Concept of slip on welding flange

Slip on welding flanges contains plate flat welding flanges and necked flat welding flanges.

Plate SO welding flange is suitable for steel pipe connection with nominal pressure not exceeding 2.5MPa. The sealing surface of the flat welding flange can be made into three types: smooth type, concave-convex type and tongue-and-groove type. The application of smooth flat welding flange is the largest.

The neck SO welding flange with neck is lower, which improves the rigidity and bearing capacity of the flange. Compared with butt welding flanges, the welding workload is large, the consumption of welding rods is high, and it cannot withstand high temperature and high pressure, repeated bending and temperature fluctuations, but it is more convenient to install on site, and the process of slapping and rubbing the welding seam can be omitted, which is more popular.

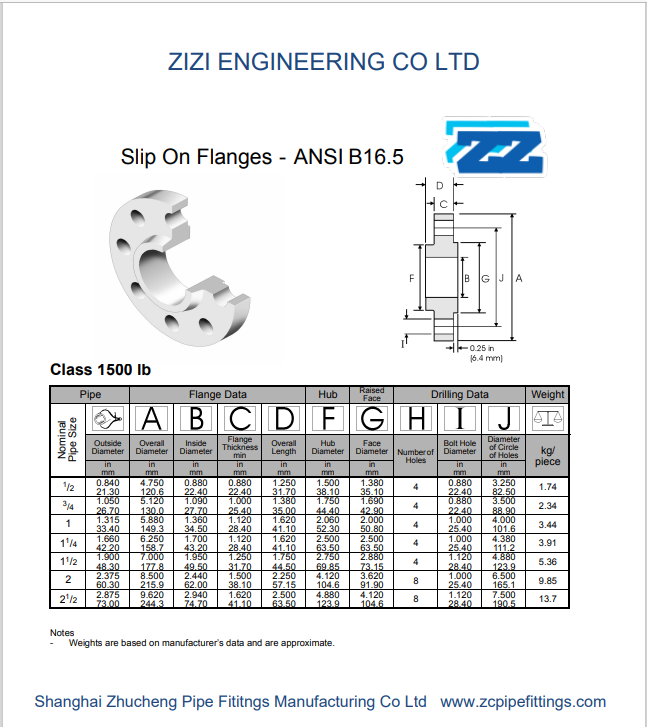

Specifications

| ealing Face | RF, FF, FTJ |

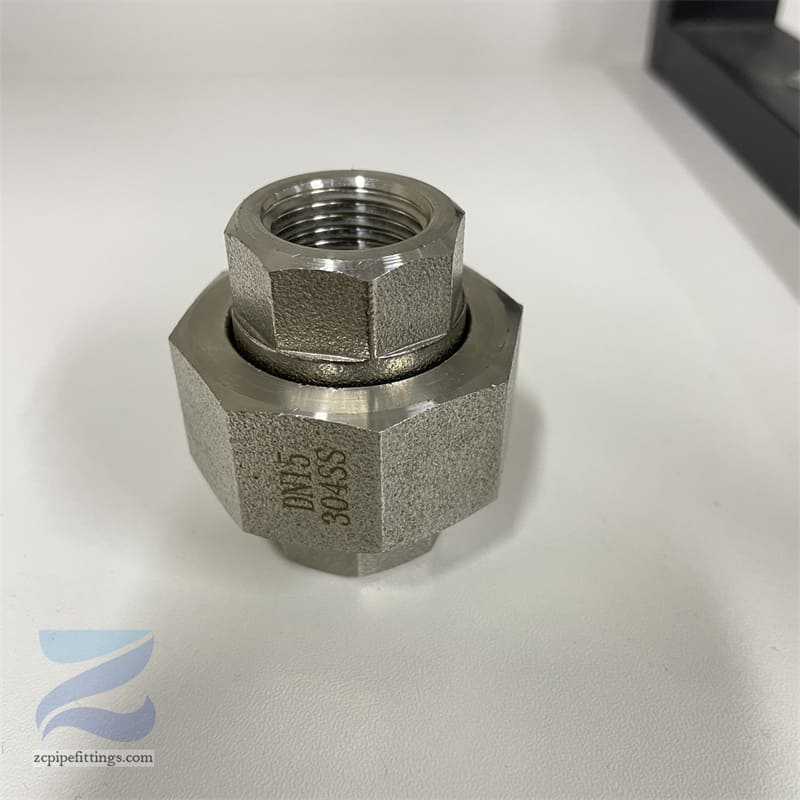

| Size Range | 1/2″ – 24″ / DN15 – DN600 |

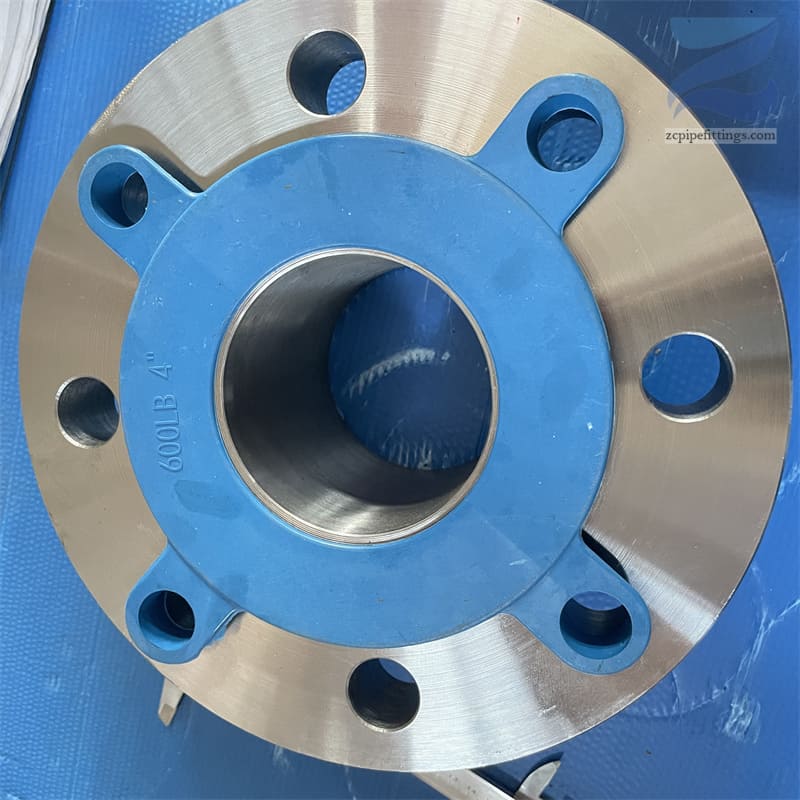

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ANSI / ASME B16.5, EN1092-1 |

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2 / LF3 |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |