ASTM B16.9 SCH80 A234WPB Tee Fittings

Tee welding joints are formed when two pieces intersect at a 90° angle. This results in the edges coming together in the center of a plate or component in a ‘T’ shape. Tee joints are considered to be a type of fillet weld, and they can also be formed when a tube or pipe is welded onto a base plate.

What is a Butt Weld (Buttweld) Fitting?

A buttweld fitting is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment. Forged Steel buttweld fittings are manufactured in accordance with ANSI / ASME B16.9.Butt weld fittings are available as elbows, tees, caps, reducers and out lets (olets). These fittings are the most common type of welded pipe fittings and are specified by nominal pipe size and pipe schedule. Buttweld fittings use seamless or welded pipe as the starting material and are formed (through multiple processes) to get the shape of elbows, tees and reducers etc. Just as the pipe is sold from Schedule 10 to Schedule 160, butt weld pipe fittings are sold the same way. Welded butt weld fittings are more common in stainless steel due to cost advantage. Sch 10 fittings are also more common in stainless steel butt weld fittings.Common material for butt weld fittings are A234 WPB (A & C also available), High Yield Carbon Steel, Stainless Steel 304 and 316 and Nickel Alloys.

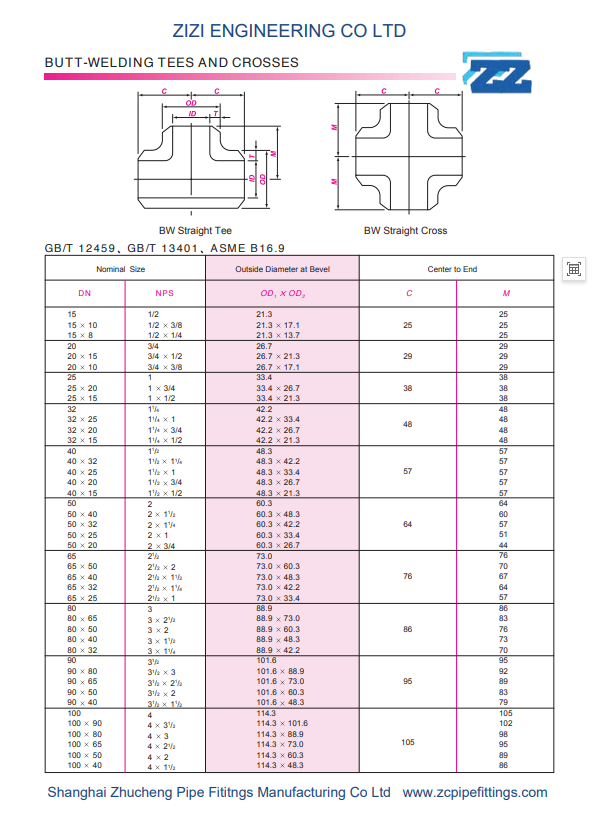

| Shape | Elbow, Tee, Cross, Bend, Reducer, Cap, Stub End |

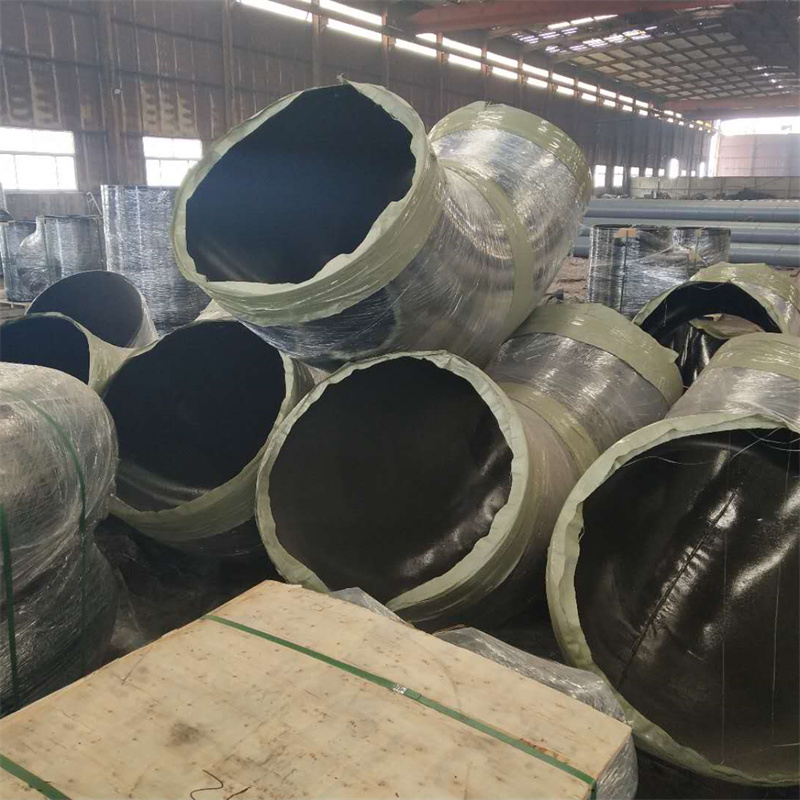

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10,SCH 10S, SCH 20, SCH 40,SCH 40S, STD, XS,SCH 80, SCH 80S, SCH 100, SCH 120, SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| apan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 321, 317,347,904L |

| Duplex Stainless Steel | ASTM A815 S32205, S31803, 32750, 32760 |

Types of Butt Weld Pipe Fittings

Welded pipe fittings in carbon steel and stainless steel are the joining components that make possible the assembly of valves, pipes and equipment onto the piping system. Welded fittings compliment pipe flanges in any piping system and allows:

Change direction of flow in a piping system

Connect or joint pipes and equipment

Provide branches, access and takeoffs for auxiliary equipment

A common example using welded pipe fitting is a pipe reduced by concentric reducer, welded to a weld neck flange and connected to equipment. The figure below represents a complete collection of butt welded pipe fittings.

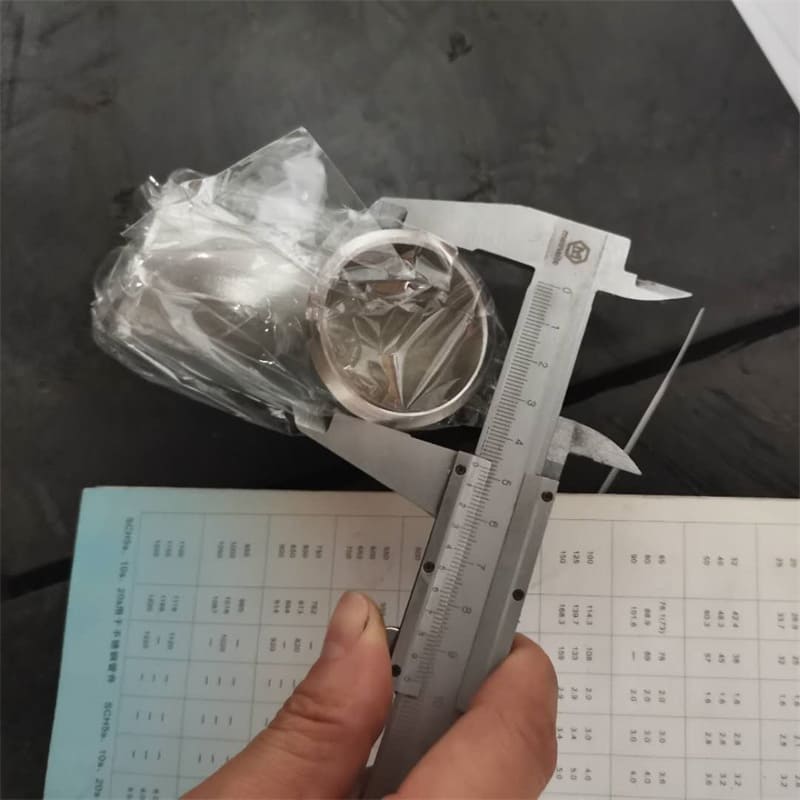

Buttweld Pipe Fitting Specification & Standards

Welded pipe fittings are made as per ASME spec B16.9. ASME B16.9 covers factory made wrought steel butwelding fittings in sizes 1/2″ to 48″. This standard however does not cover low pressure corrosion resistant buttwelding fittings. See MSS SP-43, Wrought Stainless Steel Butt-Welding Fittings.

Common Materials for Welded Pipe Fittings

Carbon Steel Welded Fitting:

A234 WPB is the most common material used for carbon steel butt welded fittings.

ASTM A234 WPB is the Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service.

Specifications

ASTM: A234 WPB

ASME: B16.9, B.11

NACE: MRO175

MSS: SP-83, SP-95

Welded connection offers a more robust connection

Continuous metal structure adds to the strength of the piping system

Buttweld fittings with matching pipe schedules, offers seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting

Option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

Cost effective compared to their expensive threaded or socket weld counter parts

Stainless Steel Welded Fittings are also available in SCH 10, allowing a more thinner wall option

Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration