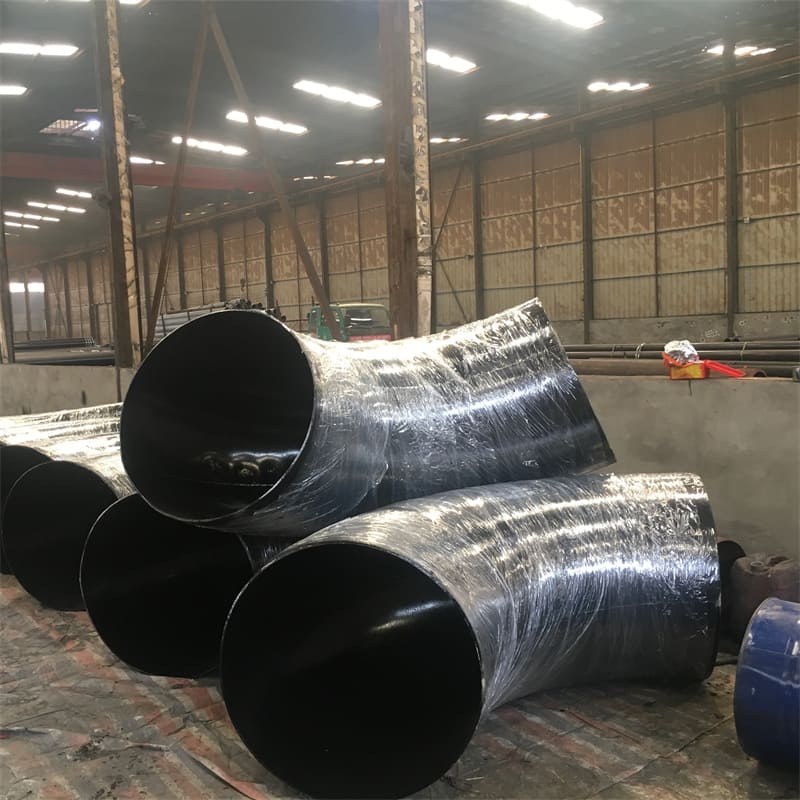

What is a 90 degree elbow?

The 90° pipe elbows is used to connect tubes at a 90° angle. As the name suggests, the elbow is always a right-angle in shape. Such type of elbow is also known as “90 bends or 90 ells”. This is a pipe fitting device which is bent in such a way to produce 90° change in the direction of flow of the fluid/gas in the pipe. The elbow is used to change the direction in piping and is also sometimes called a “quarter bend”.

Classify of elbows

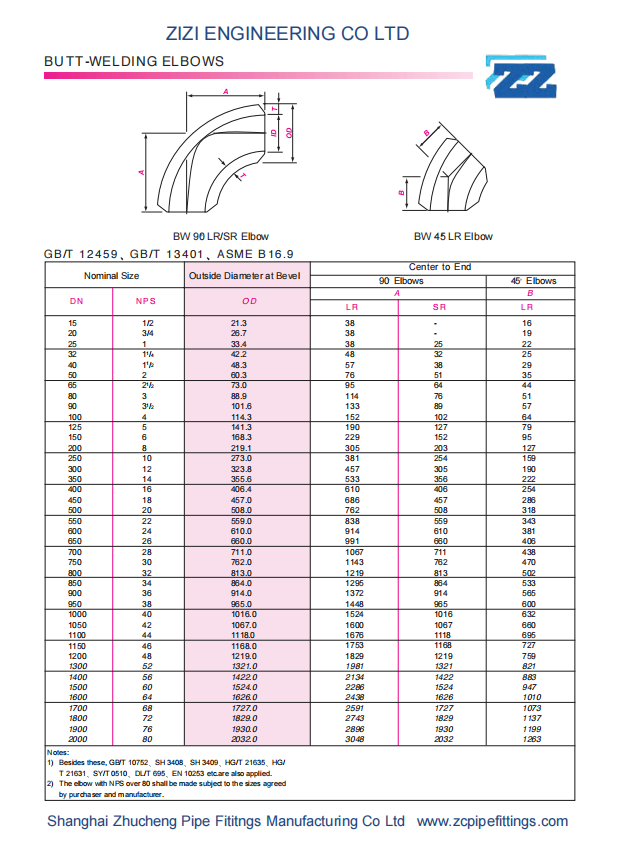

Long Radius Elbow :

The most common is long radius (L.R.) elbow where the centre to face dimension (A) is always 1 ½ times the nominal pipe size of the elbow.

Short Radius Elbow :

In this case the centre dimension(A) is the same as the nominal pipe size of the elbow.

Extra Long Radius :

This is where the centre to face dimension is longer than the standard long radius type. The most common of these is where the centre to face dimension is three nominal size, i.e. 3D

Specification of 90 degree elbow

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Bending Radius | Long Radius (LR) and Short Radius (SR) |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |