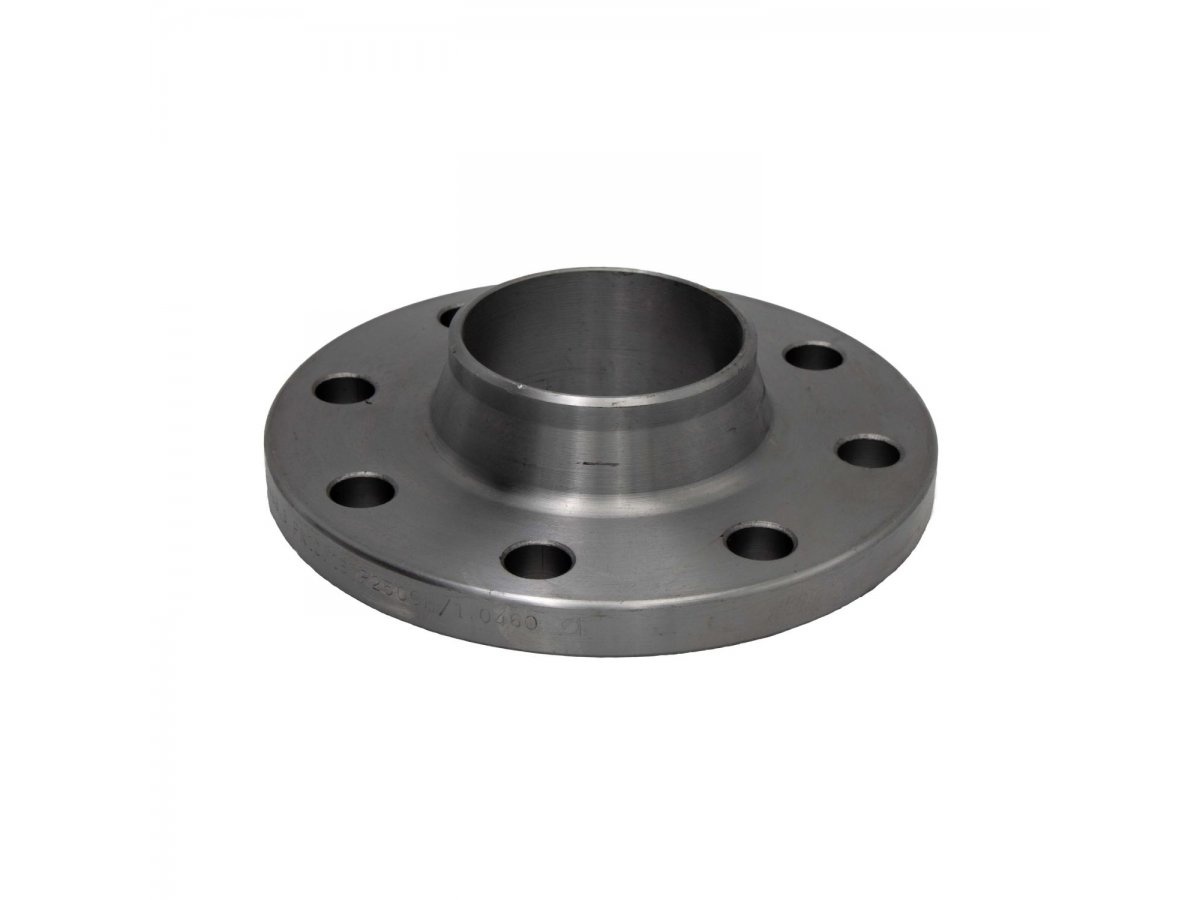

Monel 400 Material

Monel 400 is a nickel-copper alloy, mainly composed of nickel (about 63%) and copper (about 28-34%), and also contains small amounts of iron, manganese, carbon and silicon. This alloy is widely used in various industrial fields due to its excellent corrosion resistance and mechanical properties.

Monel 400 is a high-performance nickel-copper alloy with excellent corrosion resistance, mechanical properties and thermal properties. It is widely used in marine engineering, chemical equipment, oil and gas, aerospace and electronic and electrical fields. Its good processing and welding properties make it an ideal material choice for many harsh environments.

Features of Monel 400 Material

Monel 400 is a single-phase solid solution alloy with excellent corrosion resistance. It can resist erosion in many corrosive environments in the temperature range from sub-zero to 426°C.

UNS N04400 Nickel-Copper Alloy is mainly composed of nickel (Ni) and copper (Cu), and also contains a small amount of iron (Fe), manganese (Mn), carbon (C), silicon (Si) and sulfur (S). Its chemical composition ratio is roughly 63% to 68% nickel, 28% to 34% copper, 2.5% iron, 2.0% manganese, 0.3% carbon, 0.5% silicon, and 0.024% sulfur. This unique chemical composition design enables Monel 400 alloy to exhibit excellent corrosion resistance in a variety of media.

Chemical composition

| CHEMICAL | LIMITS | Ni | Cu | Fe | Mn | C | Si | S |

| Monel 400 | MIN | 63.00 | 28.00 | |||||

| MAX | 34.00 | 2.50 | 2.00 | 0.30 | 0.50 | 0.024 |

Monel 400 alloy has a high melting point of about 1300-1350°C and has high stability. The density is about 8.44-8.80g/cm³, and the thermal conductivity is 21.8 W/m-K. It has good thermal conductivity and is conducive to stable operation at different temperatures. Monel 400 alloy has excellent mechanical properties, including high strength, good impact toughness and elongation. Its tensile strength and yield strength vary in different shapes (such as rods, plates, seamless pipes, etc.), but generally remain at a high level. For example, at room temperature, the tensile strength of the rod can reach 480-760MPa, the yield strength can reach 170-585MPa, and the elongation can reach 50%-5%. These characteristics make Monel 400 alloy remain stable under complex stress conditions and not prone to breakage or deformation.

Mechanical properties

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| Monel 400 | 483 min | 172 min | 35 min |

Applications of Monel 400 Material

Hydrocarbon and chemical processing equipment

Marine engineering

Crude oil distillers

Fresh water and gasoline tanks

Boiler feed water and water heaters for similar heat exchangers

Pumps, valves, fittings, shafts and fasteners