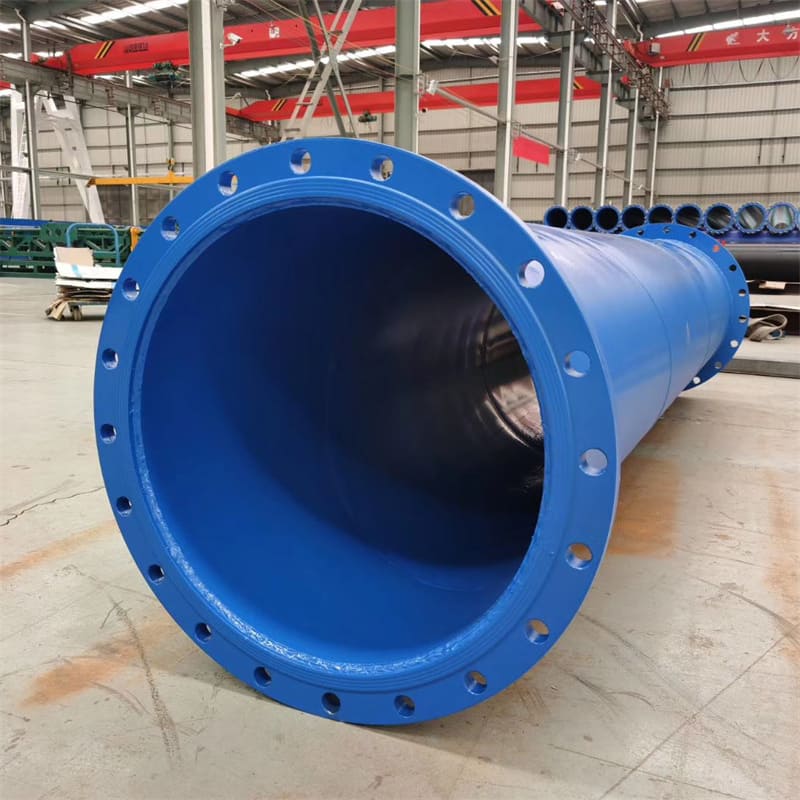

Application Range of P265GH Carbon Steel Pipe

Thermal power generation: In thermal power plants, P265GH carbon steel pipes are often used to manufacture various steam-water pipeline systems. For example, the main steam pipeline needs to transport the steam generated by the boiler to the turbine under high temperature and high pressure. With its good high temperature strength and good toughness, P265GH steel pipes can ensure safe and reliable and stable steam transmission during long-term operation to ensure the normal operation of power generation equipment.

Petrochemical: In refineries and chemical plants, P265GH steel pipes are widely used in various process pipelines. For example, the connecting pipelines of atmospheric distillation towers, vacuum distillation towers and other equipment in the process of petroleum refining need to transport oil products and chemical raw materials at different temperatures and pressures.

Gas transportation such as oxygen and nitrogen: In air separation units and related gas production and transportation companies, P265GH carbon steel pipes are used to transport industrial gases such as oxygen and nitrogen. During the production and use of these gases, strict requirements are placed on the material of the pipeline. Not only does it need to have a certain strength to withstand the pressure of the gas, but the material also needs to have good cleanliness and safety.

Heat exchanger pipes: In various industrial heat exchange equipment, P265GH steel pipes are often used as pipe materials for heat exchangers. Heat exchangers need to transfer heat between fluids at different temperatures, which requires that the pipe material must have good thermal conductivity and be able to withstand certain pressure and temperature changes.