Carbon Steel A234 WPB Butt Weld 90 Degree Elbow Dimensins

ASTM A234 specification has many grades, such as WPB, WPC, WP5, WP9 WP11, WP12, WP22, WP91 and so on.

In these standard Grade WPB is the most common material used for medium and high temperature pipelines. W means weldable, P means pressure, B is grade b, refer to the minimum yield strength.

Carbon Steel A234 WPB Butt Weld 90 Degree Elbow Production Description

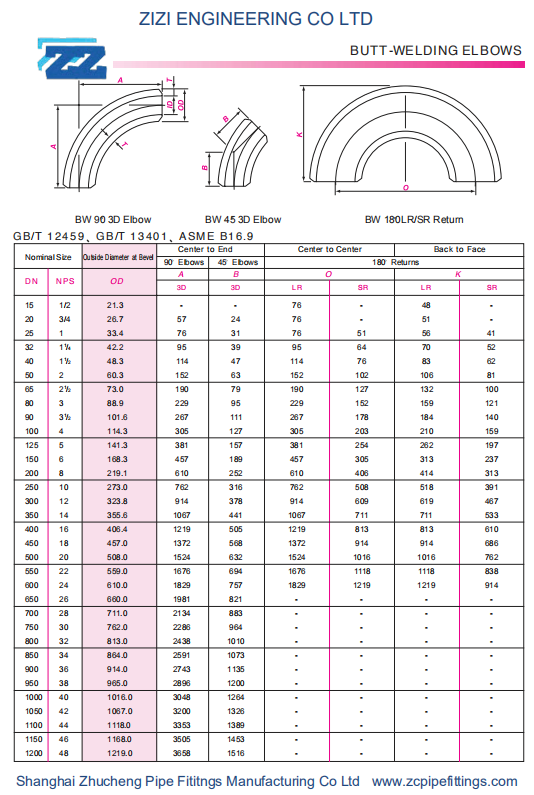

The function of butt weld elbow is to change direction or flow in a piping system. There are the 45°, 90° and 180° .

According to the material, it can be divided into carbon steel, alloy steel and stainless-steel.

According to its radius of curvature, there are long radius and short radius Stainless Steel A403 Butt Weld 90 Degree Elbow. Long radius elbow refers to its radius of curvature is equal to 1.5 times the outside diameter of the pipe, that is, R=1.5D; A short radius elbow means that its radius of curvature is equal to the outer diameter of the pipe, that is, R= 1.0d.(D is the diameter of the elbow, and R is the radius of curvature).

Butt weld fittings are manufacture by seamless or welded pipe. For pipe fittings manufacturers, the forming process of welded pipe and seamless pipe is basically same. Butt welded fittings can be divided into carbon steel butt welded fittings and stainless-steel butt-welded fittings

Carbon Steel A234 WPB Butt Weld 90 Degree Elbow Dimensins and Material

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

Material

Carbon Steel A234 WPB Butt Weld 90 Degree Elbow have been widely applied in pipeline systems.

It covers steel fittings of seamless and welded types. Steel Pipe fittings are applied in pressure pipelines and in pressure vessel fabrications.

ASTM A234 specification has many grades, such as WPB, WPC, WP5, WP9 WP11, WP12, WP22, WP91 and so on.

In these standard Grade WPB is the most common material used for medium and high temperature pipelines. W means weldable, P means pressure, B is grade b, refer to the minimum yield strength.

