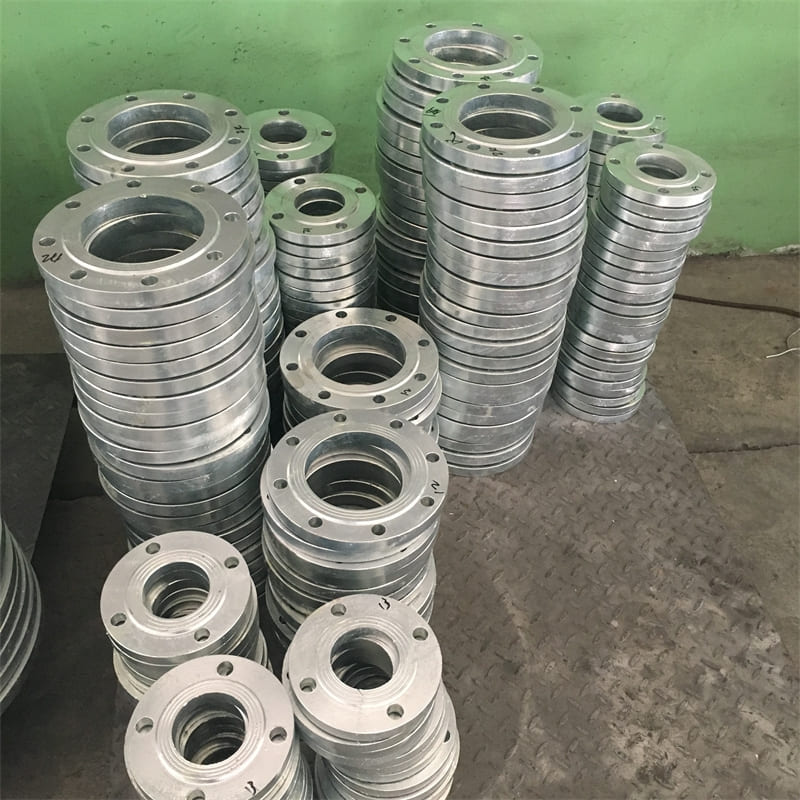

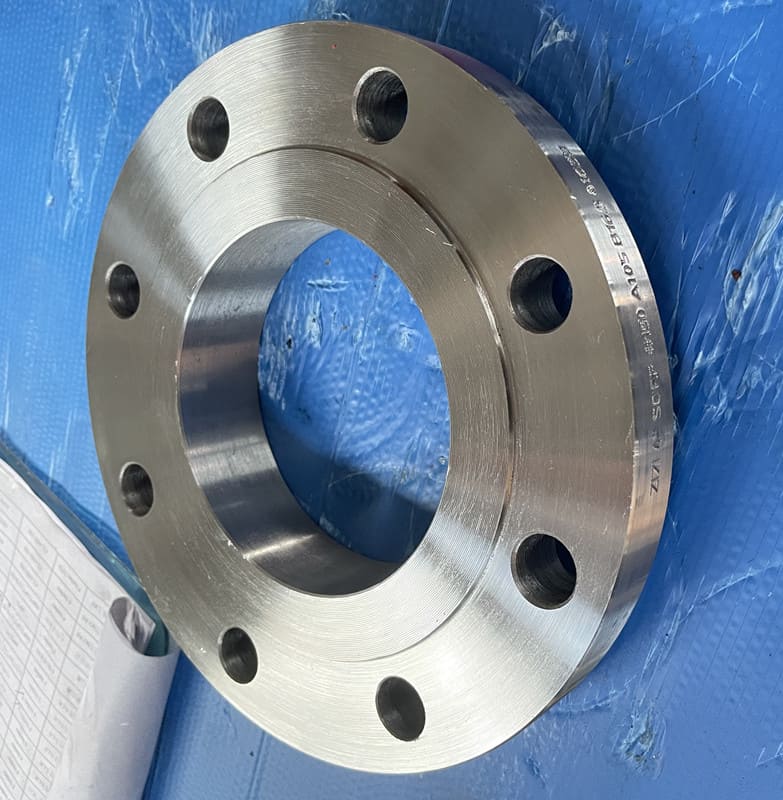

Class 150 F316 Slip On Flange

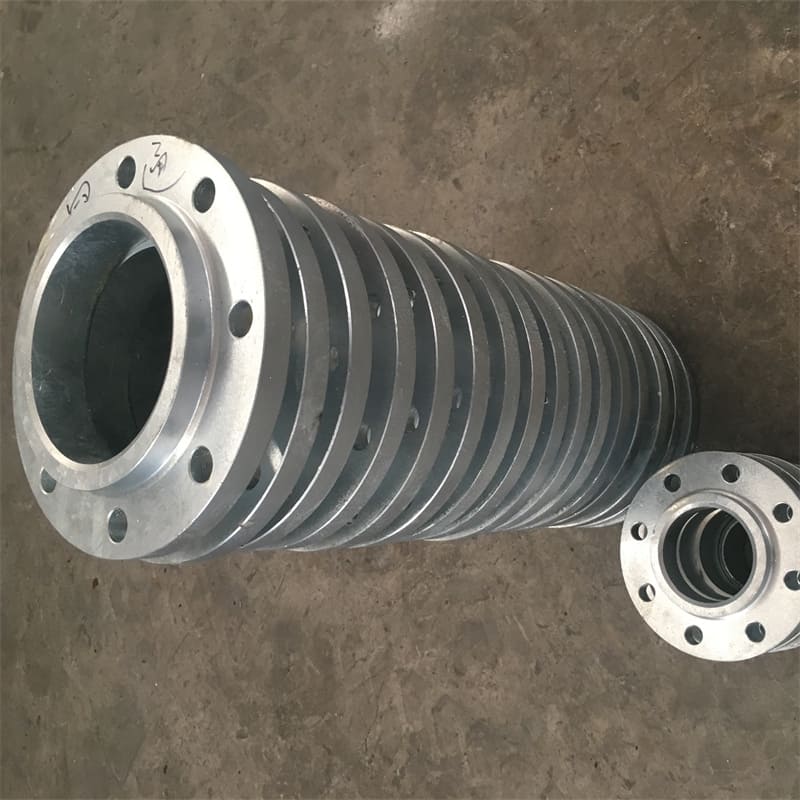

Class 150 F316 slip on flange is a common pipe connection element, mainly made of stainless steel material, through slip on and pipe or other flanges are connected. slip on flange is generally composed of flange plate, bolt hole and sealing surface.

Class 150 F316 slip on flange is a common pipe connection element, mainly made of stainless steel material, through slip on and pipe or other flanges are connected. slip on flange is generally composed of flange plate, bolt hole and sealing surface. The flange plate is the main part of the connection, connected to the pipe or other flange through the bolt holes; the sealing surface is the key part to ensure the sealing performance of the connection.

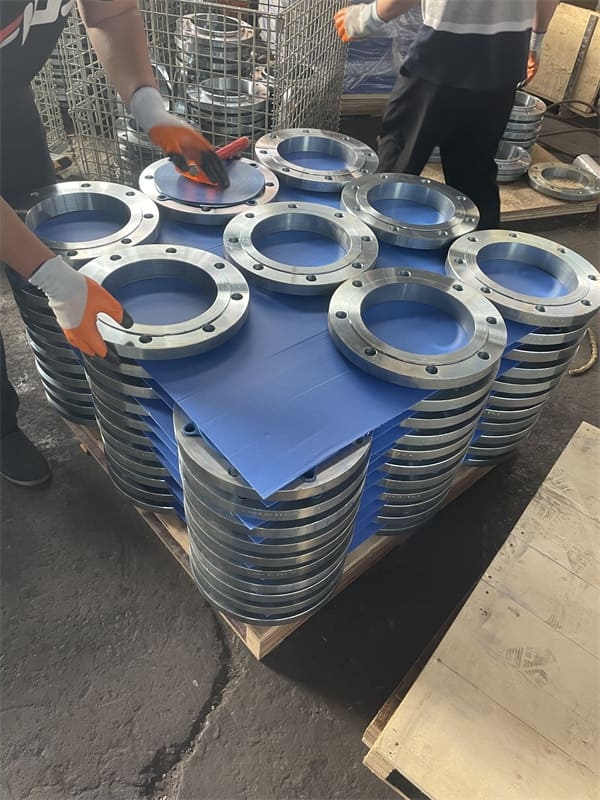

Class 150 F316 slip on flange is widely used in chemical industry, construction, water supply, drainage, petroleum, heavy industry, electric power, shipbuilding and other basic engineering pipeline supporting.

specification of Stainless steel slip on flange

| Sealing Face | RF, FF, FTJ |

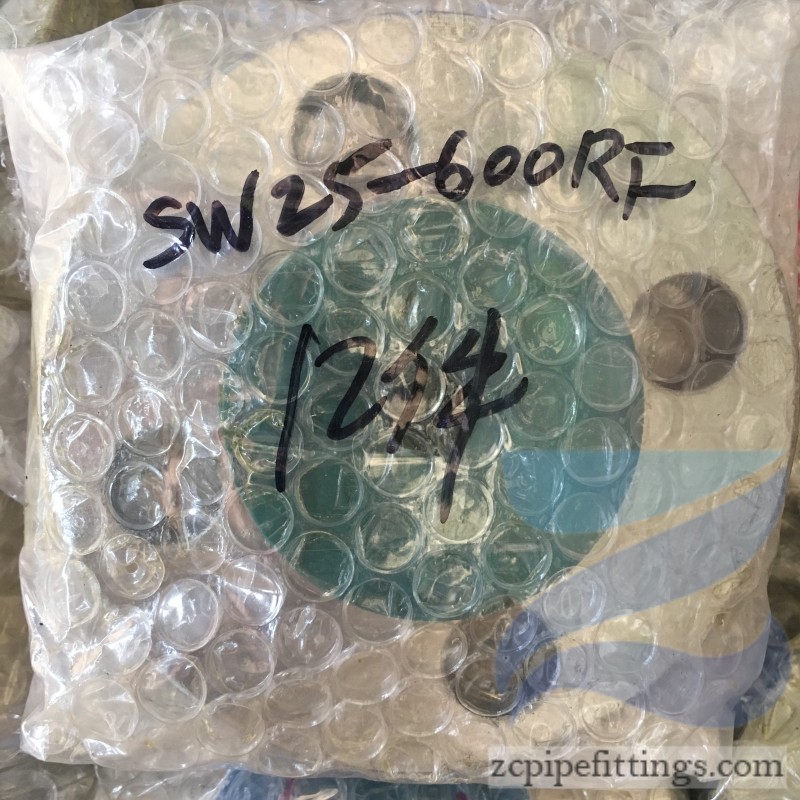

| Size Range | 1/2″ – 24″ / DN15 – DN600 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ANSI / ASME B16.5, EN1092-1 |

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2 / LF3 |

| Pipeline Steel | ASTM A694 F42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

