Eccentric Reducer Stainless Pipe Fittings

BW reducers can be concentric (COC) reducer and eccentric (ECC) reducer.These reducers have same functions,the only difference is the internal structure.Stainless pipe fittings are popular because of the an-ti corrosive function.Stainless steel pipe fittings can used over 50 years.

Reducer is a common used butt welded fitting.

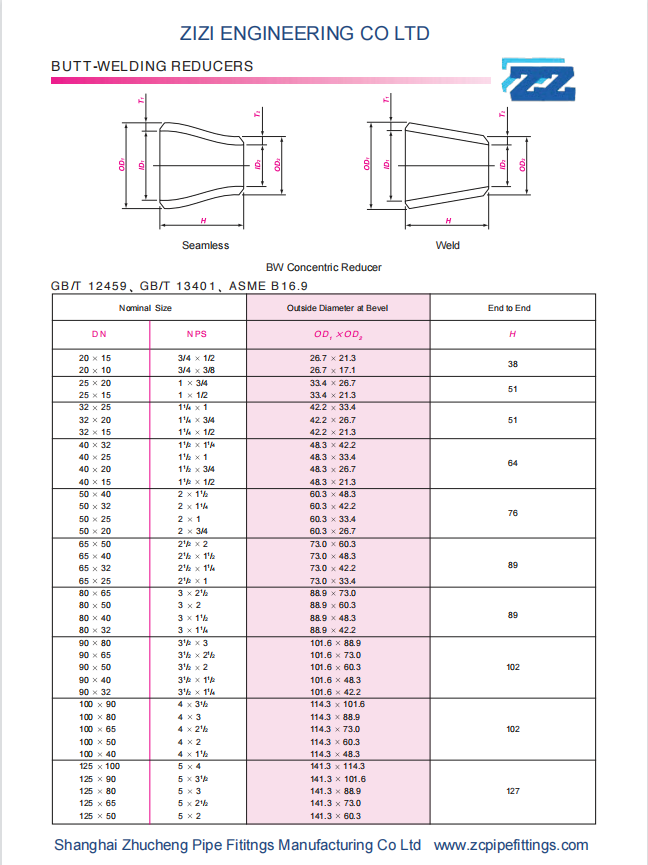

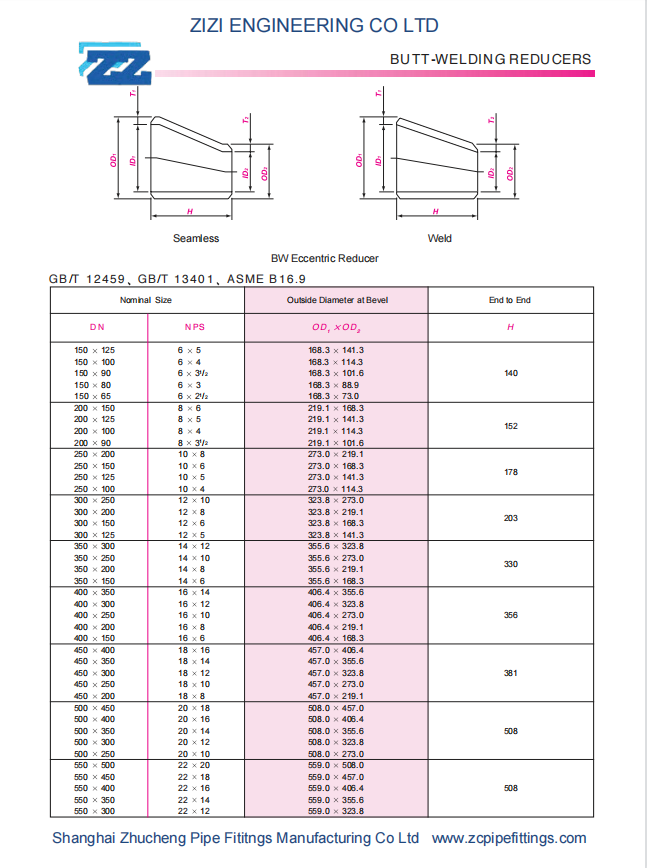

BW reducer has two types:Concentric Reducer and Eccentric Reducer.

The two ends of concentric reducer are designed with large diameter and small diameter, and the pipe is connected through conical transition section on the same axis.

Eccentric reducers have different end sizes and are used to connect pipes with different diameters on the same axis.

Stainless pipe fittings are created for high temperature/perssure and corrosive environments.It has has superior performance especially in the corrosive environment,design life over 50 years.

Product features

- This type of reducer helps to connect big pipes with small pipes.

- These reducers decrease noise and vibration.

- It requires minimum setting up space.

- It also absorbs noise which is created by pipe wall and fluid tolerated.

- It has minimum turbulence entrapment.

- This type of reducer is utilized with the flat side up in pump pressure to minimize cavitation.

ECC Reducer VS COC Reducer

- The joint effect of the two is that the diameter change needs to change from one specification to another.

- Concentric reducer is conducive to fluid flow, and the interference to fluid flow state is small when the diameter is reduced. Therefore, concentric reducers are used for gas and vertical flow liquid pipelines;

- One side of the eccentric reducer is flat, which is convenient for exhaust or liquid discharge, startup and maintenance. Therefore, eccentric reducer is generally used for horizontal liquid pipeline.

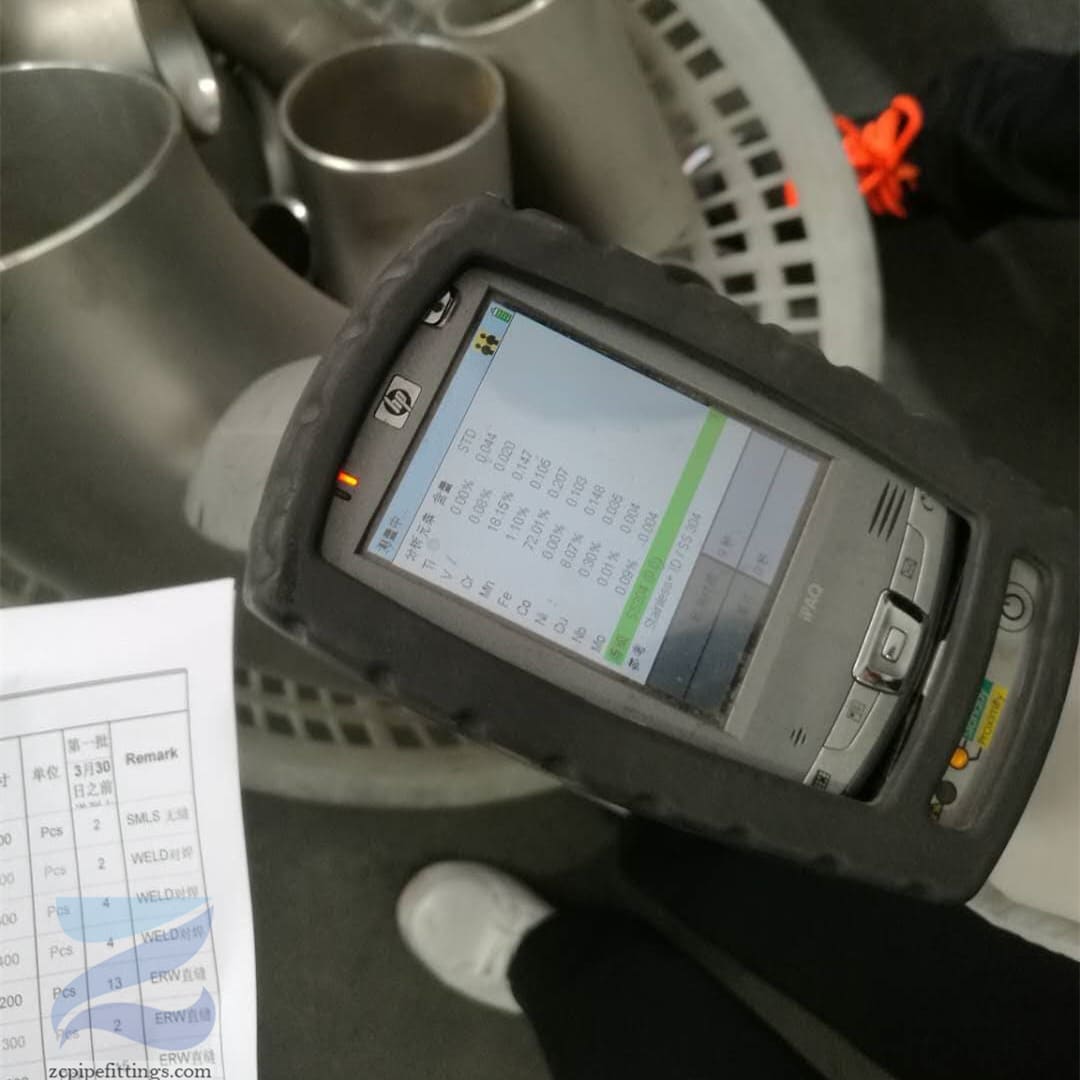

The end of Butt welded fittings are connected to the pipe system by butt welding.Butt weld fittings provide permanent leak-proof performance.BW fittings could made from seamless or welded pipe,and then through several processes formed to get the shape of pipe fittings.

