Concept of Buttwelding elbow

BW elbow is one type of steel pipe fittings which used to change direction of the pipeline.It can be divided into long radius (LR) and short radius (SR). Other commonly used elbows in fluid pipeline engineering construction include 45° /90°/180° elbows. Our company can also customize other non-standard elbows according to the needs of the project.We provide carbon steel, stainless steel and aluminum elbow for the overseas projects.

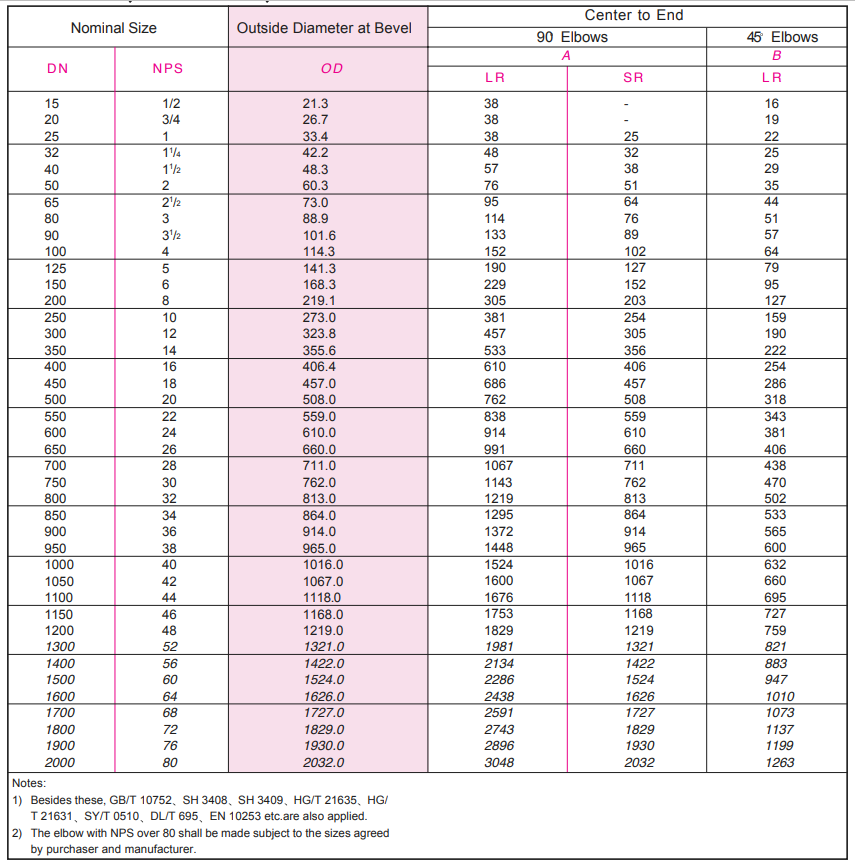

Specifications

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Bending Radius | Long Radius (LR) and Short Radius (SR) |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

BW elbow production requirements

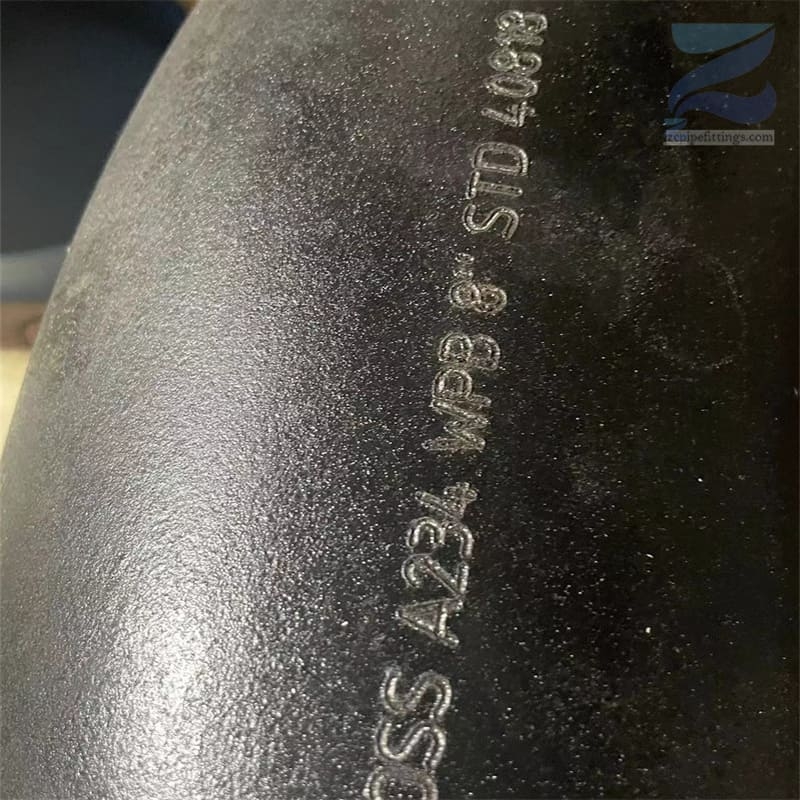

The connection method of the parts of the elbow is mostly completed by the welding process. In order to ensure high quality, the end of the elbow is beveled, a certain slope is reserved, and the elbow has an edge, all of which need to be strictly controlled. , the inclination and the edge size all have a certain numerical area size, and the surface manufacturing of the elbow is not much different from the manufacturing of the pipe.

The components contained in the elbow need to be re-treated on the surface. The oxidized inner and outer layers of the elbow are evenly coated with anti-rust paint through the spraying process, which is convenient for product transportation and export to foreign markets, reducing wear and tear of elbow products , which is a very important process.