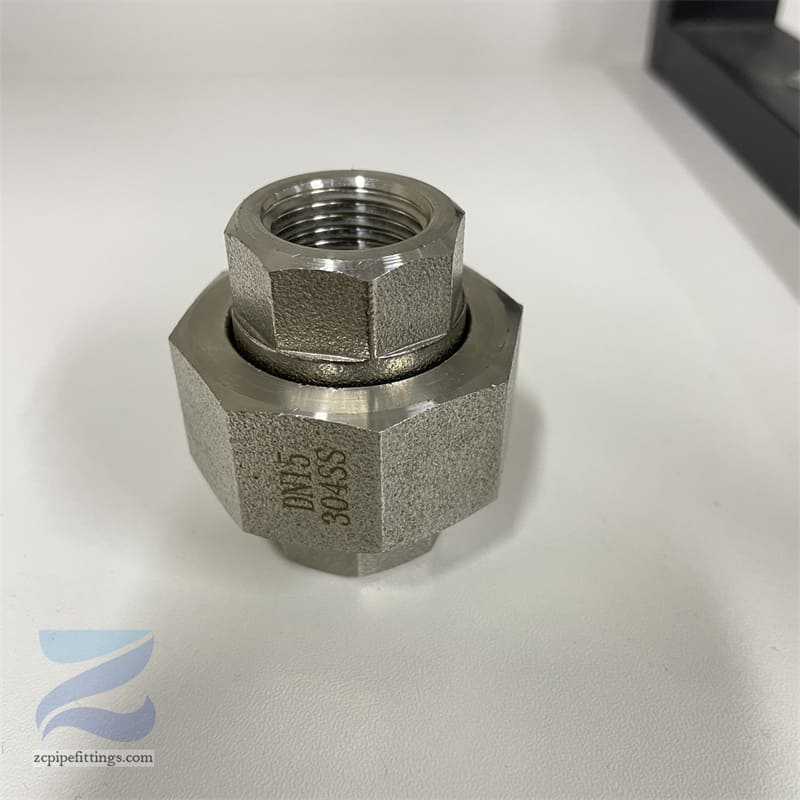

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

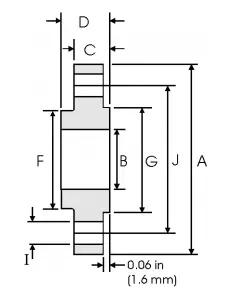

Dimension of F316 stainless Steel Slip On Flange

The dimension of stainless steel slip on flanges are from 1/2” to 24”, and the pressure levels are 150#, 300#, 600#, 900#, 1500#, 2500#

