Hastelloy C276 Flanges

C276 flange is a flange made of C276 alloy, which is also called Hastelloy C-276 and plays an important role in many fields such as chemical industry and petroleum.

C276 flange is a flange made of C276 alloy, which is also called Hastelloy C-276 and plays an important role in many fields such as chemical industry and petroleum.

The special chemical composition of C276 alloy makes it have excellent resistance to a variety of corrosive media, including oxidizing and reducing acids, chloride solutions, etc. This allows C276 flanges to be used for a long time in harsh corrosive environments, reducing maintenance and replacement costs.

C276 alloy can be welded by a variety of welding methods, such as tungsten inert gas welding (TIG), metal arc welding (MIG), etc. During the welding process, the alloy can maintain good metallurgical properties, high weld quality, and similar corrosion resistance and mechanical properties to the parent material. This provides a reliable guarantee for the connection between the flange and the pipeline, and can meet the installation requirements of different engineering sites.

Specifications Of Hastelloy C276 Flanges

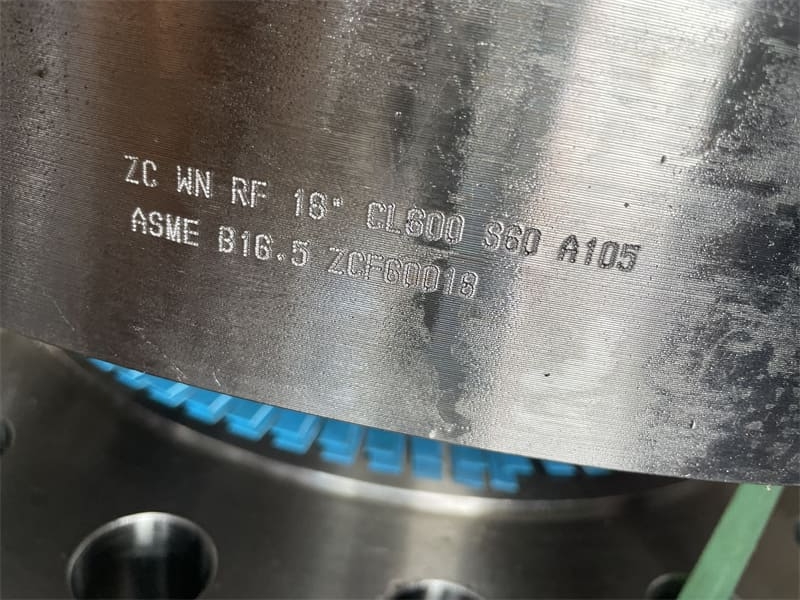

| Standards | ANSI/ASME B16.5, EN Flanges, BS 10, B16.47 Series A & B, EN-1092, ASME Flanges, BS Flanges, B16.48, DIN, DIN Flanges, GOST Flanges, ANSI Flanges, BS4504. |

| Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Production technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Ring Type Joint (RTJ), Small Tongue, Raised Face (RF), Lap-Joint Face (LJF), Small Male-Female (SMF), Flat Face (FF), Large Tongue & Groove, Large Male-Female (LMF). |

| Application | Gas, Power, Chemical, Metallurgy, Petroleum, Shipbuilding, Construction etc. |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

