Inconel 601 Pipe

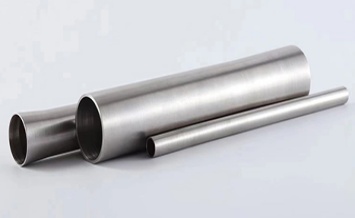

Inconel 601 pipe is a pipe made based on Inconel 601 alloy, which is a nickel-chromium-iron alloy with aluminum added to enhance its high temperature performance.

Inconel 601 pipe is a pipe made based on Inconel 601 alloy, which is a nickel-chromium-iron alloy with aluminum added to enhance its high temperature performance.

Inconel 601 is a nickel-chromium alloy used for applications that require resistance to corrosion and heat. This nickel alloy stands out due to its resistance to high temperature oxidation, remaining highly resistant to oxidation through 2200° F. Alloy 601 develops a tightly adherent oxide scale which resists spalling even under conditions of severe thermal cycling.

Inconel 601 Pipe Specification

| Grade | Inconel 601 | UNS N06601 |

|

Standard |

ASTM B167 / ASME SB167 |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Size | 15 NB to 150 NB IN |

| Form | Round, Square, Rectangular, Hydraulic Etc. |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded. |

Material analysis of Inconel 601 Pipe

Inconel 601 Pipes Chemical Composition

| Grade | C | Mn | Si |

S |

Cu | Fe | Ni | Cr |

| Inconel 601 | 0.10 max | 1.5max | 0.50 max | 0.015max | 0.50 max | remainderB | 58.0-63.0 min | 21.0-25.0 |

B : Element shall be determined arithmetically by difference.

Nickel (Ni): Nickel is the main element for forming and stabilizing austenite structure, giving the alloy good toughness, corrosion resistance and high temperature performance.

Chromium (Cr): Chromium can form a dense chromium oxide protective film on the surface of the alloy, improving the oxidation resistance and corrosion resistance of the alloy.

Iron (Fe): It is an important component of the alloy and helps to adjust the strength and processing properties of the alloy.

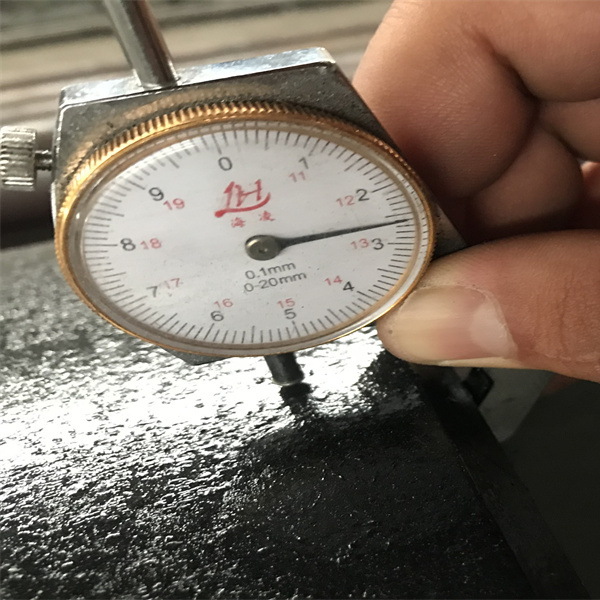

ASTM B167 Inconel 601 Seamless Pipes Mechanical Properties

| Mechanical & Physical Properties : | |

| Density | 8.1 g/cm3 |

| Melting Point | 1411 °C (2571 °F) |

| Tensile Strength | Psi – 80,000 , MPa – 550 |

| Yield Strength (0.2%Offset) | Psi – 30,000 , MPa – 205 |

| Elongation | 30% |

Tensile strength: This means that the maximum stress that the Inconel 601 pipe can withstand during the stretching process is high and it is not easy to be broken.

Yield strength: It indicates the stress value when the material begins to produce obvious plastic deformation. The higher yield strength ensures that the steel pipe will not undergo plastic deformation prematurely when subjected to a certain pressure and external force.

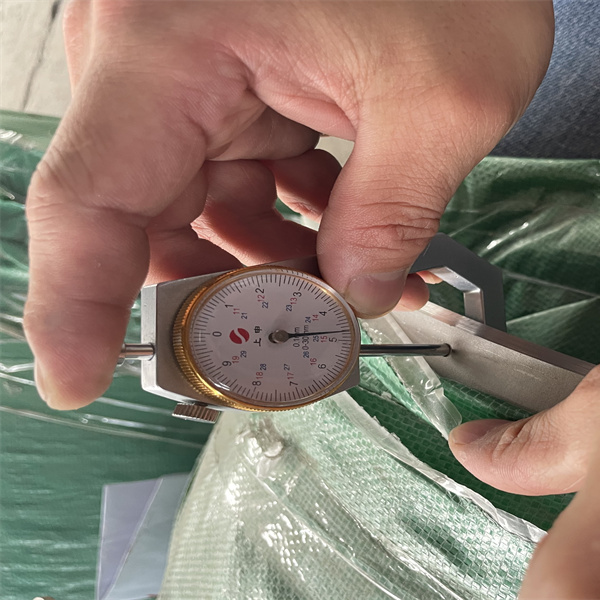

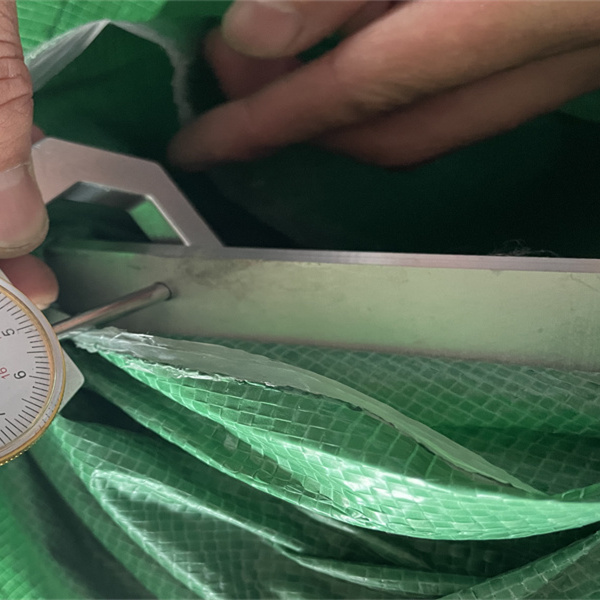

Inconel 601 Pipe Dimension

| Types | Out diameter | Wall thickness | Length |

| NB Sizes (in stock) | 1/8” ~ 8” | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Upto 6 Meters |

| inconel 601 Seamless Pipe (Custom Sizes) | 5.0mm ~ 203.2mm | As per requirement | Upto 6 Meters |

| inconel 601 Welded Pipe (in Stock + Custom Sizes) | 5.0mm ~ 1219.2mm | 1.0 ~ 15.0 mm | Upto 6 Meters |

What is Inconel 601 used for?

➪ Inconel 601 pipe can be used in a variety of applications

➪ Containment rings in gas turbines

➪ Process heaters

➪ Strippers

➪ Air preheaters

➪ Catalyst regenerators

➪ Combustion chambers in solidwaste incinerators

➪ Thermal reactors in exhaust systems of gasoline engines

➪ Grid barriers

➪ Trays for annealing / carburizing / carbonitriding / nitriding

➪ Woven-wire conveyor belts