Carbon Steel ASTM A105 Threaded Coupling Dimentions

Threaded couplings with a hose tail are intended to be assembled to rubber and plastic industrial hoses. Nominal diameters from 1/2″ (DN13) to 4″ (DN100).

Production Description

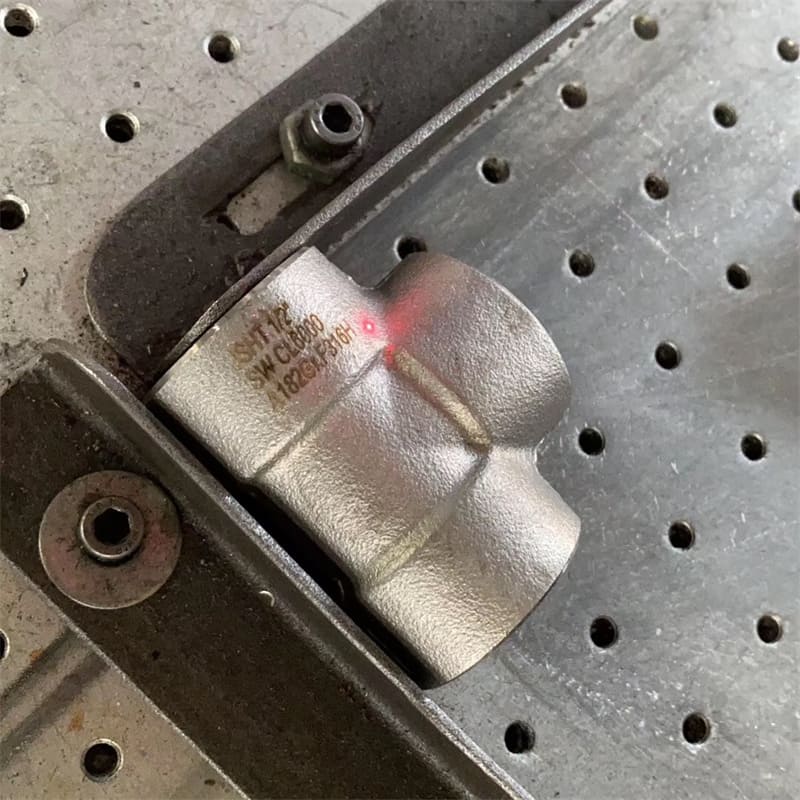

Carbon Steel ASTM A105 Threaded Coupling Dimentions means the coupling has threads at one or both ends. It is a commonly used accessory for industrial pipe connections. They are widely used in various industries, including chemical processing, petroleum, refining, marine waste treatment, utilities / power generation, industrial equipment, natural gas compression and distribution industries. Made of carbon steel, stainless steel, brass or aluminium. Working pressure 25 bar (16 bar for aluminium). They are available separately or as a set with an aluminium safety clamp to suit the inner diameter of a hose and its wall thickness. They can be also crimped with the appropriate ferrules for industrial hoses. They have female or male threads of different kinds: BSP, BSPT, NPT, NPS, metric, ACME, DIN11. Depending on the type of the thread, the connection comes with a flat seal, it is sealed on the cone (metal-metal) or on the thread (with PTFE thread seal tape, liquid or paste sealant). Used for all sorts of media: chemical substances, petrochemical products, liquefied gas – especially in loading/unloading applications. There are also couplings intended for highly aggressive chemical substances, lined with ECTFE – a polymer resistant to chemicals.