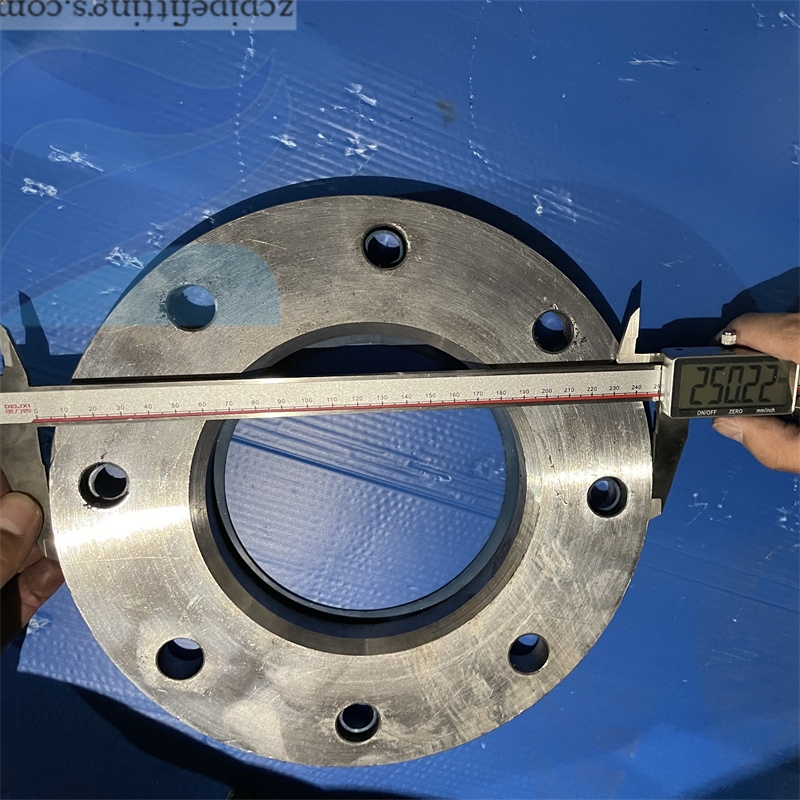

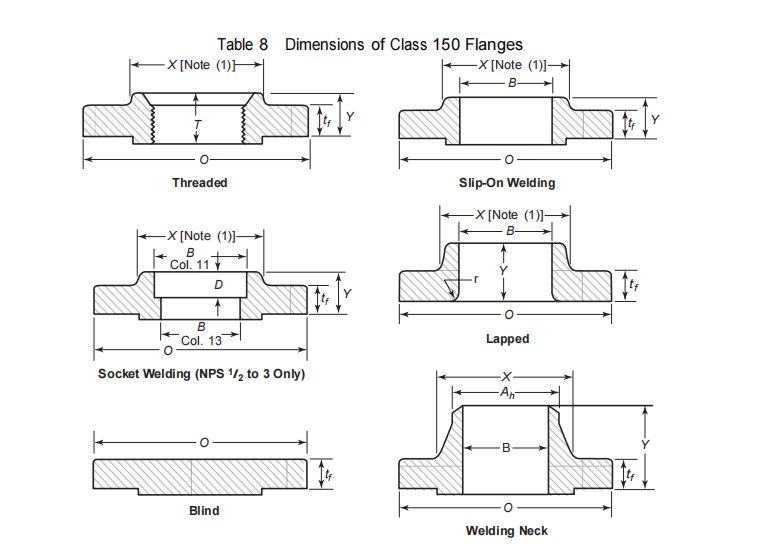

Hastelloy C276 Flanges Dimension

| Nominal Pipe

Size, NPS |

Outside

Diameter of Flange, O |

Minimum

Thickness of Flange, tf [Notes (2)-(4)] |

Minimum

Thickness Lap Joint, tf |

Diameter

of Hub, X |

Hub

Diameter Beginning of Chamfer Welding Neck, Ah [Note (5)] |

Length Through Hub | Minimum

Thread Length Threaded, T [Note (6)] |

Bore | Welding

Neck/ Socket Welding, B [Note (7)] |

Corner

Bore Radius of Lapped Flange and Pipe, r |

Depth of

Socket, D |

|||

| Threaded/

Slip-on/ Socket Welding, Y |

Lapped,

Y |

Welding

Neck, Y |

Minimum Slip-on/

Socket Welding, B |

Minimum

Lapped, B |

||||||||||

| 1/2 | 90 | 9.6 | 11.2 | 30 | 21.3 | 14 | 16 | 46 | 16 | 22.2 | 22.9 | 15.8 | 3 | 10 |

| 3/4 | 100 | 11.2 | 12.7 | 38 | 26.7 | 14 | 16 | 51 | 16 | 27.7 | 28.2 | 20.9 | 3 | 11 |

| 1 | 110 | 12.7 | 14.3 | 49 | 33.4 | 16 | 17 | 54 | 17 | 34.5 | 34.9 | 26.6 | 3 | 13 |