Applications

- Eccentric reducers are frequently used to avoid trapping air within the system, so they are often used when both air and liquids may be flowing together.

- Eccentric reducers are used when the pipes have to maintain the same top or bottom level.

- Eccentric reducers are often used to avoid air retention in the system, so they are usually used when air and liquid may flow at the same time.

SPECIFICATION

| Shape | Reducer |

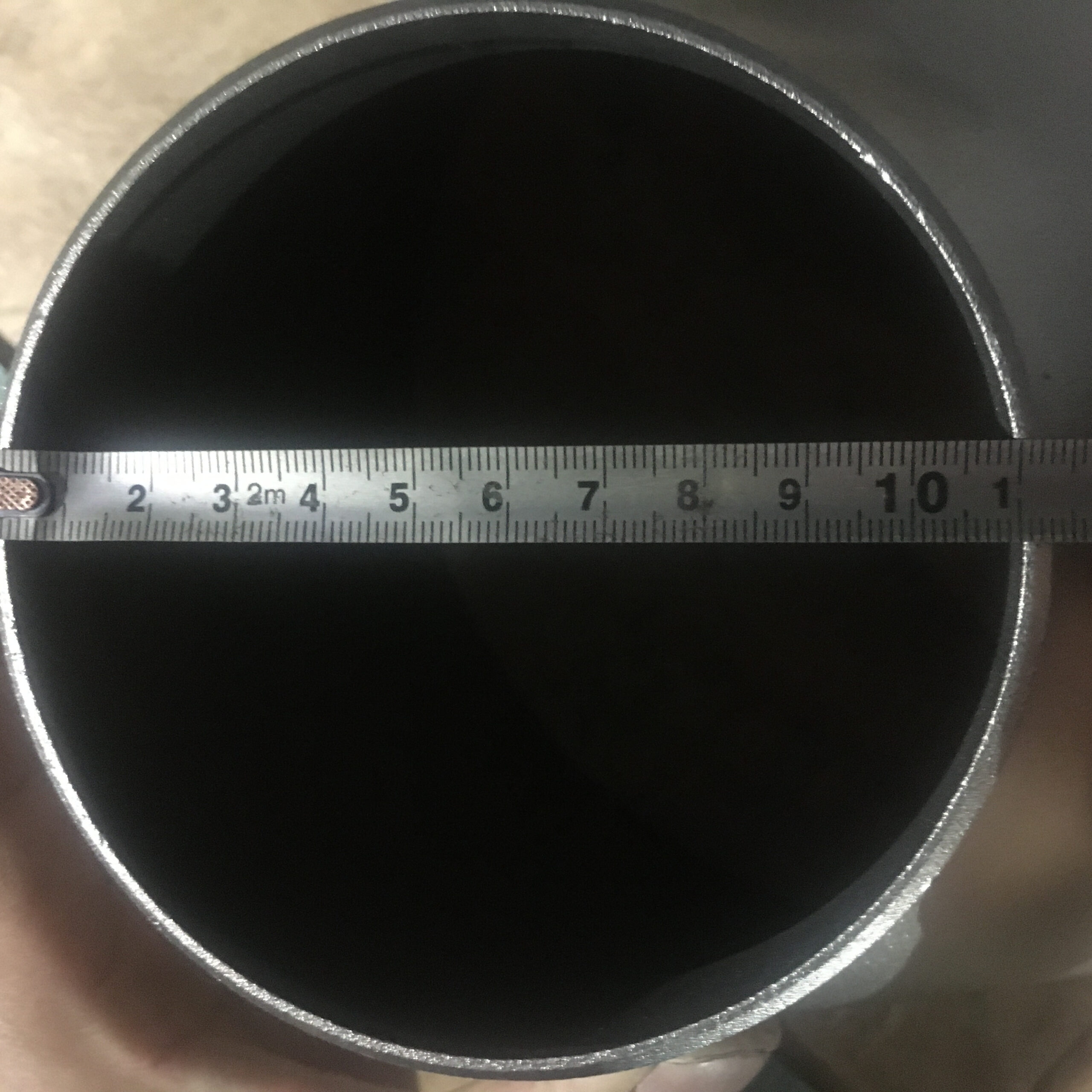

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |