MSS SP-97 Olet Low Temp Carbon Steel ASTM A350 LF2 Weldolet

We manufacture and export Hiph Pressure Steel Pipe Fittings. MSS SP-97 is the standard of Olet which contains Weldolet, Sockolet and Threadolet. ASTM A350 LF2/LF3 is the grade of Low Carbon Steel Forged Steel Fittings.

MSS SP-97 is the standard of Olet which contains Weldolet, Sockolet and Threadolet. ASTM A350 LF2/LF3 is the grade of Low Carbon Steel Forged Steel Fittings.

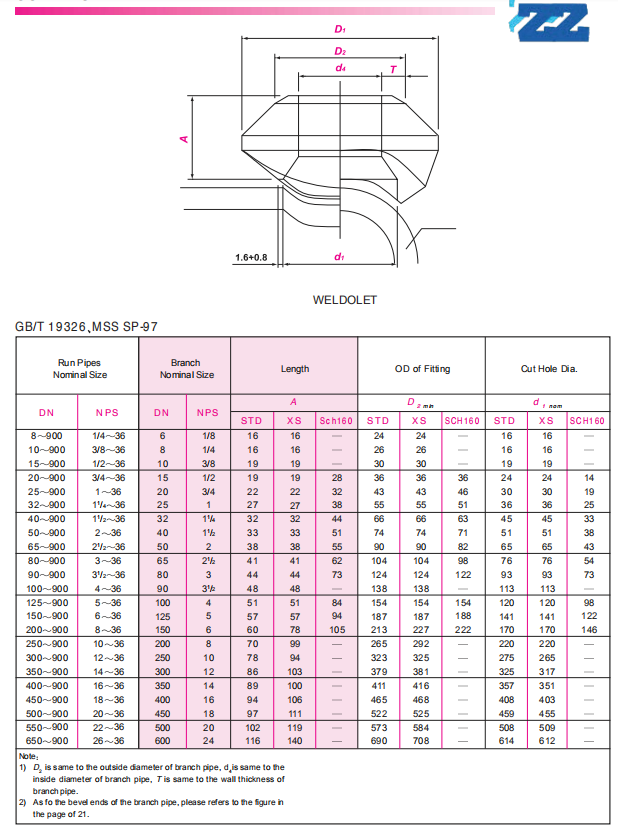

About the standard of Weldolet MSS-SP 97

The MSS-SP 97 specification covers the dimensions, the finishing, the tolerances, the testing methods and procedures, the marking, the material grades, and the minimum tensile strength requirements for 90-degrees integrally reinforced forged branch outlet fittings (welded, sock and threaded).

About the Low Temp Carbon Steel Fittings

Low Temperature causes harmful impacts on ductility of carbon steels, making steels more brittle and prone to failure. Therefore, we need to use special steel type to handle such situations that is low temp carbon steel, also abridged as LTCS.

Low Temperature Carbon Steel Grade

There are some types and grades for low temperature carbon steel pipe fittings, pipe and flanges.

• ASTM A350 Forged Fittings, Olet and Flanges.

• ASTM A420 Butt Weld Fittings.

