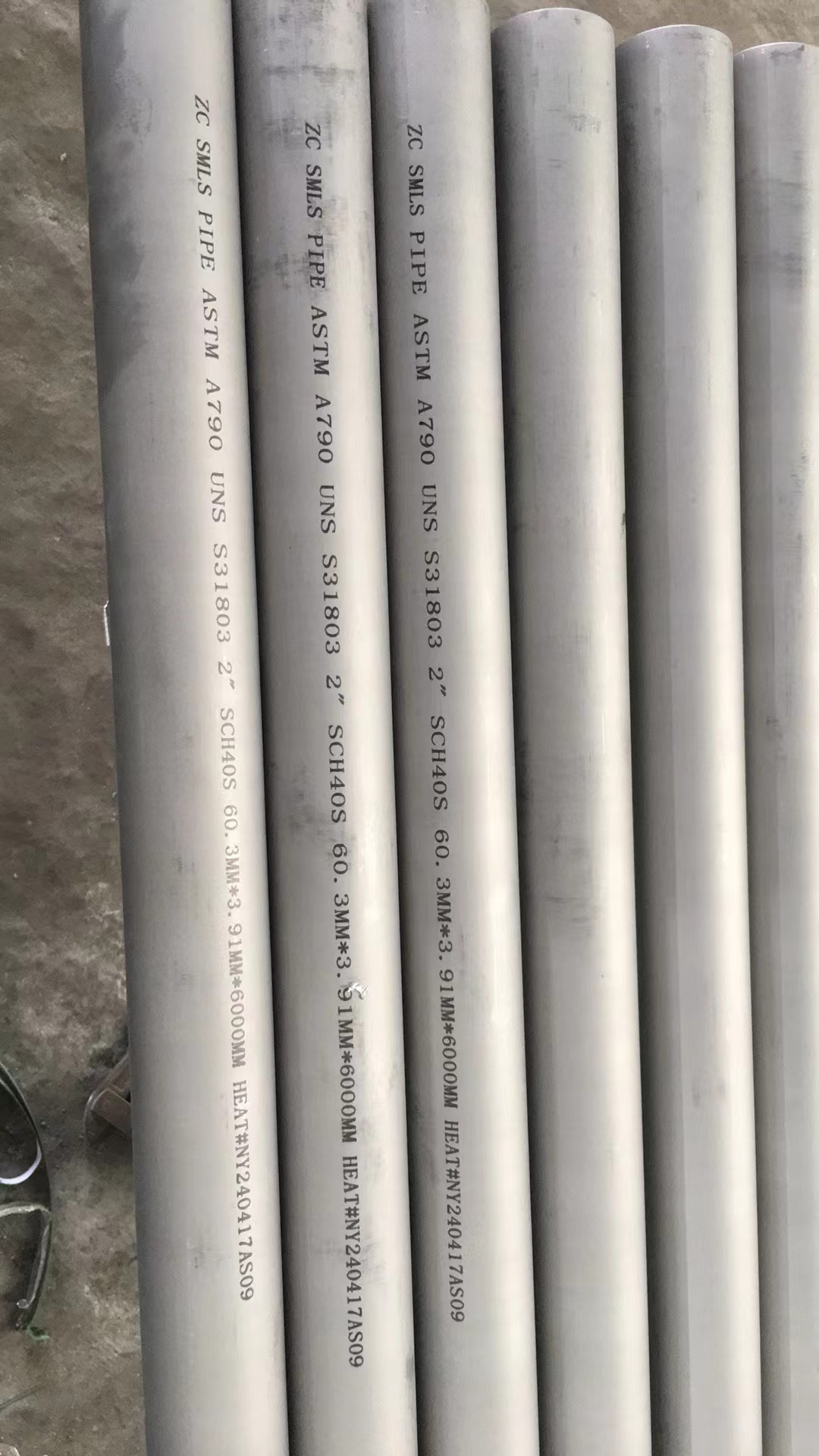

ASTM A790 S31803 Steel Pipe

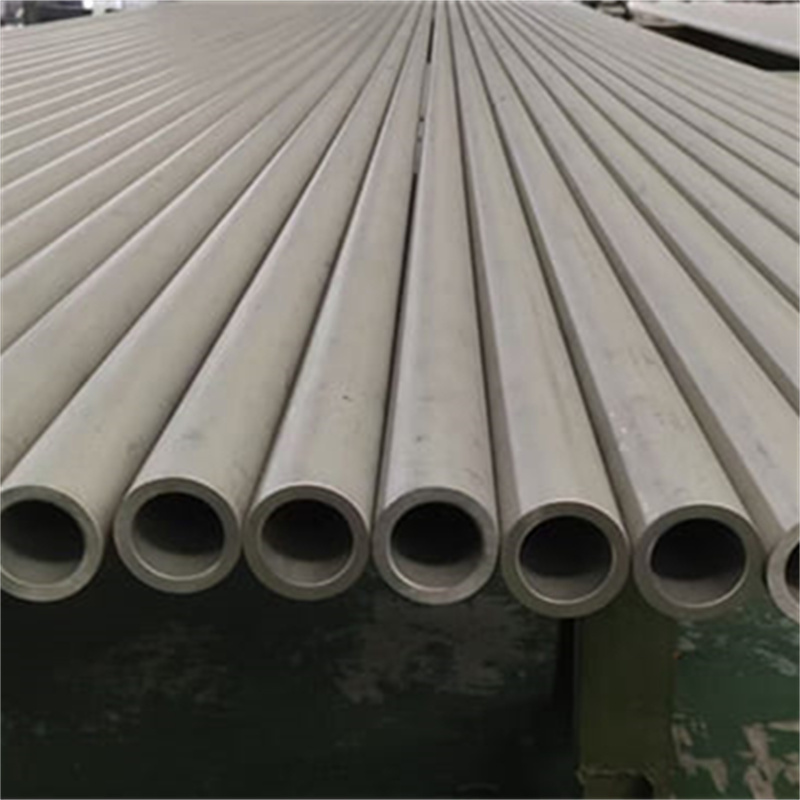

ASTM A790 S31803 steel pipe is a special type of stainless steel pipe, whose microstructure is mainly composed of austenite and ferrite.

ASTM A790 S31803 steel pipe is a special type of stainless steel pipe, whose microstructure is mainly composed of austenite and ferrite. The austenite phase provides good toughness, corrosion resistance, high strength and good processability, while the ferrite phase enhances the steel’s resistance to stress corrosion cracking, thermal conductivity and resistance to chloride stress corrosion cracking. Therefore, duplex stainless steel pipes usually have the characteristics of high strength, good corrosion resistance, excellent welding performance and high thermal conductivity.

Duplex stainless steel pipes also have a lower linear expansion coefficient, which gives it better dimensional stability at high temperatures. These characteristics make duplex stainless steel pipes widely used in petroleum, chemical, seawater desalination, papermaking, and many other industrial fields.

Specifications of Duplex Stainless Steel Pipe

| Processing Method | Seamless and Welded |

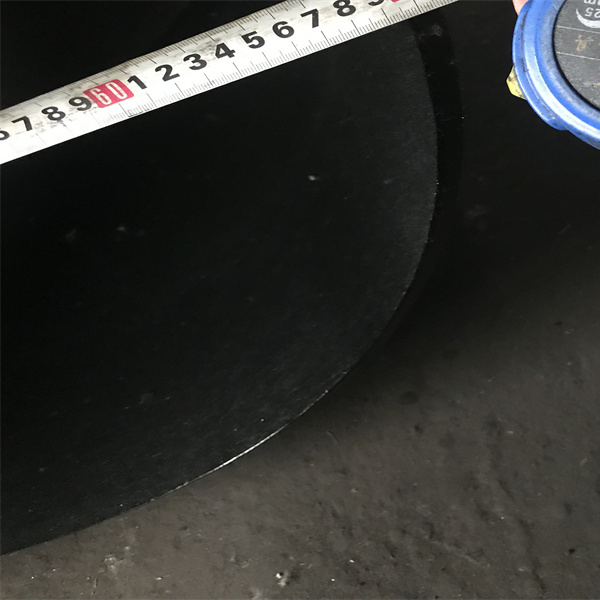

| Size Range | 1/8” – 30” / DN6 – 750 |

| Thickness Schedule | SCH 10S- SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.19 |

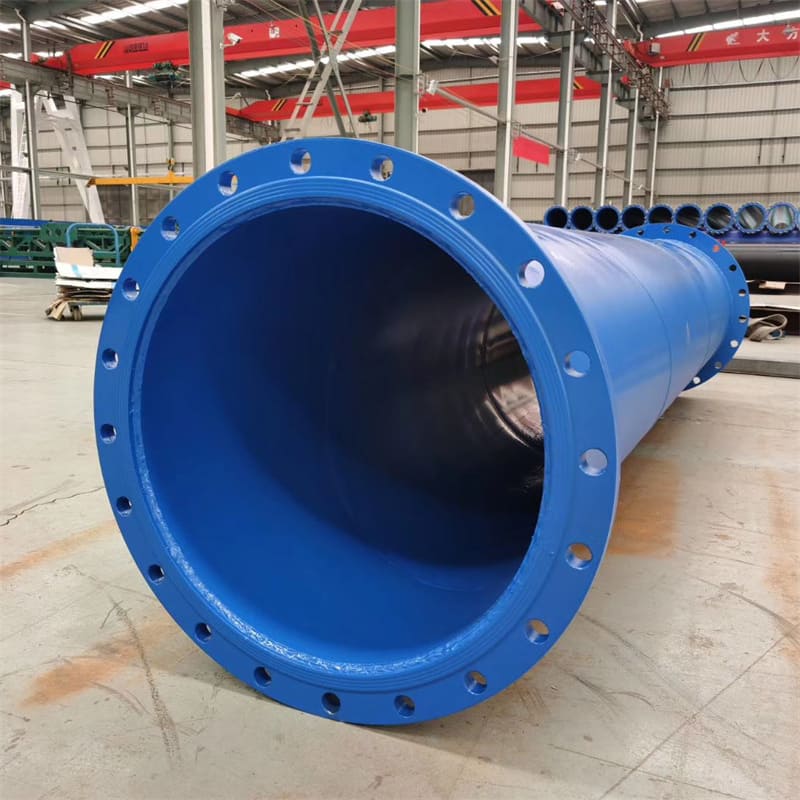

| Surface Treatment | Polish , Mirror , Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A312 TP304/304L/304H, 316/316L, 310S, 317, 347, 904L, S32205, S31803, 32750, 32760, S32550 |

