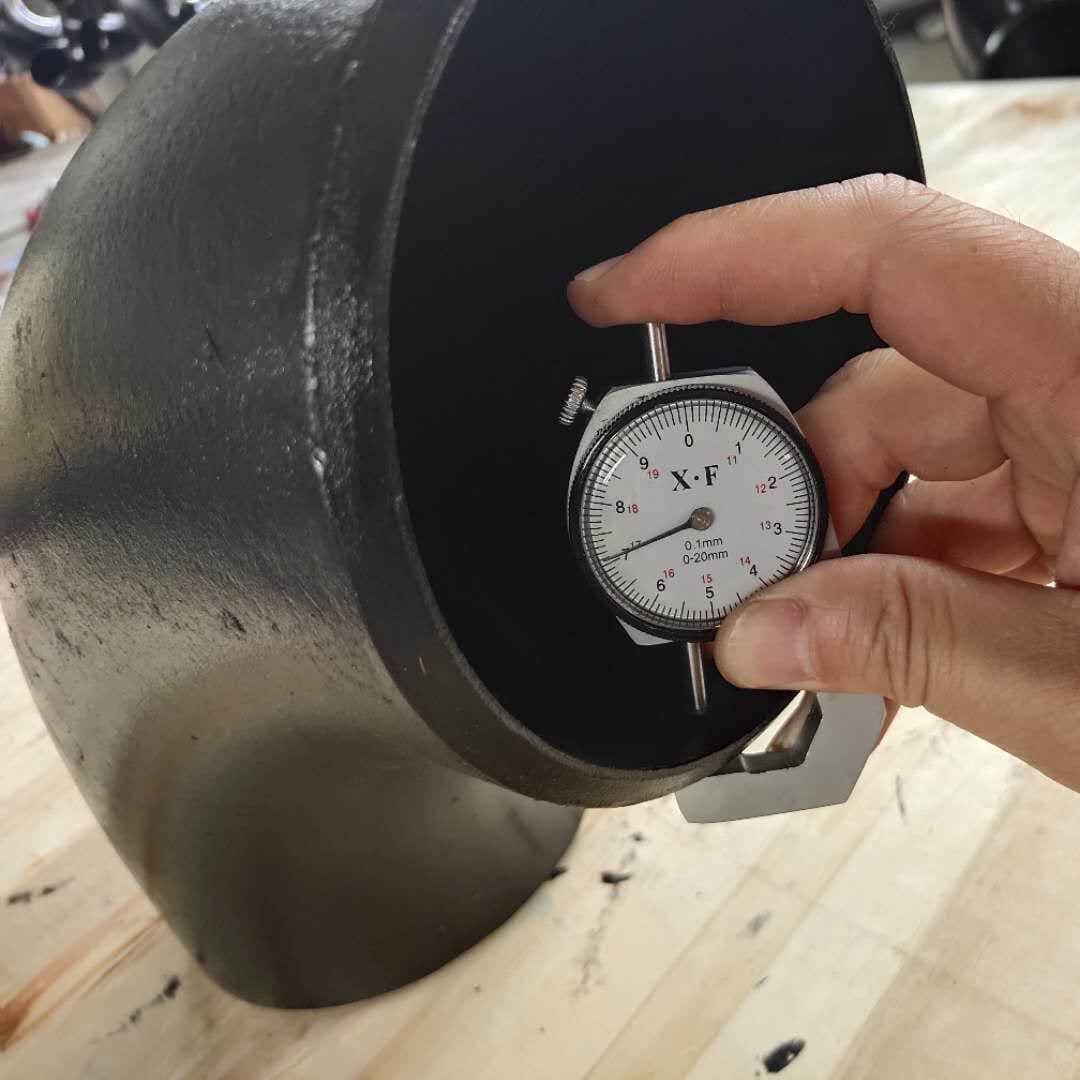

8IN SCH40 90 Degree Long Redius Butt Weld Steel Elbow

The function of a 45 Degree Long Radius Elbow is same as 90 degrees long and short elbow, but the measurement and dimensions are different to that of a 90 degree long and the short elbow.

Why choose us?

We have hundreds of advanced production facility and inspection equipment, and have certified by quality management system.The steel pipe fittings and flanges are produced according to National Standard GB / T, American Standard ANSI / ASME, Japanese Standard JIS, Ministry of Chemical Industry Hg / T, Petroleum SY / T, German Standard DIN, and European Standard CE. We can also fabricate as per drawing. ASTM A234WPB 12IN SCHSTD 45Deg Elbow is one of our main product. We are persuing in providing high-quality products, technical support and good after-sales service for customers.Hope to have good cooperation with every potential customers.

