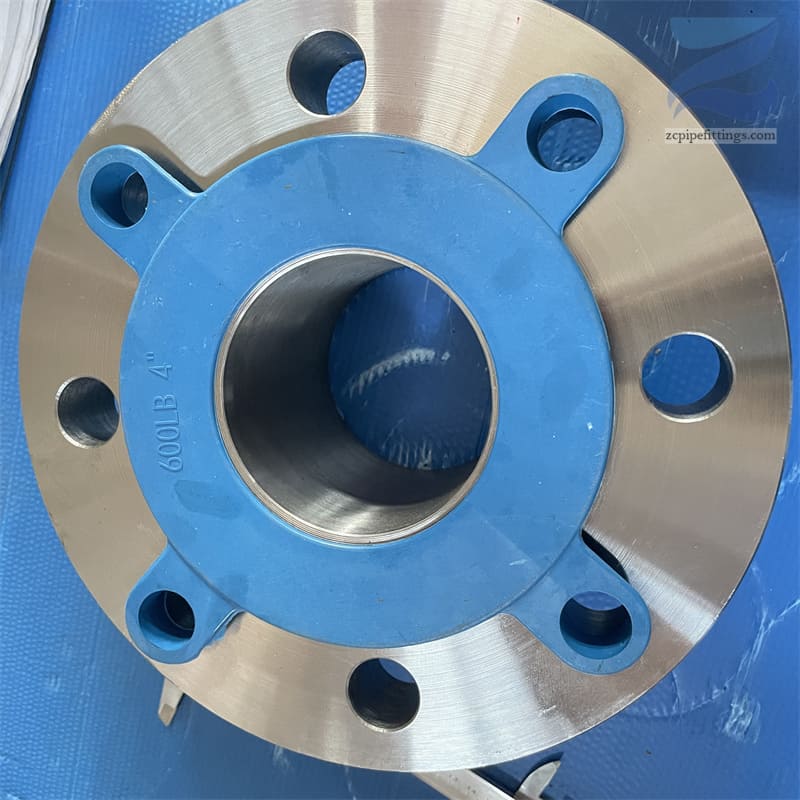

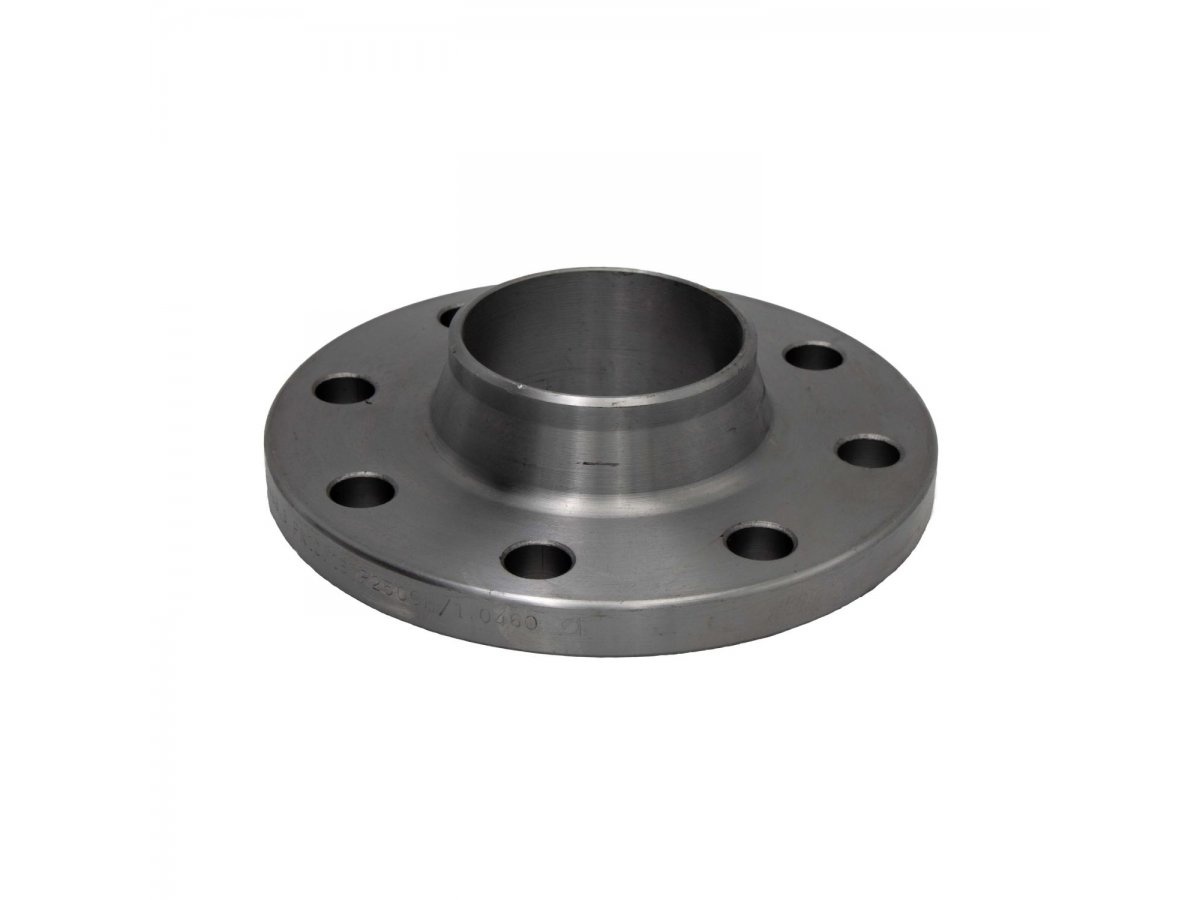

What is Slip On Flange?

