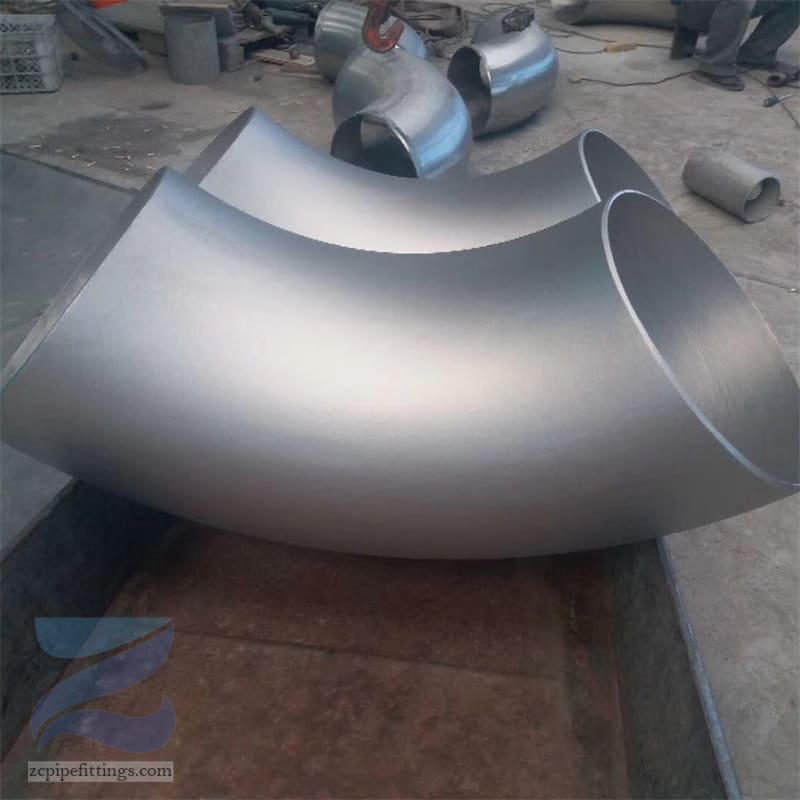

The ways to connect with the pipe are: direct welding (the most commonly used way) flange connection, hot-melt connection, electric fusion connection, thread connection and socket connection, etc. The components contained in the elbow need to be treated again on the surface. The inner and outer layers of the oxidized elbow are evenly coated with anti-rust paint through the spraying process, which is convenient for product transportation and export to foreign markets, so that the elbow products can reduce wear and tear, which is a very important process.