Types:

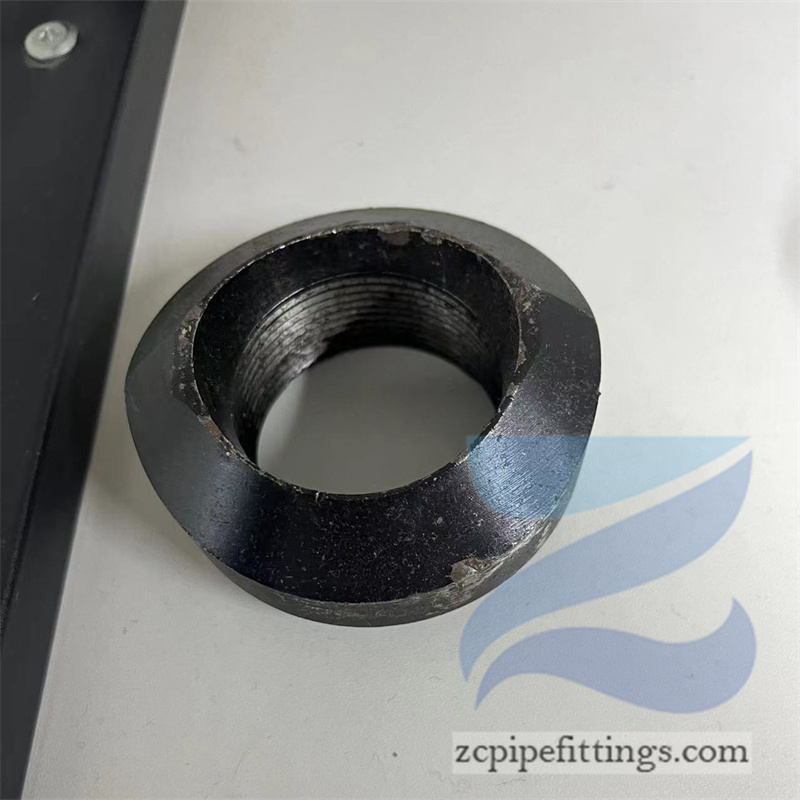

Full Coupling: Both ends of the full thread coupling are threaded.

Half Coupling: One end of a half thread coupling is threaded and the other end is welded.

Shapes:

Straight: It is a kind of pipe coupling with the same diameter at both ends.

Reducing: The two ends of the coupling have different sizes

Product features

- Use with air , water, oil, natural gas, steama.

- NPT and FNPT threasa conform to ASME B1.20.1

- Reducing coupling is used to connect two diffrent sizes of pipe. It is like concentric reducer that maintains a center line of the pipe but small in size.

- Half coupling ids used for small bore branching from a vessel or large pipe. It can be threaded or socket type. It has a socket or thread end only one side.

- Full threaded Coupling is used for connecting small bore pipes. It used to connect pipe to swage or nipple. It can be threaded socket ends types.

