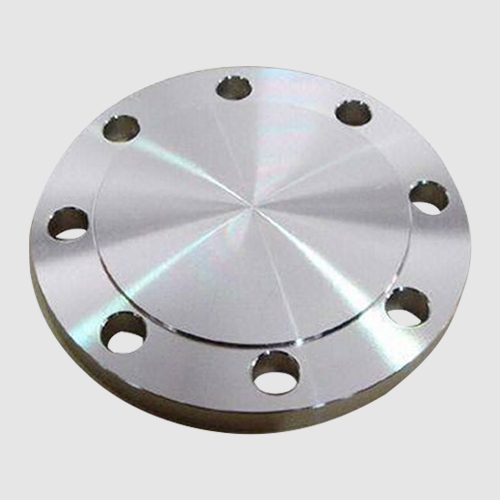

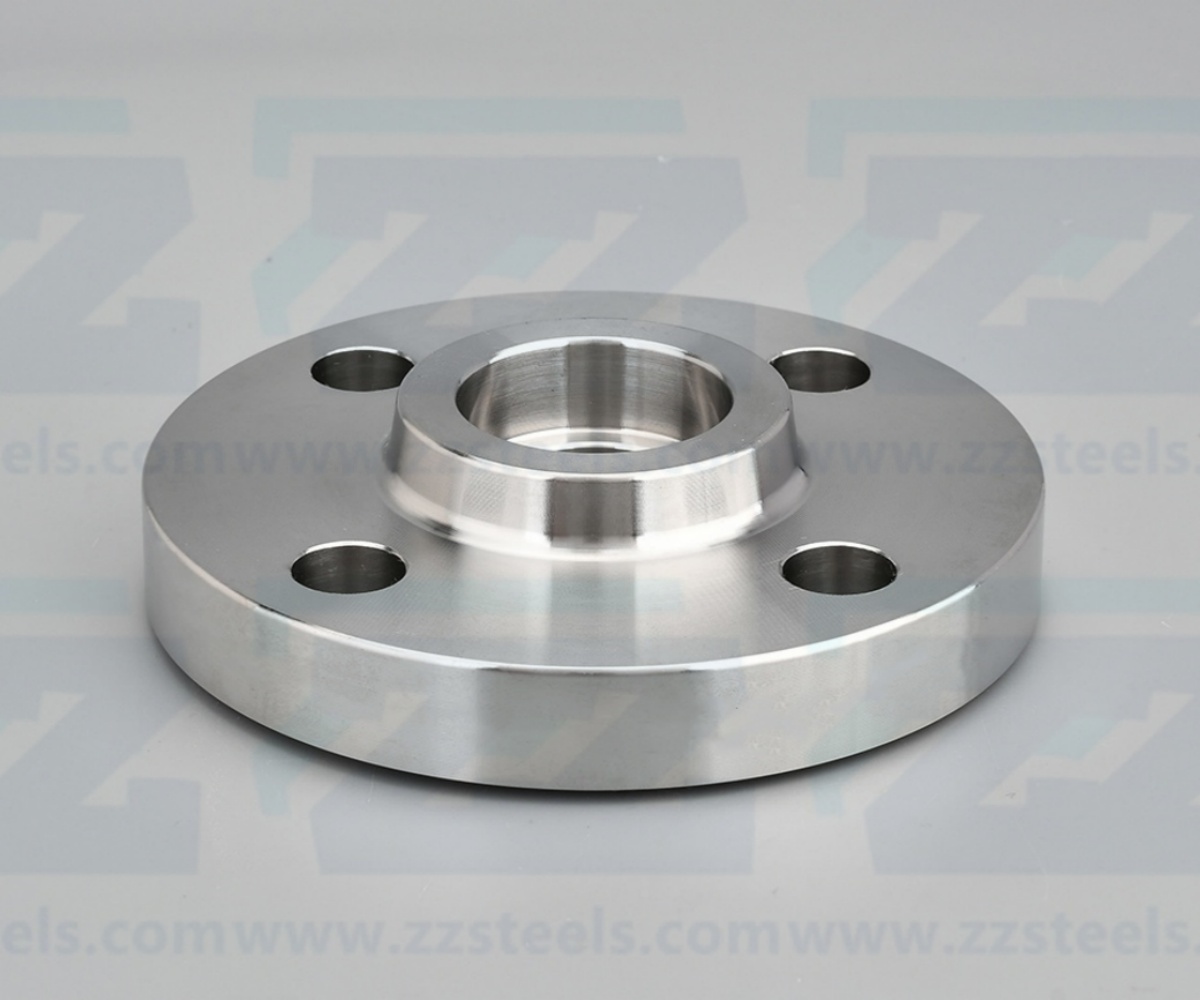

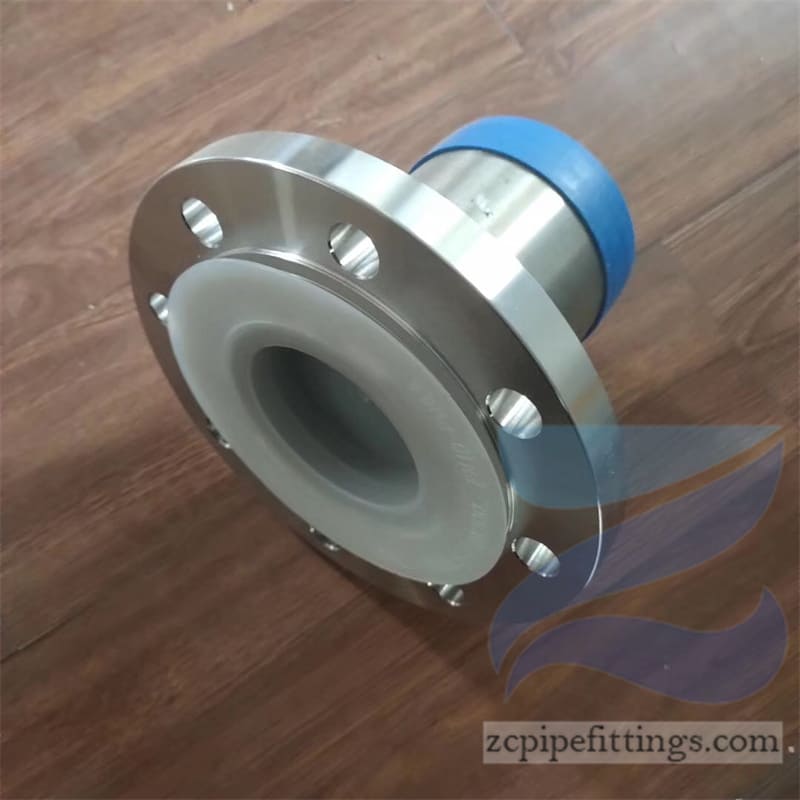

Hastelloy C22 Slip On Flange

Hastelloy C22 slip on flange is a nickel-chromium-molybdenum-tungsten alloy flange with excellent corrosion resistance. It can perform well in various harsh corrosive environments, such as environments containing strong corrosive media such as chloride ions and sulfate ions.

Hastelloy C22 slip on flange is a nickel-chromium-molybdenum-tungsten alloy flange with excellent corrosion resistance. It can perform well in various harsh corrosive environments, such as environments containing strong corrosive media such as chloride ions and sulfate ions. It has good tolerance to both oxidizing and reducing media. For example, in the strong acid solution environment in hydrometallurgy, Hastelloy C22 can effectively prevent corrosion and ensure the sealing and stability of pipeline connections.

Hastelloy C22 has good high temperature strength and oxidation resistance. In high temperature environments, it can maintain good mechanical properties. The slip on flange can withstand the pressure of the pipeline system and will not degrade due to high temperature oxidation. Slip on flanges are widely used in the connection of medium and low pressure containers and pipelines, especially in the fields of chemical industry, petrochemical industry, etc.