| 1 1/4 | 115 | 14.3 | 15.9 | 59 | 42.2 | 19 | 21 | 56 | 21 | 43.2 | 43.7 | 35.1 | 5 | 14 |

| 1 1/2 | 125 | 15.9 | 17.5 | 65 | 48.3 | 21 | 22 | 60 | 22 | 49.5 | 50.0 | 40.9 | 6 | 16 |

| 2 | 150 | 17.5 | 19.1 | 78 | 60.3 | 24 | 25 | 62 | 25 | 61.9 | 62.5 | 52.5 | 8 | 17 |

| 2 1/2 | 180 | 20.7 | 22.3 | 90 | 73.0 | 27 | 29 | 68 | 29 | 74.6 | 75.4 | 62.7 | 8 | 19 |

| 3 | 190 | 22.3 | 23.9 | 108 | 88.9 | 29 | 30 | 68 | 30 | 90.7 | 91.4 | 77.9 | 10 | 21 |

| 3 1/2 | 215 | 22.3 | 23.9 | 122 | 101.6 | 30 | 32 | 70 | 32 | 103.4 | 104.1 | 90.1 | 10 | |

| 4 | 230 | 22.3 | 23.9 | 135 | 114.3 | 32 | 33 | 75 | 33 | 116.1 | 116.8 | 102.3 | 11 | |

| 5 | 255 | 22.3 | 23.9 | 164 | 141.3 | 35 | 36 | 87 | 36 | 143.8 | 144.4 | 128.2 | 11 | |

| 6 | 280 | 23.9 | 25.4 | 192 | 168.3 | 38 | 40 | 87 | 40 | 170.7 | 171.4 | 154.1 | 13 | |

| 8 | 345 | 27.0 | 28.6 | 246 | 219.1 | 43 | 44 | 100 | 44 | 221.5 | 222.2 | 202.7 | 13 | |

| 10 | 405 | 28.6 | 30.2 | 305 | 273.0 | 48 | 49 | 100 | 49 | 276.2 | 277.4 | 254.6 | 13 | |

| 12 | 485 | 30.2 | 31.8 | 365 | 323.8 | 54 | 56 | 113 | 56 | 327.0 | 328.2 | 304.8 | 13 | |

| 14 | 535 | 33.4 | 35.0 | 400 | 355.6 | 56 | 57 | 125 | 57 | 359.2 | 360.2 | Note(8) | 13 | |

| 16 | 595 | 35.0 | 36.6 | 457 | 406.4 | 62 | 64 | 125 | 64 | 410.5 | 411.2 | Note(8) | 13 | |

| 18 | 635 | 38.1 | 39.7 | 505 | 457.0 | 67 | 68 | 138 | 68 | 461.8 | 462.3 | Note(8) | 13 | |

| 20 | 700 | 41.3 | 42.9 | 559 | 508.0 | 71 | 73 | 143 | 73 | 513.1 | 514.4 | Note(8) | 13 | |

| 24 | 815 | 46.1 | 47.7 | 663 | 610.0 | 81 | 83 | 151 | 83 | 616.0 | 616.0 | Note(8) | 13 | |

Application areas

Chemical industry:

In chemical production, many reaction processes involve highly corrosive media, and C276 flanges are widely used in the connection of various chemical equipment and pipelines.

Power industry:

In the flue gas desulfurization device of the power industry, C276 flanges are used to connect equipment such as absorption towers, pipelines and pumps. These equipment need to handle slurries containing corrosive components such as sulfur dioxide and chlorides. The corrosion resistance of C276 flanges can ensure the long-term stable operation of the system and reduce corrosion damage and maintenance costs of equipment.

Pharmaceutical industry:

In the pharmaceutical process, the production of some drugs needs to be carried out in a strictly controlled environment and will be exposed to various chemical reagents and solvents. The high corrosion resistance and good hygienic properties of C276 flanges make it suitable for the connection of pharmaceutical equipment and pipelines, ensuring that the drug production process is not contaminated and ensuring the quality of drugs.