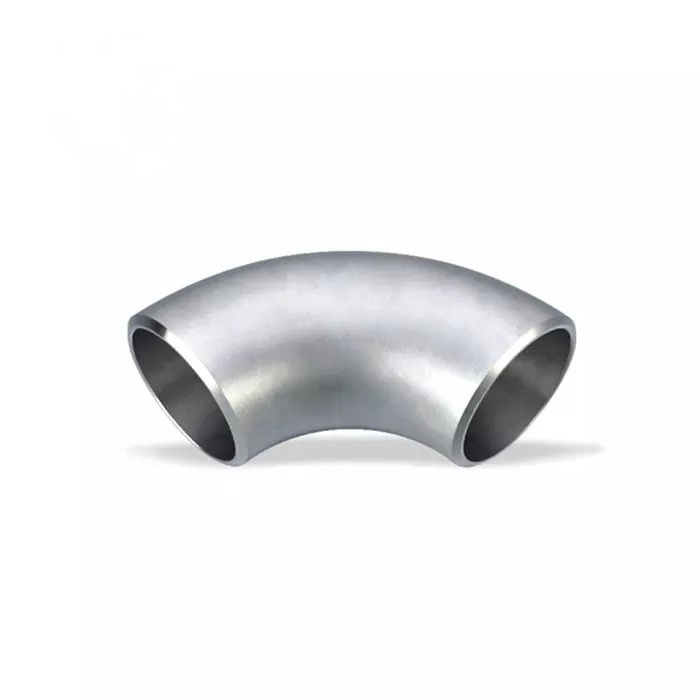

Carbon Steel A234WPB Butt Weld Cap Dimensions

Steel pipe cap is usually welded onto end of pipe that blcok off the piping line system, it has same funtion with plug and blind flange. It is available in material of carbon steel, stainless steel and alloy steel.

Production Description

Carbon Steel A234WPB Butt Weld Cap Dimensions also known as steel plug, is usually welded on the pipe end or installed on the external thread of the pipe end to cover the pipe fittings. BW steel pipe cap is a butt welded pipe fitting, and the connection method is butt welding. Therefore, the end of BW pipe cap is inclined or flat. Within the scope of butt welded pipe parts, the steel pipe cap is directly welded with the pipe to prevent the flow in the pipe system. The pipe cap has various shapes, such as semi spherical, oval, circular, etc.The pipe cap acts as a protective device to protect the pipe ends of various shapes, and can also be used to close the ends of hydraulic or pneumatic pipes. The main purpose of using pipe cap is waterproof connection.

Product features

- Steel Pipe Cap is also called Steel Plug, it usually welded to the pipe end or mounted on the external thread of the pipe end to cover the pipe fittings.

- To close the pipeline so the function is the same as the pipe plug.

- It keeps the inside pipe clean from dirt, debris, and animals. The Steel Cap fits on the outer diameter (O.D.) of the pipe.

- BW steel pipe cap is the butt weld type of fittings, connecting methods is to use butt welding. So BW cap ends in beveled or plain.