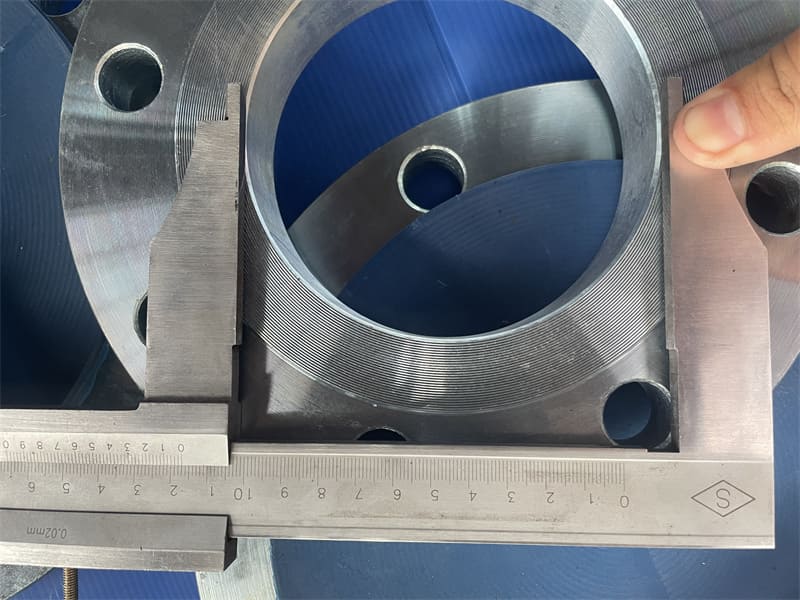

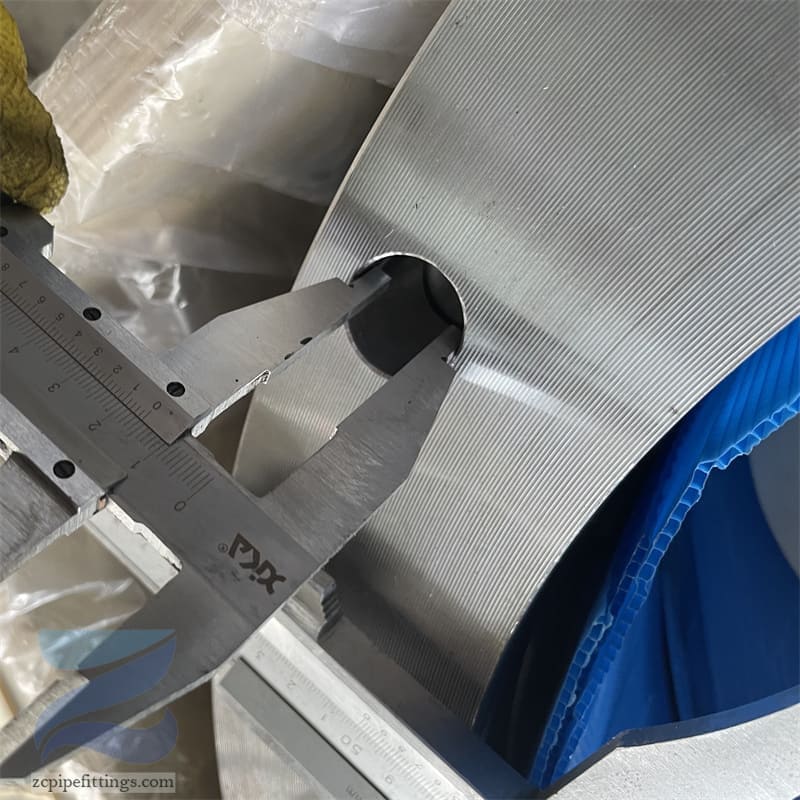

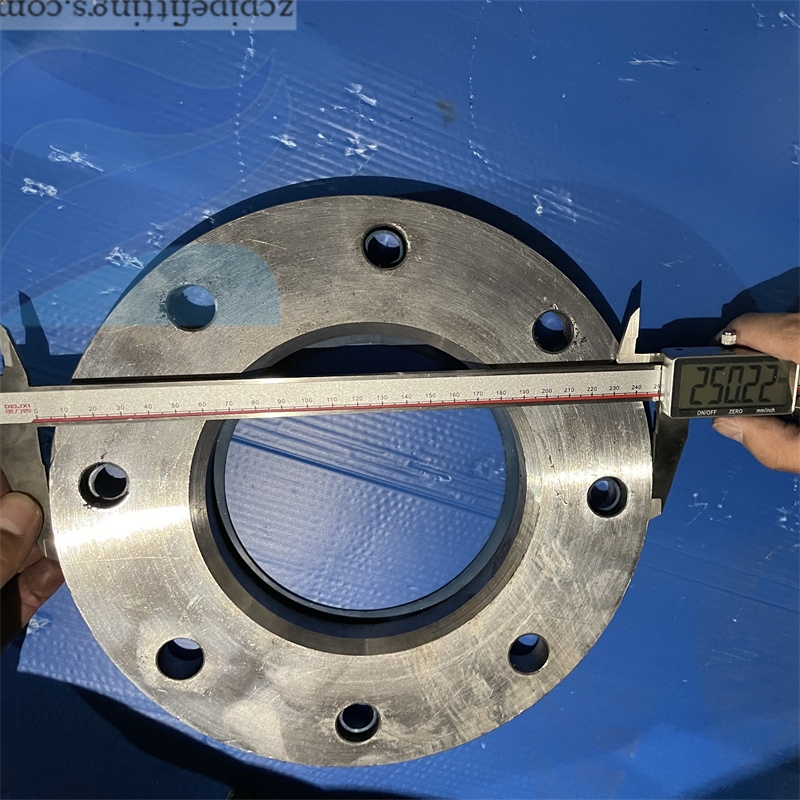

Slip on flange also named as SO flange. SO flanges slip over pipes and are designed to bit slightly bigger on the inside than the pipe. They connect to the pipe through a fillet weld at the flange top and bottom. It is used to insert the pipe into the inner hole of flange, as the flange inner diameter is little bigger than the pipe’s outer diameter, pipe and flange could be connected by lap welding at the top and bottom of the flange.