• A333 Seamless and Welded Pipes

| Specification of Weldolet Fittings | |

| Size Range | 1/8″ – 4″ / DN6 – DN600 |

| Schedule Chart | STD, XS, SCH 80, SCH 160 |

| Standard | MSS SP-97 |

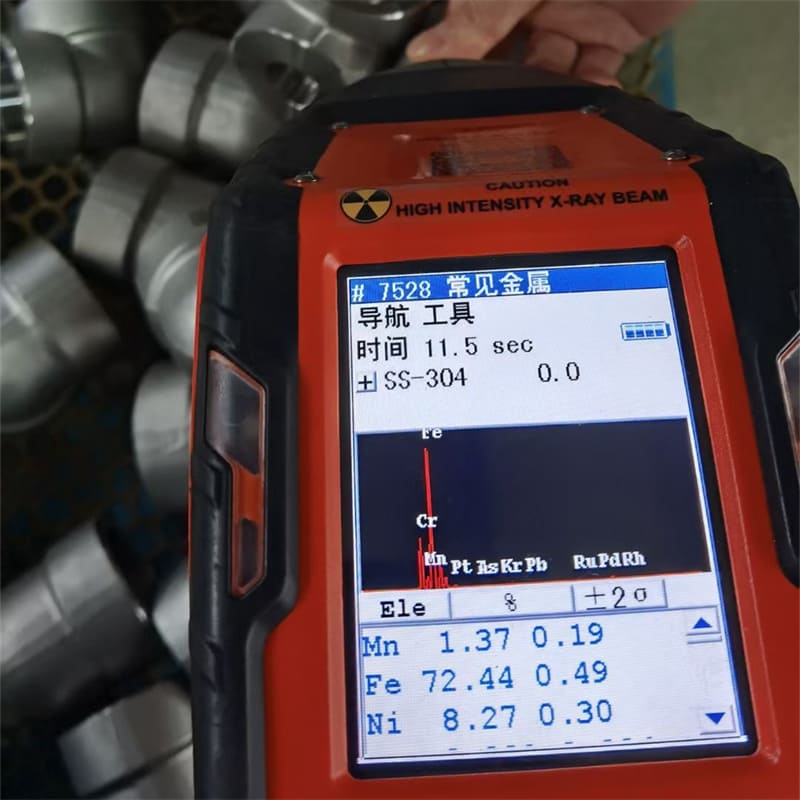

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

| Pipeline Steel | ASTM A694 F42/46/56/60/65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

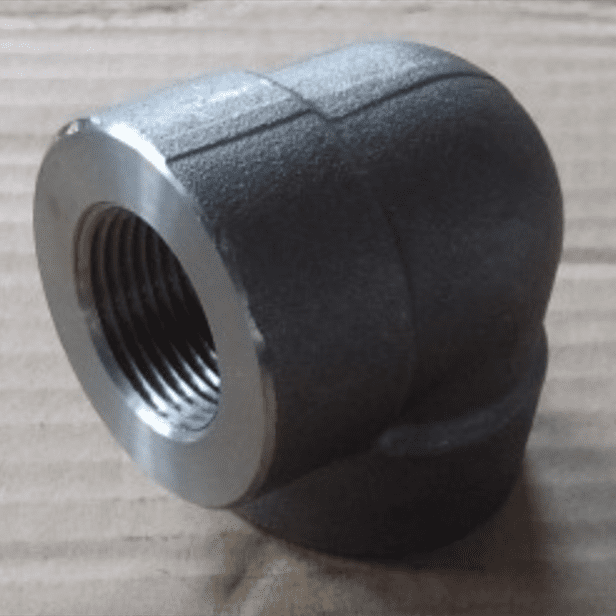

The Function of Weldolet

Weldolets are used to provide an outlet area from a larger to a smaller pipe connection point. The weldolet is welded to the larger pipe (the run) and connected to the smaller pipe (the branch).

Weldolet branch connection fittings are used for a variety of metal pipes such as stainless steel, chrome-moly and several other alloys.

Pipe branch fittings are used to create integrally reinforced connections from a run pipe (header pipe) to an outlet pipe, at 45 or 90 degrees, alternatively to connections made with buttweld tees, reinforcing pads and saddles. This type of forged fittings are otherwise called “branch connections”, or “branch fittings”, or “pipe branch outlet fittings” or, simply, “Olets”.

Outlet fittings are forged products with high strength and clear cost advantages over conventional pipe branching techniques.

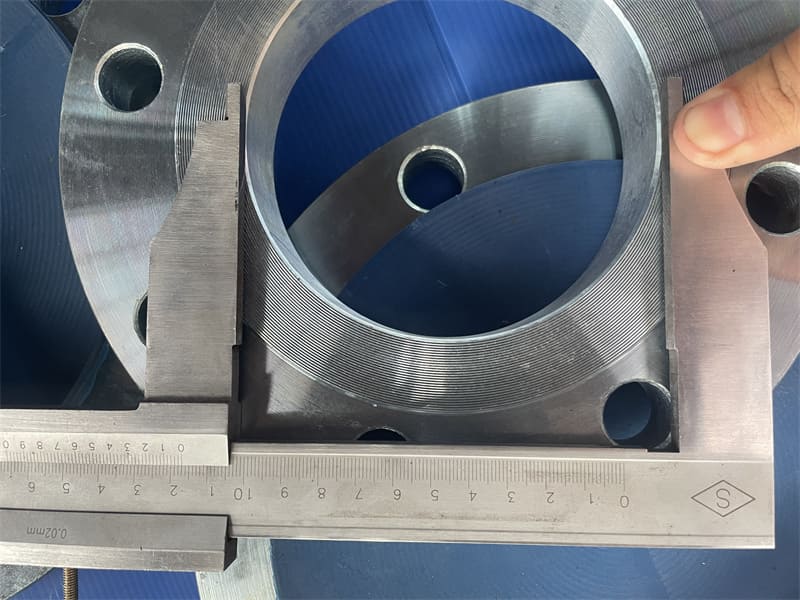

How are they installed? Quite easily: on one side, the fittings (example a Weldolet) is fixed onto the run pipe with a full penetration groove weld and, on the other side, welded (or screwed) on the branch pipe. Of course, the header pipe shall be properly cut in the proximity of the area where the pipe needs to be branched.

Weldolet Drawing and Specification