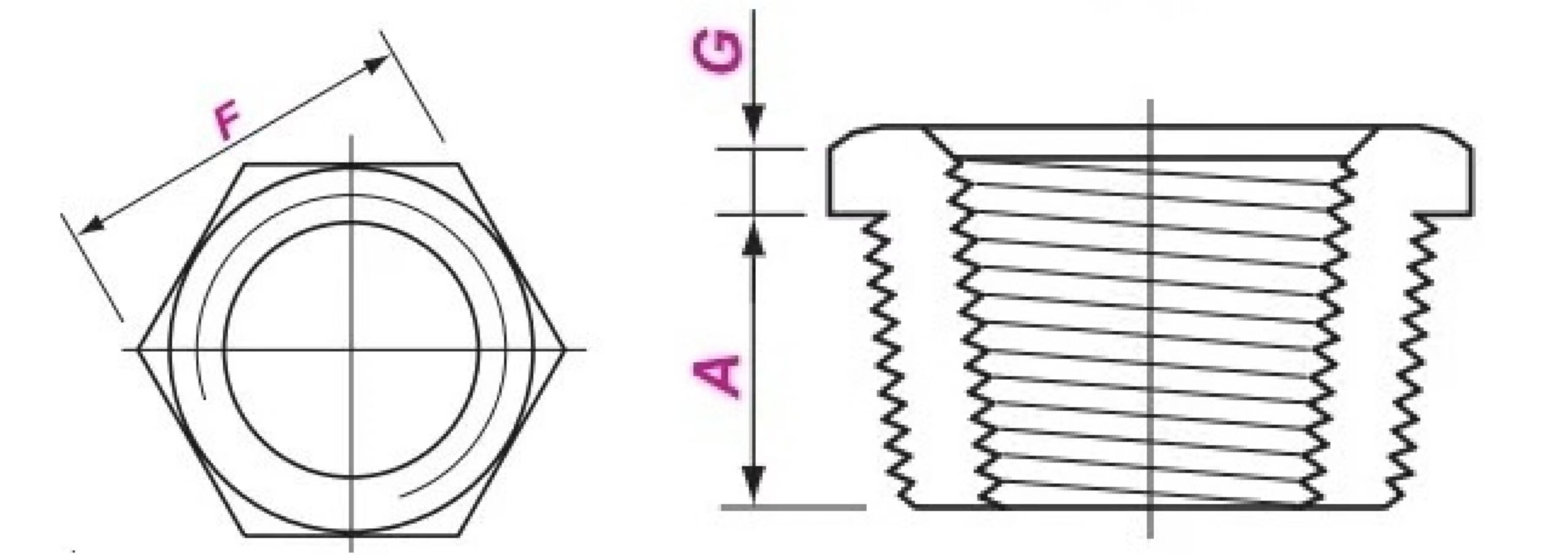

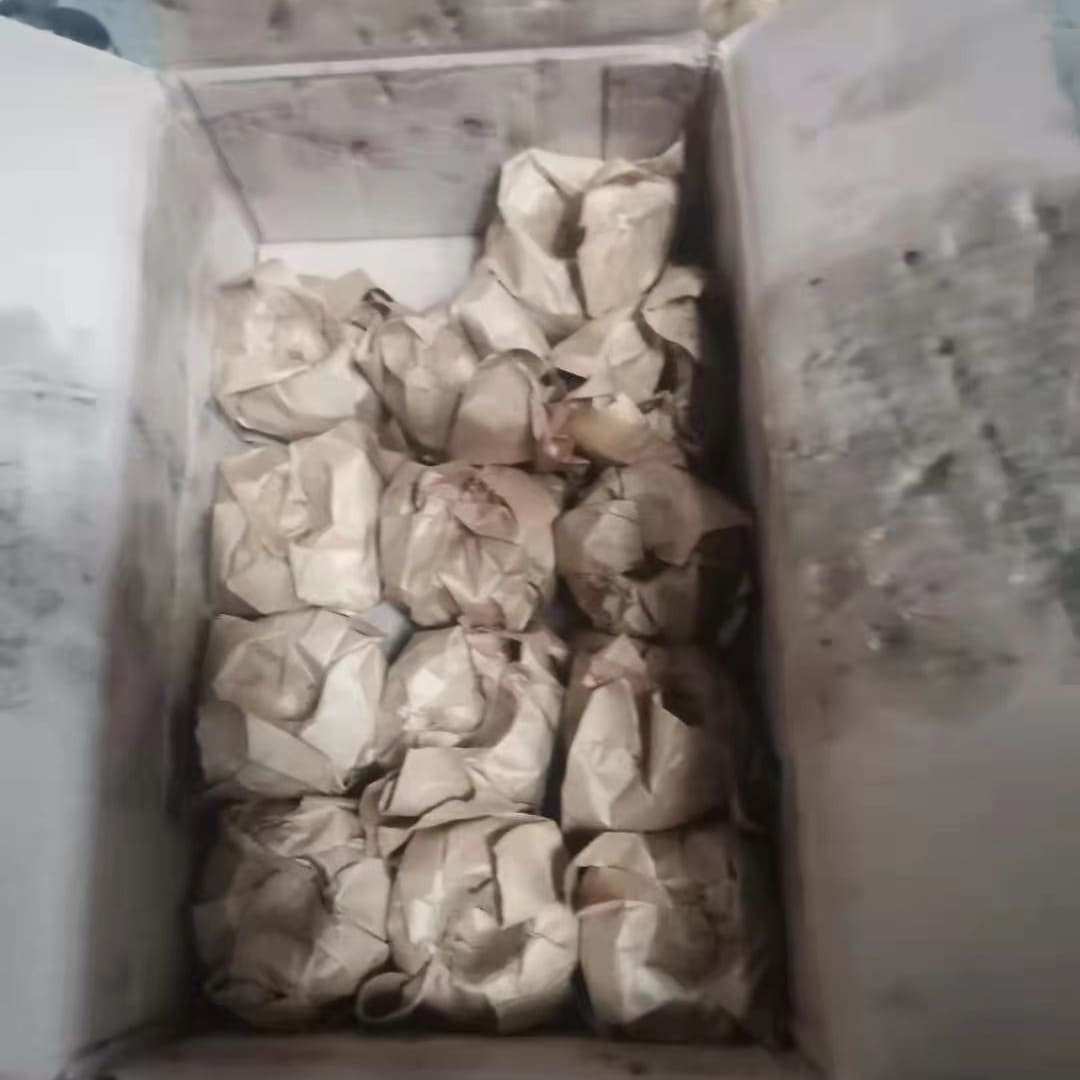

NPT A105 Bushing

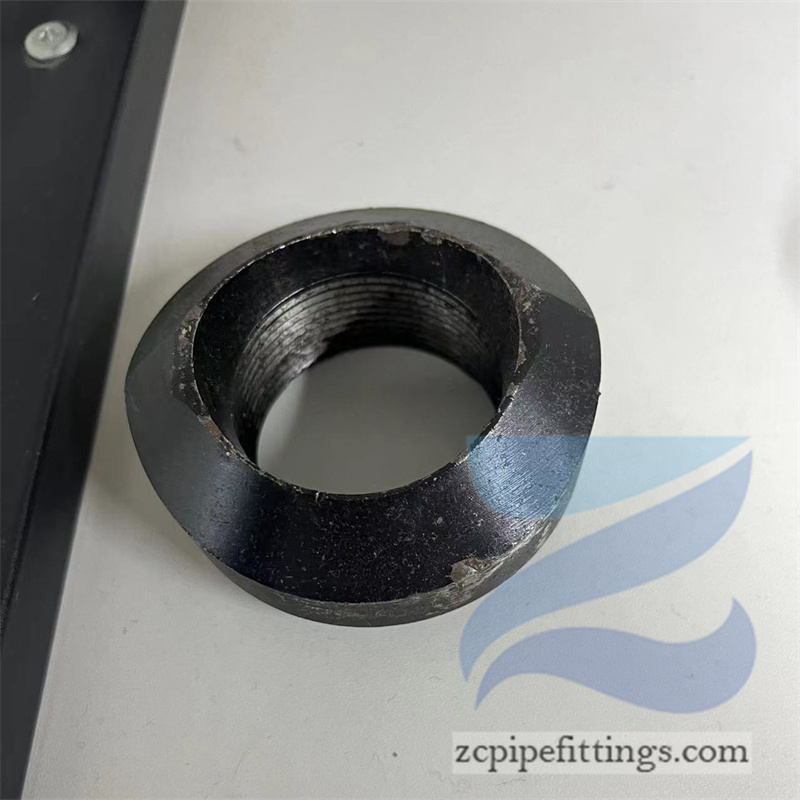

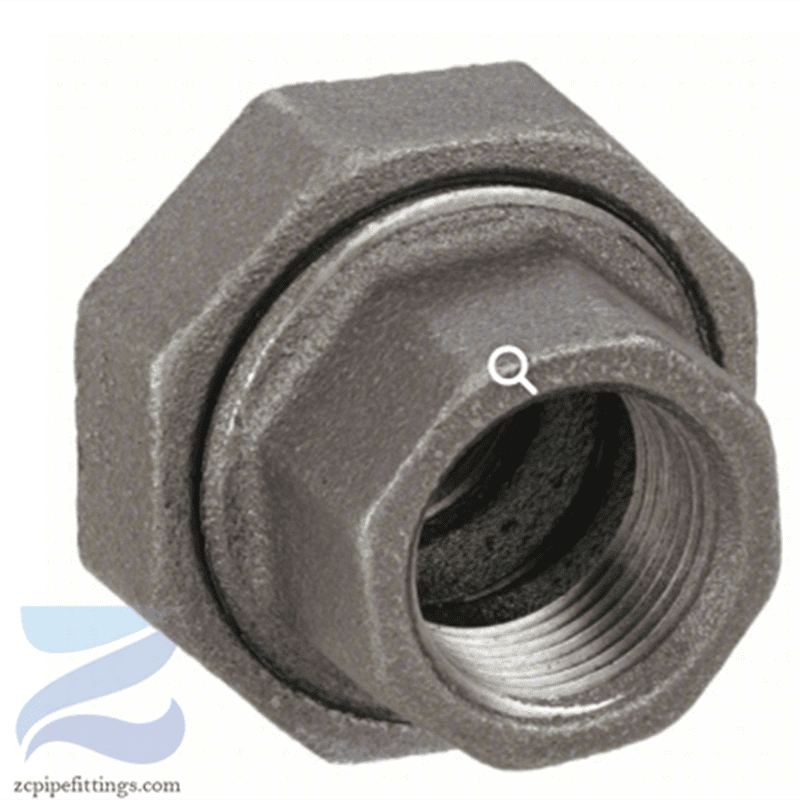

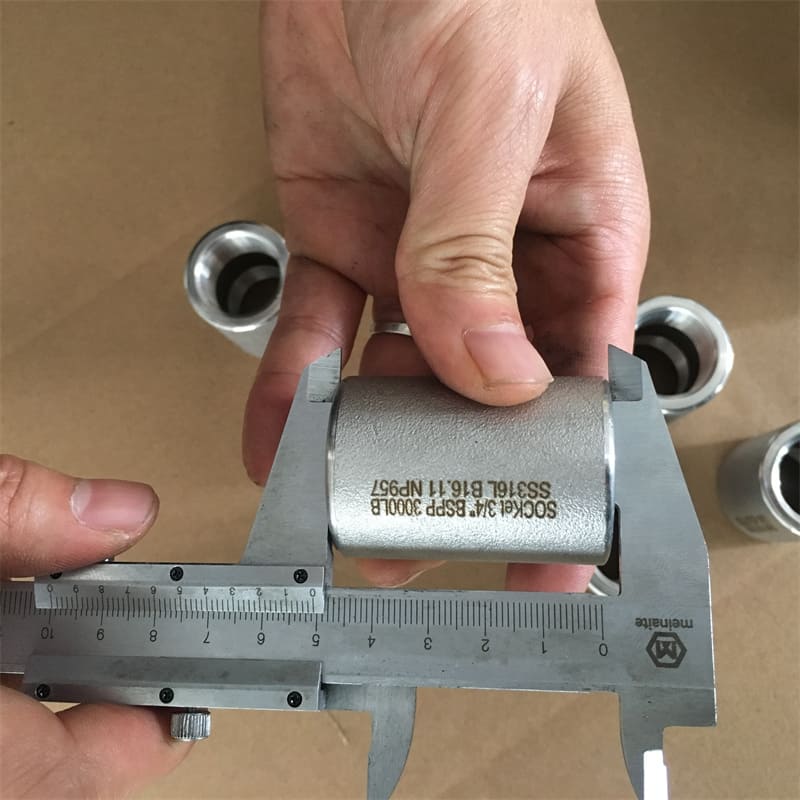

NPT A105 bushing is mainly used to connect two pipes of different diameters in the pipeline system or to correct the error in the pipeline installation. It is usually made of A105 carbon steel, has high strength and good corrosion resistance, and can withstand high working pressure.

NPT A105 bushing is mainly used to connect two pipes of different diameters in the pipeline system or to correct the error in the pipeline installation. It is usually made of A105 carbon steel, has high strength and good corrosion resistance, and can withstand high working pressure.

In the petrochemical industry, reliable connections are required between various fluid delivery pipelines of different diameters. Carbon steel threaded core bushings can be used to connect oil pipes, gas pipes, etc. of different diameters. For example, in the production process of an oil refinery, from a large crude oil delivery pipeline to a small processing equipment feed pipeline, a core bushing may be required to adjust the pipe diameter.

In the compressed air pipeline system of a mechanical manufacturing workshop, when the pipe diameters of the pipes connecting different equipment are inconsistent, a carbon steel threaded core bushing is an economical and practical connecting pipe fitting.