Specificaton of Carbon Steel ASTM A105 Threaded Coupling Dimentions

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

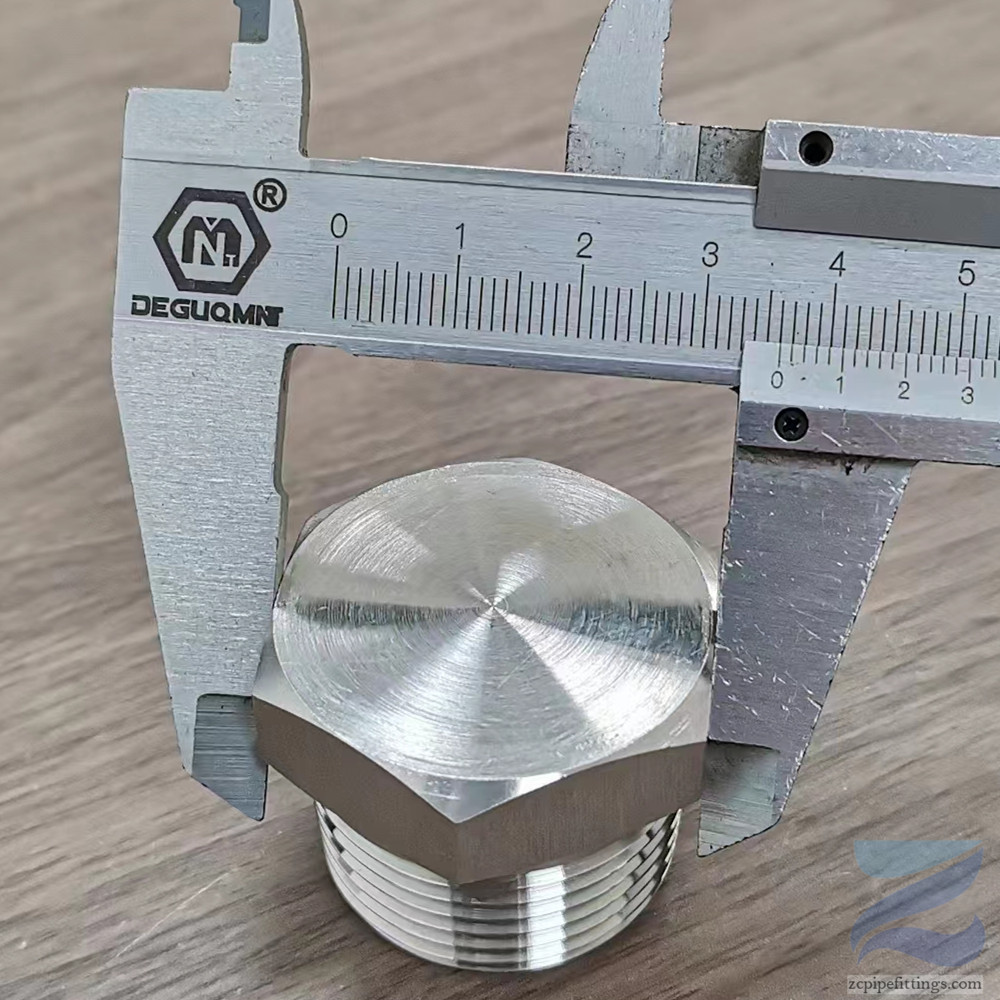

Threaded Coupling Dimensions & Size

Forged Threaded Coupling Weight Chart in KG

Carbon Steel ASTM A105 Threaded Coupling Dimentions can be forged at temperatures in the range of 2200 to 1700 F followed by quenching and tempering or normalizing. The actual hot forging temperatures in process will be decided by a number of factors, such as complexity of the forged part.

The proper temperature of forging can only be checked at the beginning of forging, higher temperature will probably cause surface defects, such as mill scales, which will bring uneven surface. And lower temperature will be not conducive to the plastic deformation of C1045 carbon steel forged part.

A105 forgings are limited to a maximum weight of 4540 kg [10000 lb]. As stated in our quality manual, welding repair of defects in ASTM A105 flanges or fittings is absolutely prohibited by Metals-Piping(although it is permissible by the standard).

Heat Treatment

Heat treatment is not required except for ASTM A 105 carbon steel forging. However, there are some exceptions that will require heat treatment to improve its mechanical properties for better application.The typical heat treatment conducted for A105 carbon steel forgings includes annealing(A), normalizing(A), normalizing and tempering(NT), quenching and tempering(QT). Especially, normalizing at approximate 950°C for 2.5 hours is often required by many clients to eliminate possible internal stress in the forgings. These materials are usually marked as “ASTM A105N”.

ASTM A105 (High-temperature carbon steel flange material)

| C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V | |

| A105 | – | 0.60 | – | – | 0.10 | – | – | – | ||

| 0.35 | 1.05 | 0.035 | 0.040 | 0.35 | 0.40 | 0.40 | 0.30 | 0.12 | 0.08 |

Chemical composition of ASTM A105 carbon steel material:

| Element | Composition % |

| Carbon | 0.35 max |

| Manganese | 0.6-1.05 |

| Phosphorus | 0.035 max |

| Sulfur | 0.040 max |

| Silicon | 0.10–0.35 |

| Copper | 0.40 max |

| Nickel | 0.40 max |

| Chromium | 0.30 max |

| Molybdenum | 0.12 max |

| Vanadium | 0.08 max |

| Columbium | 0.02 max |

Application:

- Petroleum

- Pulp/paper

- Refining

- Textile

- Waste treatment, Marine

- Utilities/power generation

Dementions Details