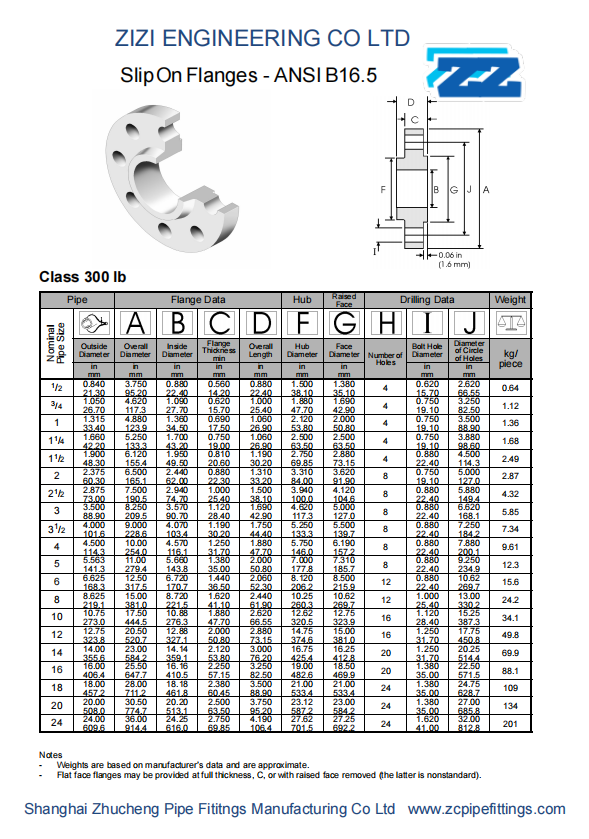

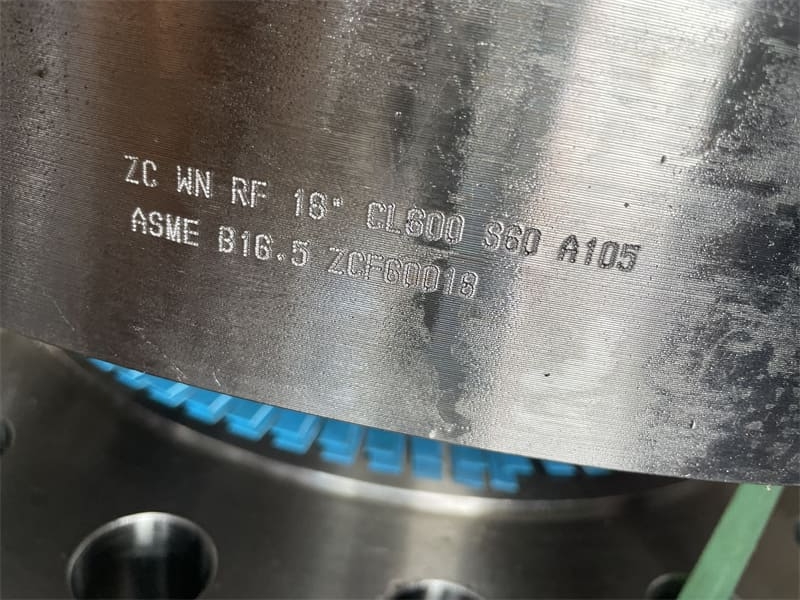

Specification of Slip On Flange

| Sealing Face | RF,FF,FTJ |

| Size Range | 1/2″-24″/DN15-DN600 |

| Pressure Rating | Class150/300/600/900/1500/2500lb |

| America Standard | ASME B 16.5/EN1092-1 |

| Carbon Steel | ASTM A150/A150N |

| Low Tem Carbon Steel | ASTM A350 LF2/LF3 |

| Pipeline Steel | ASTM A694 F42/46/56/60/65 |

| Alloy Steel | ASTM A182 F11/F12/F5/F9/F91/F92 |

| Stinless Steel | ASTM A182 F304/304L/304H,316,316L,310S,317,347,904L |

Advantages of Slip On Flange

Advantages of stainless steel slip on flange: slip on flange not only saves space and reduces weight, but also ensures that the joint will not leak and has good sealing performance. The size of the compact flange is reduced by reducing the diameter of the seal, which will reduce the cross-section of the seal surface. Second, the flange gasket has been replaced by the sealing ring to ensure that the seal faces the matching of the sealing surface. As a result, only a small amount of pressure is needed to compress the sealing surface