Class 150 stainless steel slip on flange dimensions

| NPS | A | B | C | D | F | G | H | I | J |

| inch | inch | inch | inch | inch | inch | No. of Holes | inch | inch | |

| mm | mm | mm | mm | mm | mm | mm | mm | ||

| 1/2 | 3.50 | 0.88 | 0.44 | 0.62 | 1.19 | 1.38 | 4 | 0.62 | 2.38 |

| 88.90 | 22.40 | 11.20 | 15.70 | 30.20 | 35.10 | 15.70 | 60.45 | ||

| 3/4 | 3.88 | 1.09 | 0.50 | 0.62 | 1.50 | 1.69 | 4 | 0.62 | 2.75 |

| 98.60 | 27.70 | 12.70 | 15.70 | 38.10 | 42.90 | 15.70 | 69.85 | ||

| 1 | 4.25 | 1.36 | 0.56 | 0.69 | 1.94 | 2.00 | 4 | 0.62 | 3.12 |

| 108.00 | 34.50 | 14.20 | 17.50 | 49.30 | 50.80 | 15.70 | 79.25 | ||

| 1 1/4 | 4.62 | 1.70 | 0.62 | 0.81 | 2.31 | 2.50 | 4 | 0.62 | 3.50 |

| 117.30 | 43.20 | 15.70 | 20.60 | 58.70 | 63.50 | 15.70 | 88.90 | ||

| 1 1/2 | 5.00 | 1.95 | 0.69 | 0.88 | 2.56 | 2.88 | 4 | 0.62 | 3.88 |

| 127.00 | 49.50 | 17.50 | 22.40 | 65.00 | 73.15 | 15.70 | 98.60 | ||

| 2 | 6.00 | 2.44 | 0.75 | 1.00 | 3.06 | 3.62 | 4 | 0.75 | 4.75 |

| 152.40 | 62.00 | 19.10 | 25.40 | 77.70 | 91.90 | 19.10 | 120.70 | ||

| 2 1/2 | 7.00 | 2.94 | 0.88 | 1.12 | 3.56 | 4.12 | 4 | 0.75 | 5.50 |

| 177.80 | 74.70 | 22.40 | 28.40 | 90.40 | 104.60 | 19.10 | 139.70 | ||

| 3 | 7.50 | 3.57 | 0.94 | 1.19 | 4.25 | 5.00 | 4 | 0.75 | 6.00 |

| 190.50 | 90.70 | 23.90 | 30.20 | 108.00 | 127.00 | 19.10 | 152.40 | ||

| 3 1/2 | 8.50 | 4.07 | 0.94 | 1.25 | 4.81 | 5.50 | 8 | 0.75 | 7.00 |

| 215.90 | 103.40 | 23.90 | 31.75 | 122.20 | 139.70 | 19.10 | 177.80 | ||

| 4 | 9.00 | 4.57 | 0.94 | 1.31 | 5.31 | 6.19 | 8 | 0.75 | 7.50 |

| 228.60 | 116.10 | 23.90 | 33.30 | 134.90 | 157.20 | 19.10 | 190.50 | ||

| 5 | 10.00 | 5.66 | 0.94 | 1.44 | 6.44 | 7.31 | 8 | 0.88 | 8.50 |

| 254.00 | 143.80 | 23.90 | 36.60 | 163.60 | 185.70 | 22.40 | 215.90 | ||

| 6 | 11.00 | 6.72 | 1.00 | 1.56 | 7.56 | 8.50 | 8 | 0.88 | 9.50 |

| 279.40 | 170.70 | 25.40 | 39.60 | 192.00 | 215.90 | 22.40 | 241.30 | ||

| 8 | 13.50 | 8.72 | 1.12 | 1.75 | 9.69 | 10.62 | 8 | 0.88 | 11.75 |

| 342.90 | 221.50 | 28.40 | 44.50 | 246.10 | 269.70 | 22.40 | 298.50 | ||

| 10 | 16.00 | 10.88 | 1.19 | 1.94 | 12.00 | 12.75 | 12 | 1.00 | 14.25 |

| 406.40 | 276.30 | 30.20 | 49.30 | 304.80 | 323.90 | 25.40 | 362.00 | ||

| 12 | 19.00 | 12.88 | 1.25 | 2.19 | 14.38 | 15.00 | 12 | 1.00 | 17.00 |

| 482.60 | 327.10 | 31.75 | 55.60 | 365.30 | 381.00 | 25.40 | 431.80 | ||

| 14 | 21.00 | 14.14 | 1.38 | 2.25 | 15.75 | 16.25 | 12 | 1.12 | 18.75 |

| 533.40 | 359.10 | 35.10 | 57.15 | 400.10 | 412.80 | 28.40 | 476.30 | ||

| 16 | 23.50 | 16.16 | 1.44 | 2.50 | 18.00 | 18.50 | 16 | 1.12 | 21.25 |

| 596.90 | 410.50 | 36.60 | 63.50 | 457.20 | 469.90 | 28.4 | 539.8 | ||

| 18 | 25.00 | 18.18 | 1.56 | 2.69 | 19.88 | 21.00 | 16 | 1.25 | 22.75 |

| 635.00 | 461.80 | 39.60 | 68.30 | 505.00 | 533.40 | 31.75 | 577.9 | ||

| 20 | 27.50 | 20.20 | 1.69 | 2.88 | 22.00 | 23.00 | 20 | 1.25 | 25 |

| 698.50 | 513.10 | 42.90 | 73.15 | 558.80 | 584.20 | 31.75 | 635 | ||

| 24 | 32.00 | 24.25 | 1.88 | 3.25 | 26.12 | 27.25 | 20 | 1.38 | 29.5 |

| 812.80 | 616.00 | 47.80 | 82.60 | 663.40 | 692.20 | 35.1 | 749.3 |

Application range of stainless steel slip on flanges

Stainless steel slip on flange is widely used in many fields because of its unique material and performance.

Chemical industry: due to the excellent corrosion resistance of stainless steel, slip on flange is widely used in chemical equipment and pipeline system to ensure the stability and safety of the system.

Oil and gas industry: In the process of oil and gas exploitation, transportation and processing, stainless steel slip on flange is used to connect pipelines and equipment to withstand high pressure and high temperature environment to ensure the continuity and safety of fluid transmission.

Construction industry: In the water supply and drainage system, stainless steel slip on flange is used to connect pipes and valves and other equipment, to provide reliable sealing performance.

Pharmaceutical industry: In the connection of pharmaceutical equipment, stainless steel slip on flanges are widely used because of their corrosion resistance and easy cleaning characteristics, to ensure the production quality of drugs.

Advantages of stainless steel slip on flange

Excellent corrosion resistance: stainless steel material has excellent corrosion resistance, can resist the erosion of a variety of chemicals, prolong the service life of the flange.

High strength and rigidity: stainless steel slip on flange has high strength and rigidity, can withstand large pressure and load, to ensure the stability and safety of the connection.

Good sealing performance: Through accurate machining and installation, stainless steel slip on flanges can provide reliable sealing performance, prevent fluid leakage, and ensure the normal operation of the system.

Easy installation and maintenance: stainless steel slip on flange connection mode is simple, easy to install and remove, convenient maintenance and overhaul of equipment.

Beautiful and durable: stainless steel material has silver and white metallic luster, beautiful and generous appearance, and not easy to rust and corrosion, can maintain its good appearance and performance for a long time.