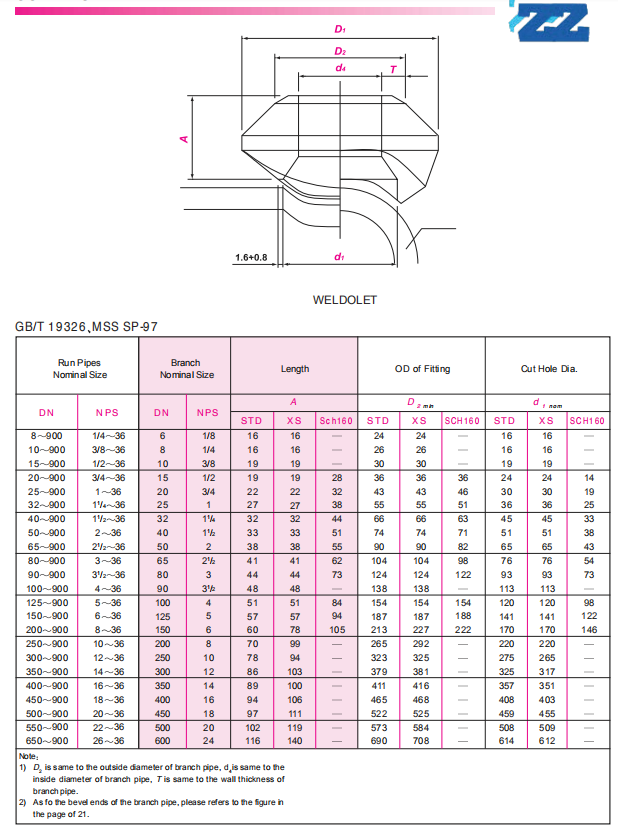

Branch Connection Fittings Weldolet for piping

Size Range: 1/8″ – 24″ / DN6 – DN600

Schedule Chart: STD, XS, SCH 160

Standard: MSS SP-97

Carbon Steel: ASTM A105 / A105N

Low Temp Carbon Steel: ASTM A350 LF2/LF3

Pipeline Steel: ASTM A694 F42/46/56/60/65

Alloy Steel: ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22

Stainless Steel: ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L

Duplex Stainless Steel ASTM A182 F51, F53, F44

Pipe branch fittings are used to create integrally reinforced connections from a run pipe (header pipe) to an outlet pipe, at 45 or 90 degrees, alternatively to connections made with buttweld tees, reinforcing pads and saddles. This type of forged fittings are otherwise called “branch connections”, or “branch fittings”, or “pipe branch outlet fittings” or, simply, “Olets”.

Outlet fittings are forged products with high strength and clear cost advantages over conventional pipe branching techniques.

Weldolets are used to provide an outlet area from a larger to a smaller pipe connection point.

| Specification of Weldolet Fittings | |

| Size Range | 1/8″ – 24″ / DN6 – DN600 |

| Schedule Chart | STD, XS, SCH 160 |

| Standard | MSS SP-97 |

| Carbon Steel | ASTM A105 / A105N |

| Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

| Pipeline Steel | ASTM A694 F42/46/56/60/65 |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 / 22 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317, 347, 904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Weldolet Drawing and Dimension