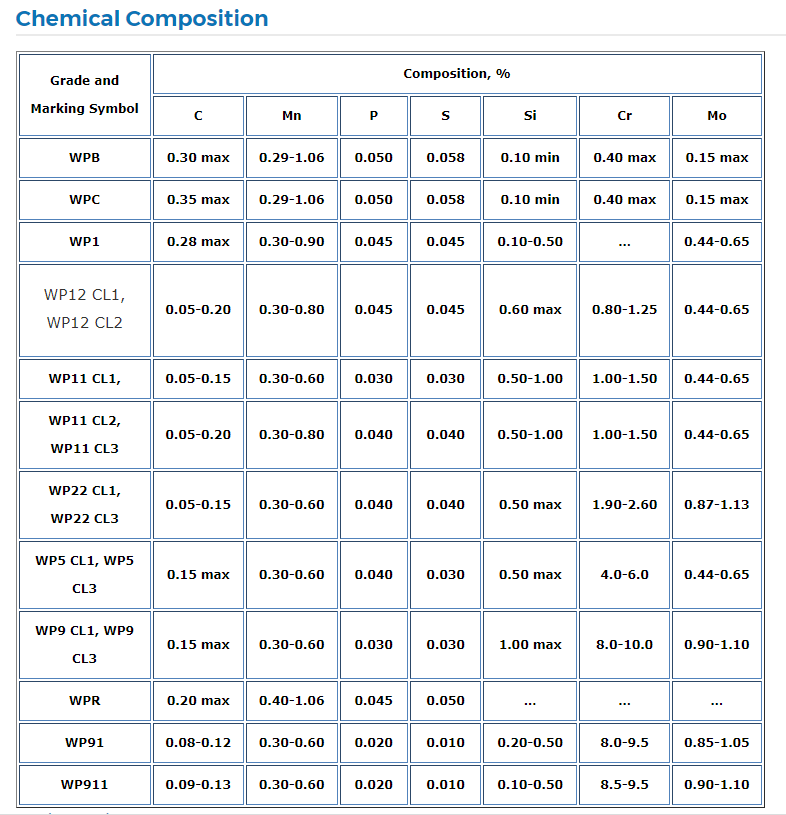

Carbon steel A234

Inspection services

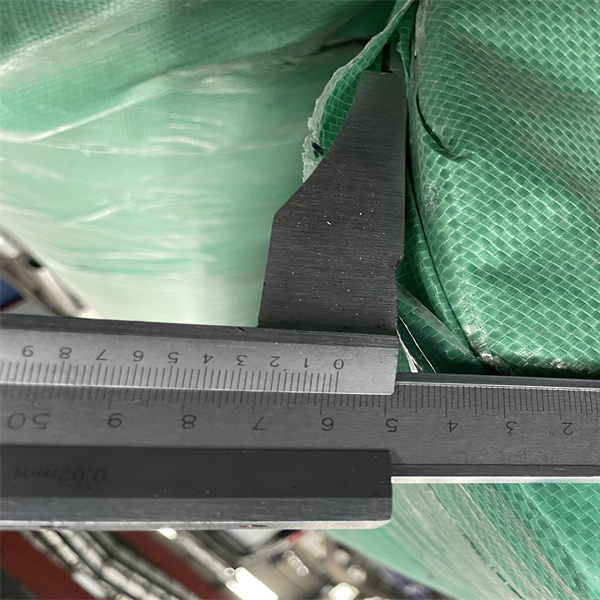

-1) check the steel pipe & fittings of outer diameter, thickness, quantity, material, etc.

-2)record it in words and photos.

-3)take video of doing PMI on the pipes & fittings & flange in material of alloy steel and stainless steel.

Packaging services

-1) classify items, count qty;

-2)prepare suitable cartons for different items, ;

-3)sst or customized ones, entering into carton after PVC packing,

-4)Mark Names/numbers/QTY/extra info outside of cartons after items collected;

-5)Mark Names/numbers/QTY/extra info outside of wooden box after cartons collected;

-6)Make packing list indicating detailed info of items(cartons/wooden box NO. and qty)

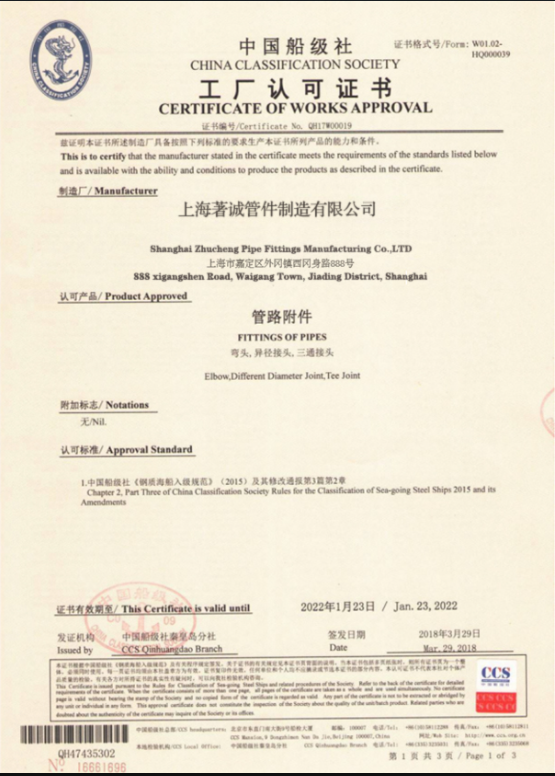

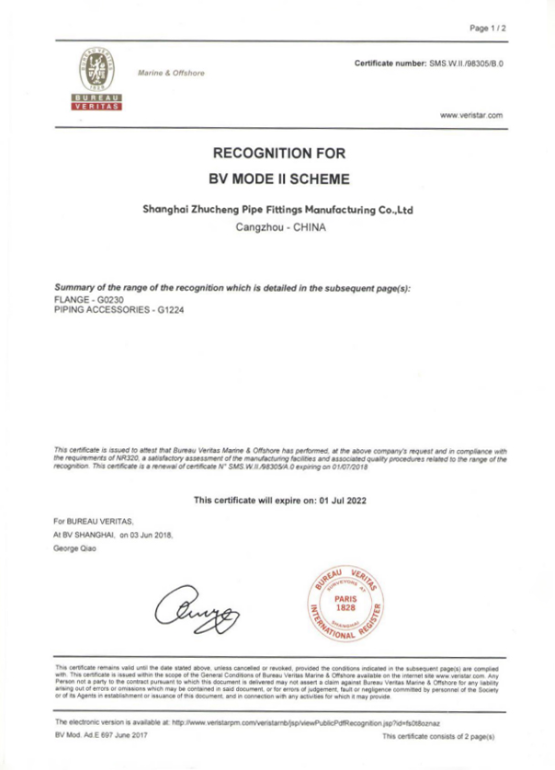

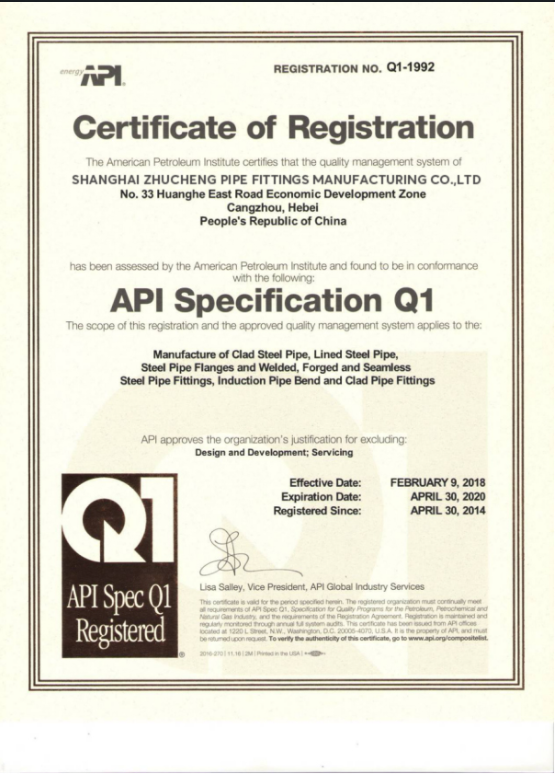

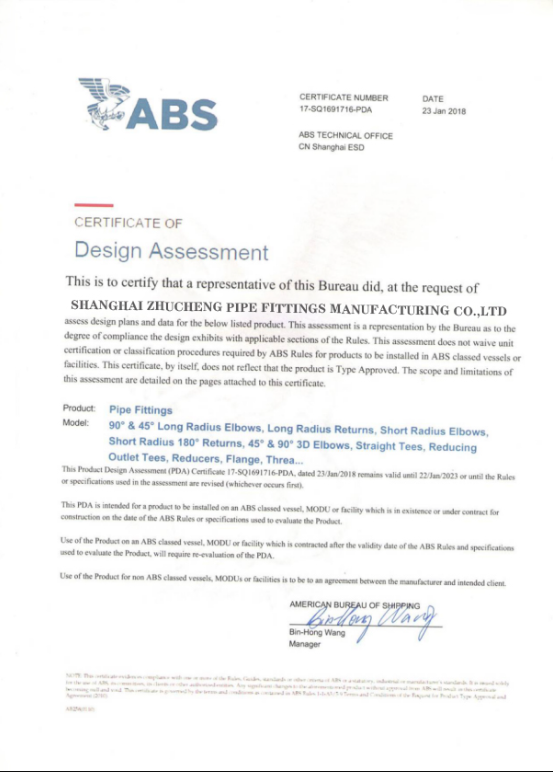

Certifications

About Us

Shanghai ZhuCheng pipe fitings company is one enterprise specialized in processing of Mss sp 43 carbon steel A234 wpb buttweld fittings manufacturer. The company is located in Shanghai, Chinese international economic, financial, trade and shipping center.

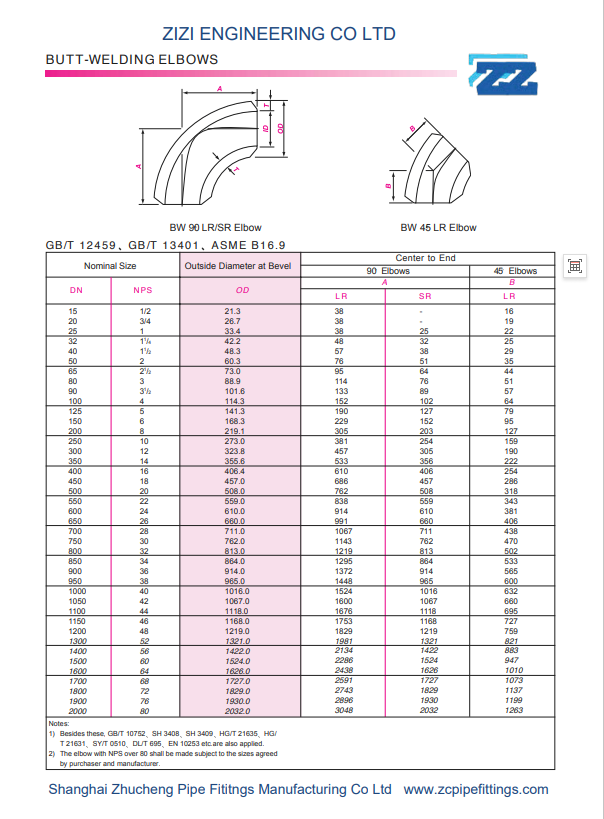

We have hundreds of sets of advanced production, processing and inspection equipment with corresponding quality system certifications. The main products include seamless pipes, welded pipes, butt welded pipe fittings, high pressure forged pipe fittings and flanges. It can be produced exactly as standard GB/T, American standard ANSI/ASME, Japanese standard JIS, Ministry of Chemical Industry HG/T, petroleum SY/T, German standard DIN, European standard CE and other standards. Customized parts can also be processed according to drawings to meet different requirements from projects.