ISO ASME B16.11 Socked Weld Elbow

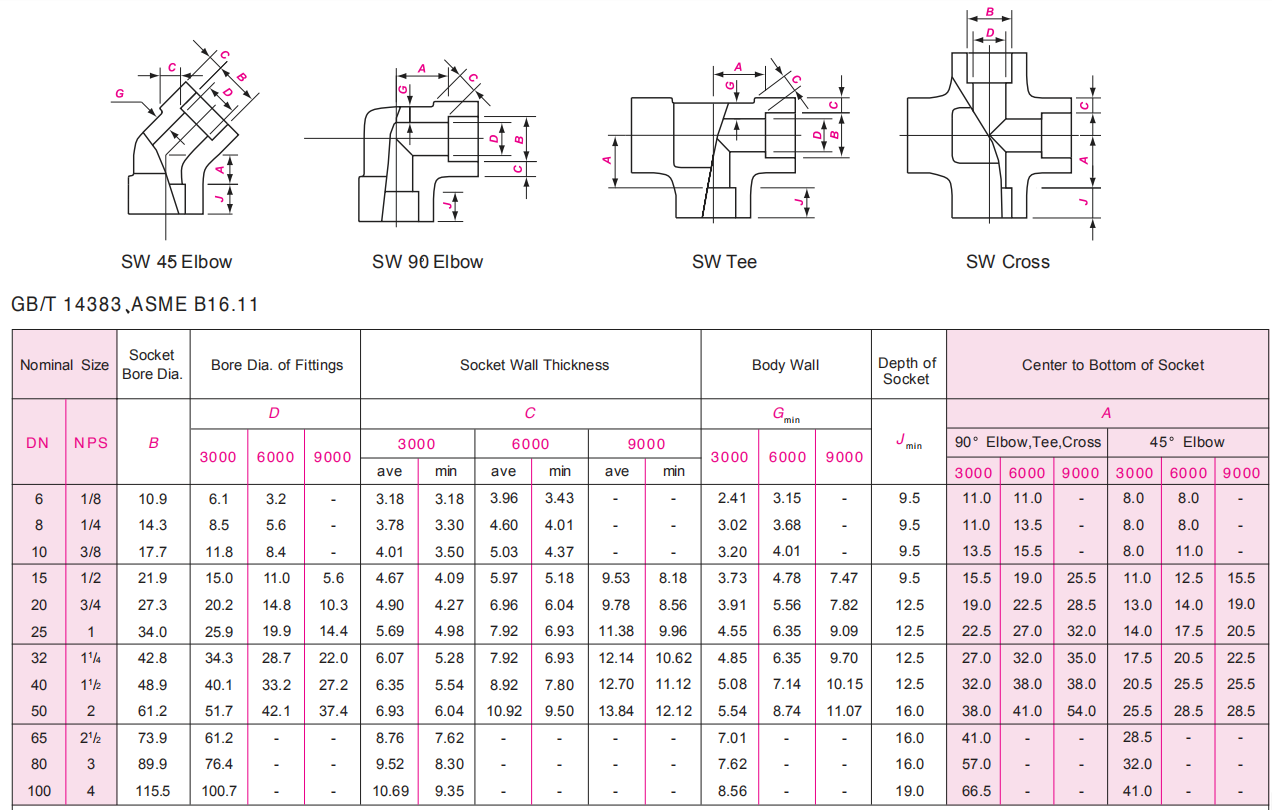

ASME B16.11 is the standard contains ratings, dimensions, tolerances, marking and material requirements for forged fittings, both socket-welding and threaded. Threaded fittings are available in pressure ratings Class 2000, 3000, and 6000; Socket welding fittings are available in pressure ratings Class 3000, 6000, and 9000.

We are the ISO approved manufacturer of steel pipe fittings. ASME B16.11 is the standard of forged steel pipe fittings which contains Socked Weld Elbow.

ASME B16.11 is the standard contains ratings, dimensions, tolerances, marking and material requirements for forged fittings, both socket-welding and threaded. Threaded fittings are available in pressure ratings Class 2000, 3000, and 6000;

Socket welding fittings are available in pressure ratings Class 3000, 6000, and 9000.

