BS3799 F304 Threaded Pipe Fittings

BS3799 F304 Threaded Pipe Fittings are named by its manufacturing forging process and produced according to ASME B16.11, MSS-SP-79\83\95\97 and BS3799 standards.

Shanghai Zhucheng manufacture specilized in High pressure BS3799 F304 Threaded Pipe Fittings . There are various types, such as Threaded Elbow, Cross, Tee, Coupling, Half Coupling, Boss, Cap, Union and Sockolet.

BS 3799: 1974 Specification for steel pipe fittings, threaded and socket-welding for the petroleum industry. This standard covers ratings, dimensions, tolerances, marking, and material requirements for both Socket Weld Fittings and Threaded Fittings.

BS3799 F304 Threaded Pipe Fittings are named by its manufacturing forging process and produced according to ASME B16.11, MSS-SP-79\83\95\97 and BS3799 standards. It is a connector in between nominal bore pipes. Their material can be made of carbon steel A105 and stainless steel SS316 & 304. Threaded fittings are mainly used for small pipe diameters, generally for piping whose nominal diameter is NPS 2 or smaller. Threaded joints probably represent the oldest method of joining piping systems.

Threaded Elbow is a pipe fitting that changes the direction of piping. According to the Angle, there are 45° and 90°180° three most commonly used. 90° Elbow material can be divided into carbon steel, alloy steel and stainless-steel.

Steel pipe elbow can be divided into 3 types as buttweld, threaded, socket weld in accordance with connection. The material specification are ASTM A234, A182, A403, A105, A694, A350, A420 and A860.

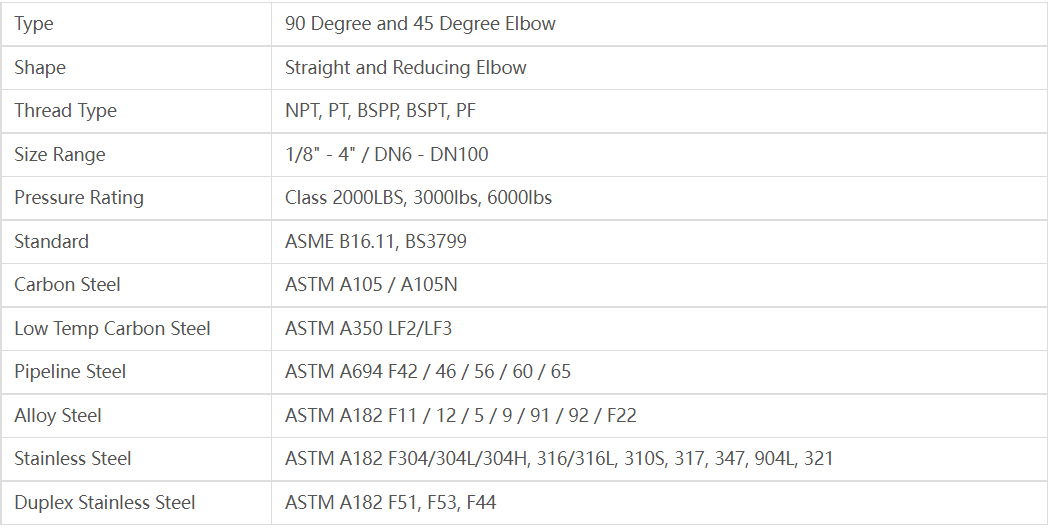

| Threaded Pipe Fittings Specification | |

| Shape | Elbow,Tee, Cross, Coupling, Cap, Swage Nipple, Bushing, Plug, Nipple, Union, Hex Nipple,Threadolet. |

| Size Range | 1/8″ – 4″ / DN6 – DN100 |

| Pressure Rating | Class 2000lbs, 3000lbs, 6000lbs |

| Thread Type | NPT, PT, BSPP, BSPT, PF |

| Standard | ASME B16.11, BS3799, EN 10241, MSS SP-83, MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L,1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Threaded Elbow Material and Size

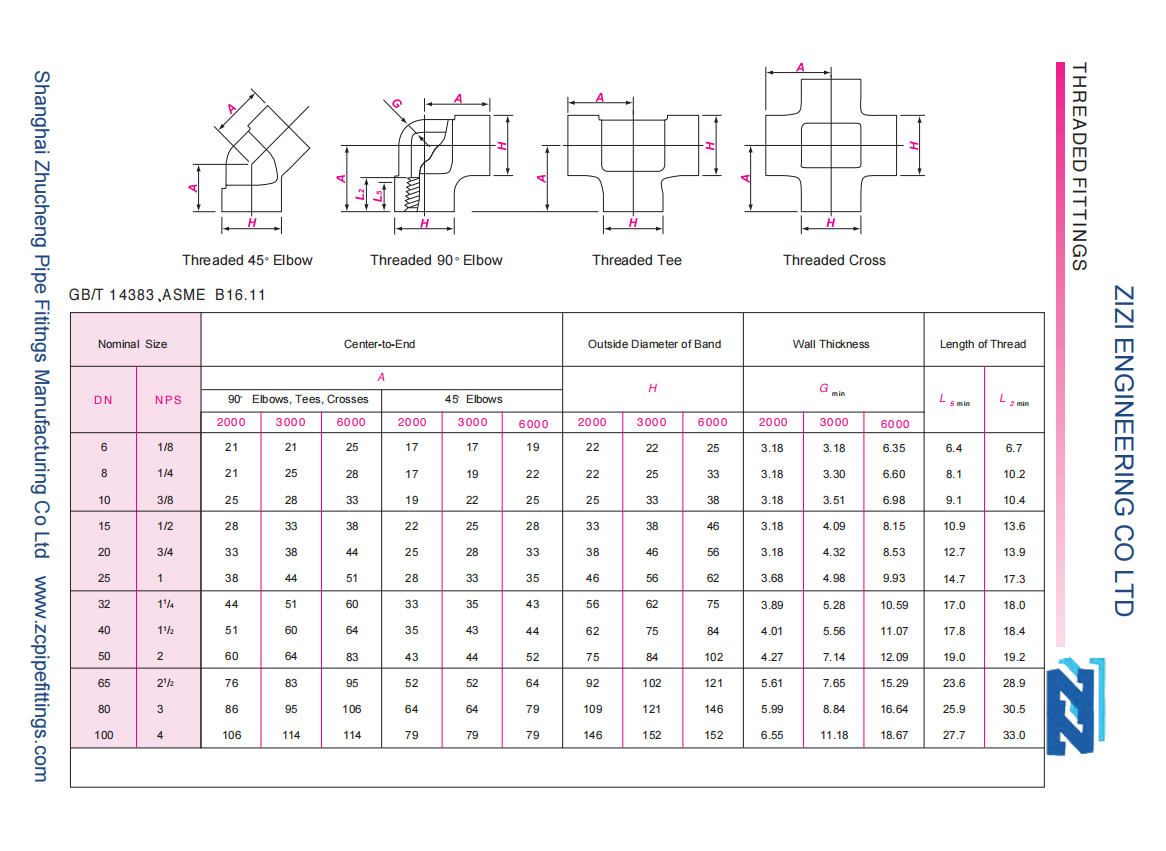

threaded elbow Dimensions Drawing

BS3799 F304 Threaded Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

BS3799 F304 Threaded Pipe Fittings Mechanical Properties

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

BS3799 F304 Threaded Pipe Fittings Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18-09 | X5CrNi18-10 |

Application of BS3799 F304 Threaded Pipe Fittings

Oil and Gas

Chemical

Water Pipeline

Noncritical Applications

Power station

Fire Protection