Hastelloy C22 Slip On Flange Specfication

| Material | Hastelloy C22 / ASTM B564 UNS N06022 |

| Technique Use In Forging | Forged, Heat treated & machined |

| Flanges Types | Plate Flange&Blind Flange |

| Size | DN10-DN1200 |

| Pressure Ratings | PN6 PN10 PN16 PN25 PN40 PN60 PN100 PN160 PN250 |

| Standards | EN1092-1 |

Material characteristics of Hastelloy C22

Chemical composition

| CHEMICAL | LIMITS | Ni | Fe | Mn | C | Si | S | Cr | Mo | P | W | Co | V |

| Hastelloy C22 | MIN | Balance | 2.00 | 20.00 | 12.50 | 2.50 | |||||||

| MAX | 6.00 | 0.50 | 0.02 | 0.08 | 0.02 | 22.50 | 14.50 | 0.02 | 3.50 | 2.50 | 0.35 |

The nickel (Ni) content is about the balance (usually above 50%). Nickel is one of the main elements in Hastelloy C22 alloy, which gives the alloy good toughness, machinability and corrosion resistance. Nickel can form a passivation film on the surface of the alloy to prevent the corrosive medium from further eroding the metal matrix. In many corrosive environments, such as acidic and alkaline solutions and media containing chloride ions, the presence of nickel helps to improve the overall corrosion resistance of the alloy.

The chromium (Cr) content is between 20 and 22.5%. Chromium is an important alloying element that forms a dense protective film of chromium oxide (Cr₂O₃) on the surface of the alloy. This protective film has good stability in an oxidizing environment and can effectively prevent further oxidation of the alloy.

The molybdenum (Mo) content is 12.5-14.5%. The addition of molybdenum significantly improves the corrosion resistance of the alloy to reducing media. In the environment of reducing acids such as hydrochloric acid and sulfuric acid, molybdenum can react with the corrosive medium to form a stable protective film to prevent further corrosion of the metal by the acid. In addition, molybdenum can also improve the strength and hardness of the alloy, which helps to enhance the structural stability of Hastelloy C22 slip on flanges when subjected to pressure.

The tungsten (W) content is about 2.5 – 3.5%. Tungsten helps to improve the high temperature strength and corrosion resistance of the alloy. In high temperature environments, tungsten can inhibit grain growth, thereby maintaining the microstructural stability of the alloy. This allows Hastelloy C22 slip on flanges to withstand higher pressures and corrosion in high temperature chemical processes or other high temperature application scenarios without easily deforming or corroding.

Mechanical Property

| MATERIAL | T.S (MPA) | Y.S (MPA) | EL % |

| Hastelloy C22 | 690 min | 276 min | 30 min |

Application fields of Hastelloy C22 slip on flange

Chemical industryIn chemical production, various acidic media are often involved, such as hydrochloric acid, sulfuric acid, etc. Hastelloy C22 flange can work stably in these strong acidic environments due to its excellent corrosion resistance.

Petroleum and natural gas industry

During the oil well mining process, the downhole environment is complex and contains a variety of corrosive media, such as hydrogen sulfide, carbon dioxide, etc. Hastelloy C22 flange can be used for the connection of wellhead equipment, such as the connection between the Christmas tree and the oil pipeline. Its good corrosion resistance and mechanical properties can ensure the sealing and reliability of the flange connection under harsh downhole environment and high pressure conditions to prevent oil and gas leakage.

Marine engineering

Offshore oil platforms are in the marine environment and are threatened by various corrosion factors such as seawater, salt spray, and humid air. Hastelloy C22 slip on flanges are used for the connection of pipelines such as oil and gas processing equipment, water injection systems, and fire protection systems on the platform. Its excellent corrosion resistance and good mechanical properties can adapt to the harsh environmental conditions at sea and ensure the safe operation of oil platforms.