Production Description

ASTM A234WPB 12IN SCHSTD 45Deg Elbow is second common use after 90 degree elbow. The function of a Carbon steel 45 degree elbowis the same as a 90 degree elbow, but the measurement of dimensions is different to that of the 90 degree elbow.Compared to 90 degree elbow, 45 degree elbow produces less friction, and with the lower pressure. 45 degree elbow is widely used in chemical industry, food, water supply facilities, electronic industry, chemical pipeline, horticulture, agricultural production, solar equipment pipeline, air conditioning pipeline and other fields.

Production Advantages

Easy to transport and handle

high strength

less resistance

Corrosion resistance

easy to install

economy

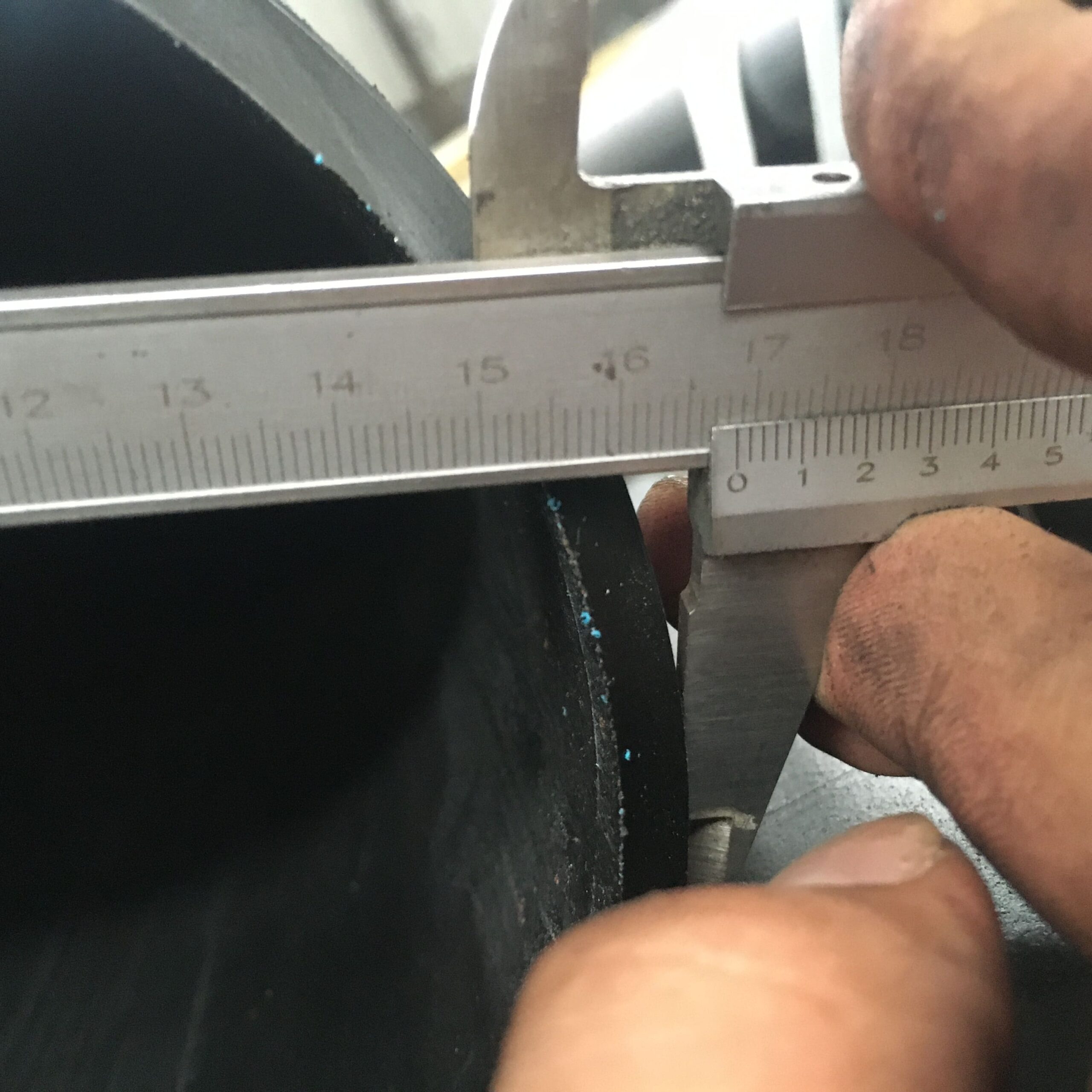

Specificaton of ASTM A234WPB 12IN SCHSTD 45Deg Elbow

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

90 Degree Elbow Dimensions and Weight Chart