Home » Buttwelding Fittings » butt weld elbow ASME B16.9 SCH10-SCH XXS

Previous:

ASTM A234 BW 90 DEG ELBOW DN15-2000

Content

90° elbow production requirements

- The parts of the elbow are mostly connected by welding process. In order to ensure high quality, the end of the elbow is beveled, a certain slope is reserved, and the edge of the elbow is strictly controlled. , the inclination and edge size all have a certain numerical area size, and the surface manufacturing of the elbow is not much different from the pipe manufacturing.

- The components contained in the elbow need to be treated again on the surface. The inner and outer layers of the oxidized elbow are evenly coated with anti-rust paint through the spraying process, which is convenient for product transportation and export to foreign markets, so that the elbow products can reduce wear and tear, which is a very important process.

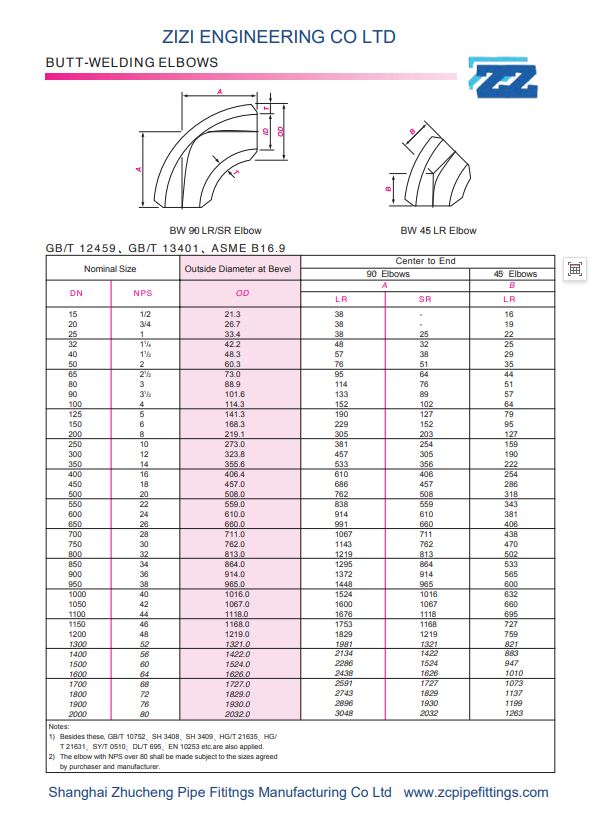

Specifications

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Bending Radius | Long Radius (LR) and Short Radius (SR) |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Inquiry

More Buttwelding Fittings