| ITEM | HEAT NO. | SPECIFICATION | QTY | UNIT | CHEMICAL COMPOSITION (%) | ||||||||||||||

| C | Si | Mn | S | P | Cr | Ni | Cu | Mo | V | N | Ti | ||||||||

| 1 | 70859 | 90DEGREE ELBOW 8″ SCH120 SMLS BW | 3 | PCS | 0.18 | 0.25 | 0.63 | 0.011 | 0.005 | 0.06 | 0.05 | 0.11 | 0.06 | 0.01 | / | / | |||

| 2 | 40818 | 90DEGREE ELBOW 8″ STD SMLS BW | 42 | PCS | 0.21 | 0.35 | 0.81 | 0.006 | 0.003 | 0.05 | 0.03 | 0.15 | 0.03 | 0.01 | / | / | |||

| 3 | 50716 | 90DEGREE ELBOW 6″ SCH40 SMLS BW | 5 | PCS | 0.19 | 0.31 | 0.67 | 0.009 | 0.006 | 0.03 | 0.06 | 0.09 | 0.05 | 0.02 | / | / | |||

| 4 | 50625 | 90DEGREE ELBOW 4″ SCH40 SMLS BW | 5 | PCS | 0.22 | 0.37 | 0.83 | 0.012 | 0.009 | 0.08 | 0.03 | 0.13 | 0.08 | 0.01 | / | / | |||

| 5 | 90153 | 90DEGREE ELBOW 3″ XXS SMLS BW | 1 | PCS | 0.20 | 0.28 | 0.75 | 0.008 | 0.005 | 0.07 | 0.05 | 0.08 | 0.05 | 0.01 | / | / | |||

| ITEM | TENSILE TEST | PMI | NDT | IMPACT TEST (ISO-V) | INTERGRANULAR CORROSION TEST | ||||||||||||||

| Y.S | T.S | EL | R/A | HARDNESS | DIR. | W | TEM. | ABSORBED ENERGY(J) | |||||||||||

| MPA | MPA | % | % | HRB | L./TR. | MM | ℃ | 1 | 2 | 3 | |||||||||

| 1 | 285 | 490 | 35 | / | 170 | / | OK | / | / | / | / | / | / | / | |||||

| 2 | 290 | 485 | 36 | / | 171 | / | OK | / | / | / | / | / | / | / | |||||

| 3 | 280 | 480 | 33 | / | 165 | / | OK | / | / | / | / | / | / | / | |||||

| 4 | 293 | 475 | 35 | / | 168 | / | OK | / | / | / | / | / | / | / | |||||

| 5 | 283 | 491 | 32 | / | 169 | / | OK | / | / | / | / | / | / | / | |||||

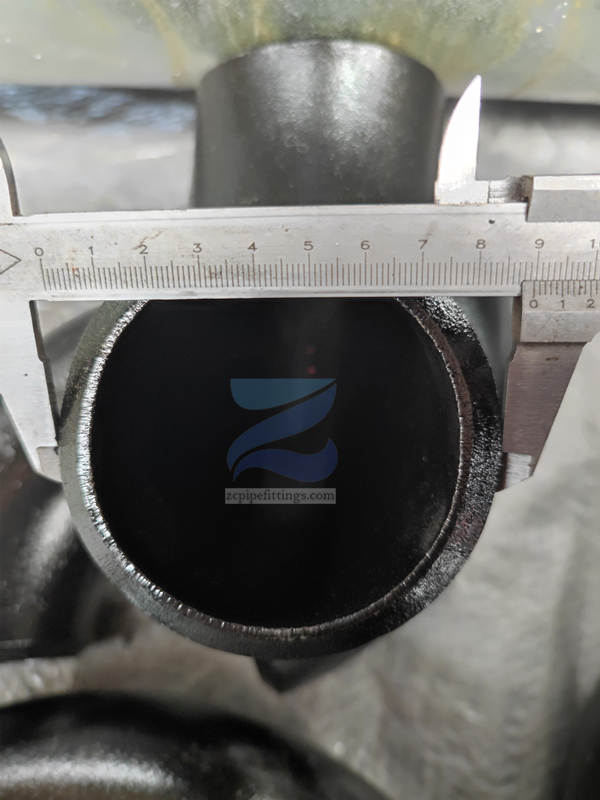

Carbon Steel A234 WPB Butt Weld 90 Degree Elbow Dimensions Measurement