Specificaton of Stainless Steel A403 WP304L Butt Weld Cap Dimentions

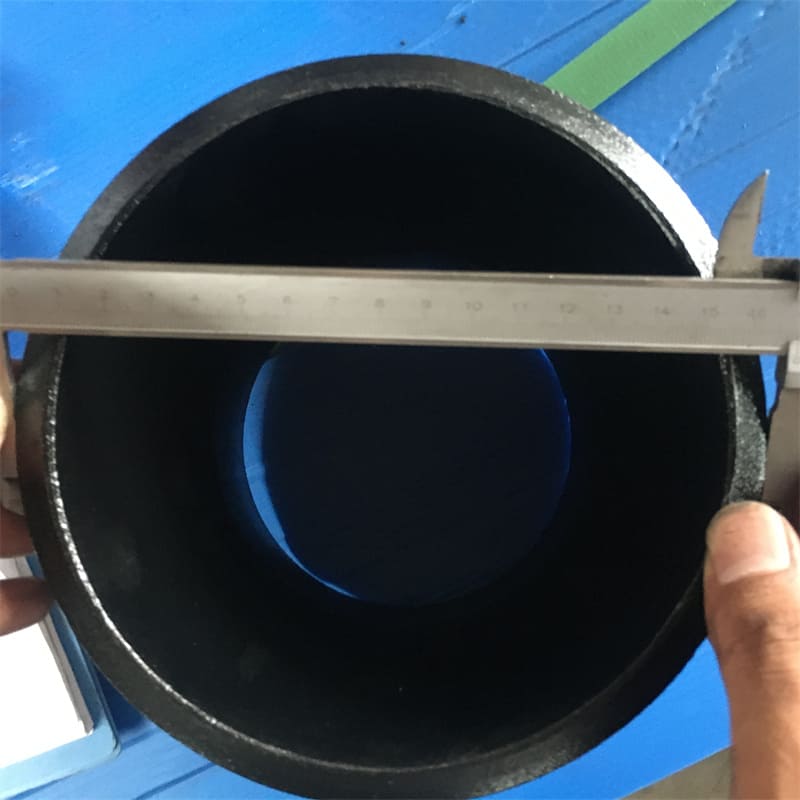

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

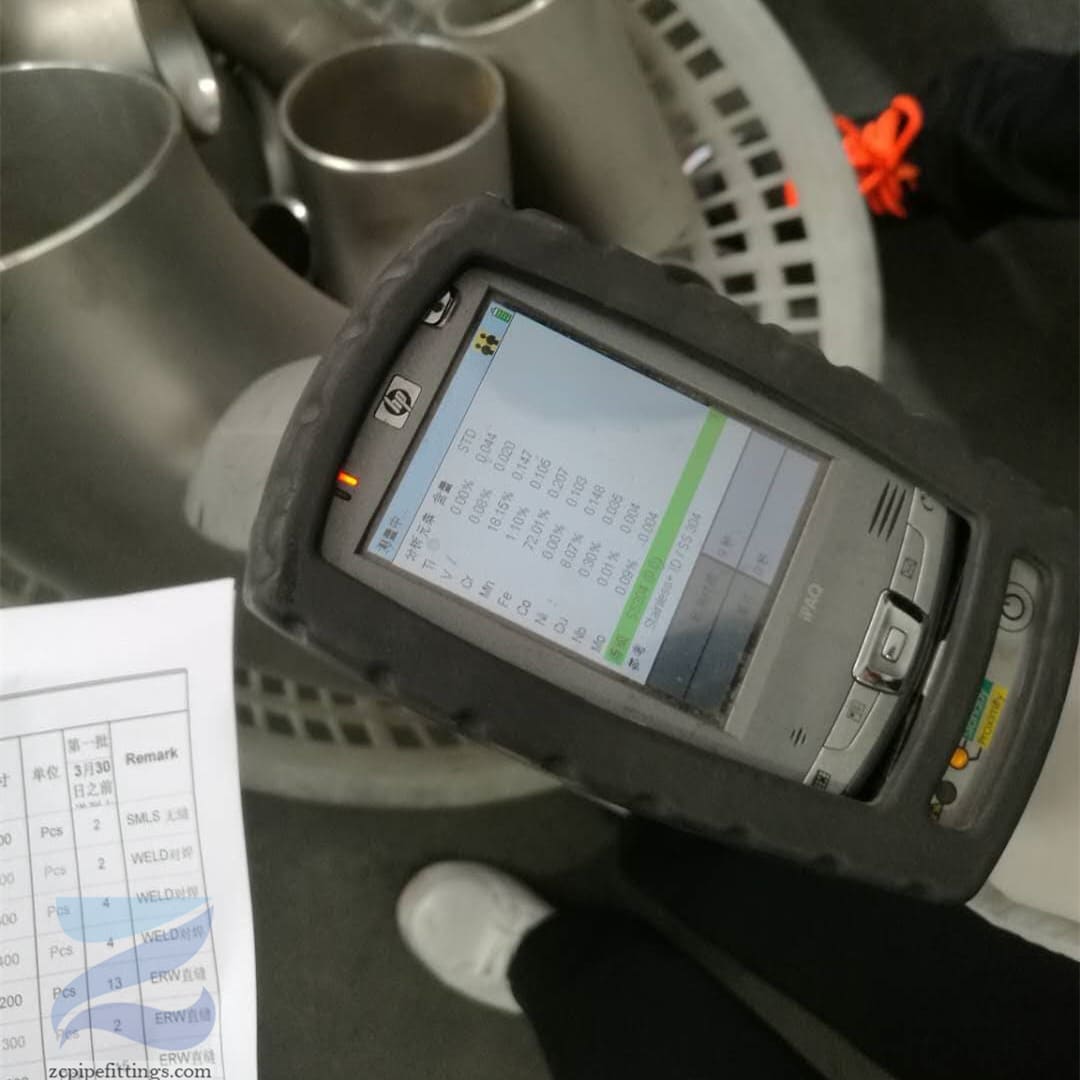

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Steel Pipe Cross Fittings Drawing