Butt Weld 45 Degree Elbow

The Butt Weld 45 Degree Elbow is a pipe connector in the shape of a curved pipe section with a bending angle of 45°. It consists of a curved part and straight edge parts at both ends. The radius of curvature of the curved part is an important parameter, which is usually determined according to the nominal diameter of the pipe and the use requirements.

The Butt Weld 45 Degree Elbow is a pipe connector in the shape of a curved pipe section with a bending angle of 45°. It consists of a curved part and straight edge parts at both ends. The radius of curvature of the curved part is an important parameter, which is usually determined according to the nominal diameter of the pipe and the use requirements.

The interface at both ends is a butt welding joint. The butt weld joint requires high processing accuracy to ensure that it can be accurately connected with the adjacent pipe or pipe fitting during welding. The edge of the interface usually needs to be chamfered, on the one hand to facilitate the welding operation and enable the weld to be better filled; on the other hand to remove defects such as burrs on the edge and improve the welding quality.

Specification of ASME B16.9 45 Degree Elbow

| Size Range | 1/2″- 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10, 20, 40, STD, XS, 80, 100, 120, 140, 160, XXS |

| Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409, ANSI / ASME B16.9, MSS SP 43, JIS B2311/2312/2313, EN10253, DIN2605/2615/2616/2617, EN10253 |

| Carbon Steel Grades | ASTM A234 WPB/WPC, A420 WPL6, A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel Grades | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92, 15CrMoG,

12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel Grades | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317, 347, 904L |

| Duplex Stainless Steel Grades | ASTM A815 S32205, S31803, 32750, 32760 |

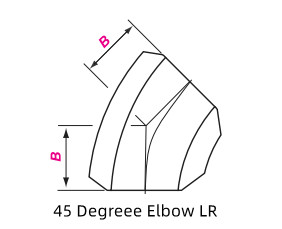

45 Degree Elbow Long Radius Dimension

B

B