Generally, both fittings size range is 1/8″- 4″or DN6-DN100.

There are various types of ASME B16.11 socket-welding fittings, such as Elbow, Cross, Tee, Coupling, Half Coupling, Boss, Cap, Union and Sockolet; while ASME B16.11 threaded fittings can be furnished in product forms of Elbow, Cross, Tee, Coupling, Half Coupling, Boss, Cap, plug and bushing.

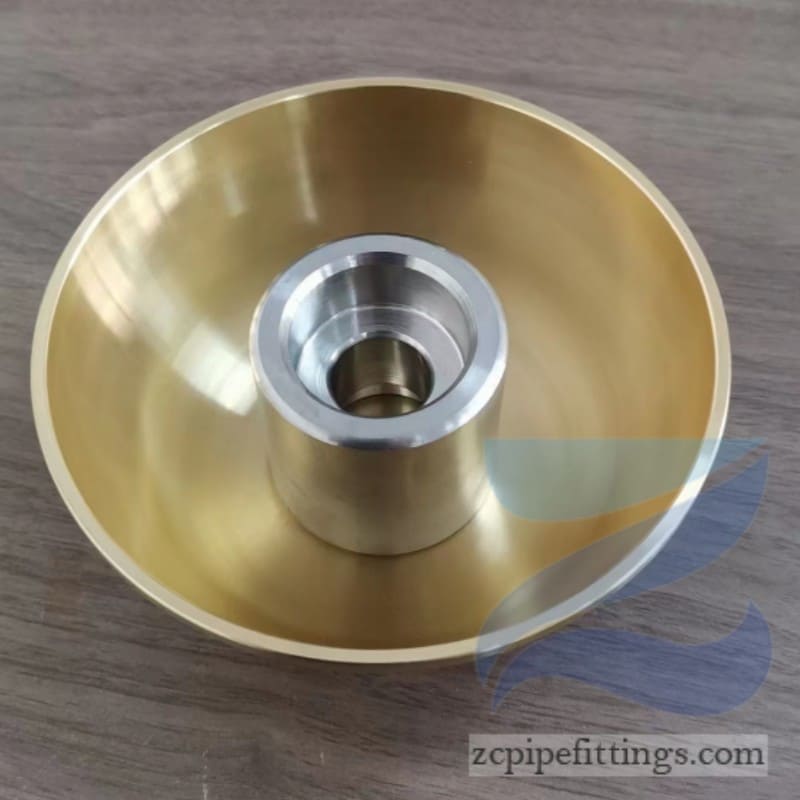

A Socket Weld Fittings is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. Once correctly inserted, fillet type sealing welds are applied to join the pipe to the fitting.

Different from buttweld fittings, Socket Weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally, for piping whose nominal diameter is NPS 2 or smaller.

These fittings are commonly called SW pipe fittings that include elbows, tees, cross, caps, coupling and union.

Socket welds can be used to change the direction of travel for pipe networks as well as join pipes at different angles and of different diameters.

The function of elbow is to change direction or flow in a piping system. There are the 45°, 90° and 180° elbows

Elbow is a pipe fitting that changes the direction of piping. According to the Angle, there are 45° and 90°180° three most commonly used. Elbow material can be divided into carbon steel, alloy steel and stainless-steel.

According to the production method, it can be divided into pushing, pressing, forging, casting, etc.

According to its radius of curvature, there are long radius elbow and short radius elbow. Long radius elbow refers to its radius of curvature is equal to 1.5 times the outside diameter of the pipe, that is, R=1.5D; A short radius elbow means that its radius of curvature is equal to the outer diameter of the pipe, that is, R= 1.0d.(D is the diameter of the elbow, and R is the radius of curvature).

| Socket Weld Fittings Specification | |

| Shape | Elbow, Tee, Cross, Coupling, Union, Cap, Reducing Insert, Sockolet |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 3000lbs, 6000lbs, 9000lbs |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Socket Weld Elbow Dimensions Drawing

Application of Forged steel fittings

Oil and Gas

Chemical

Water Pipeline

Noncritical Applications

Power station

Fire Protection