ASME B36.19 Duplex Stainless Steel Pipe Dimensions

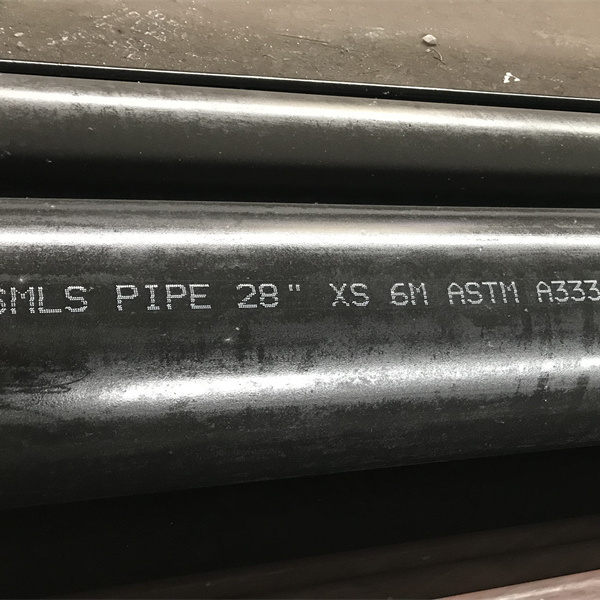

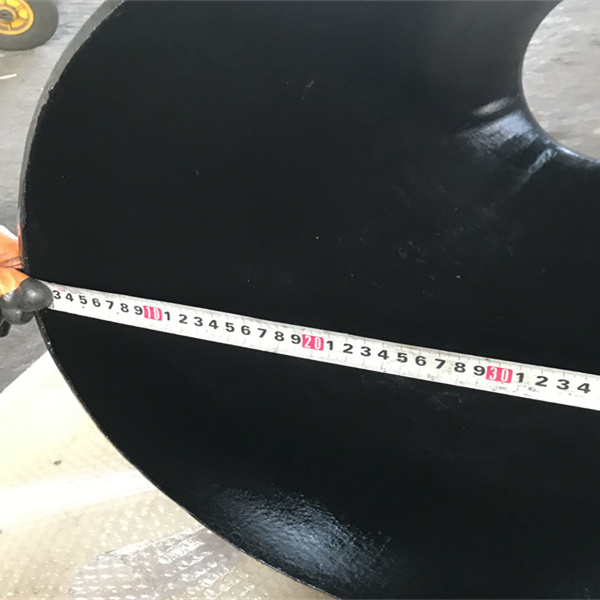

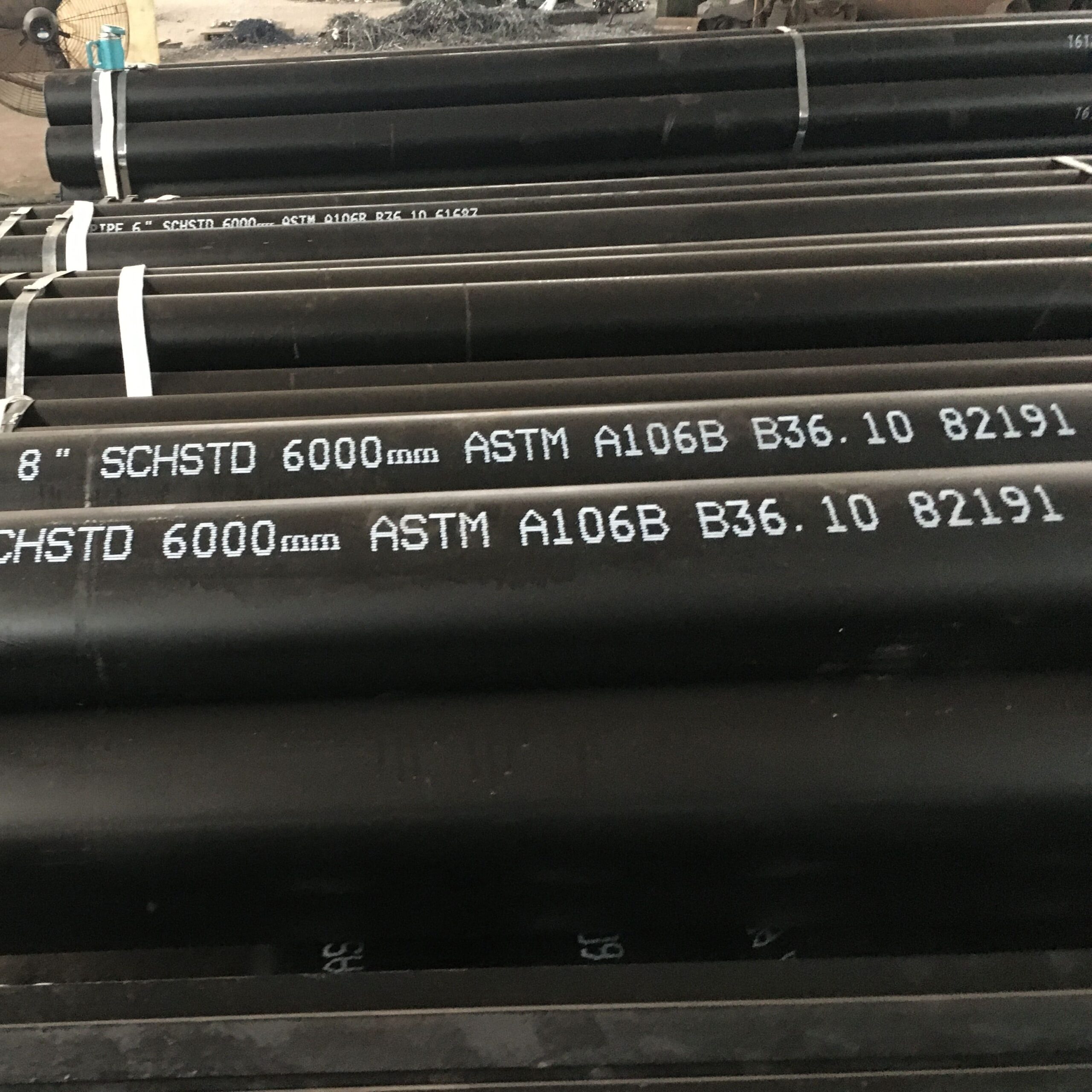

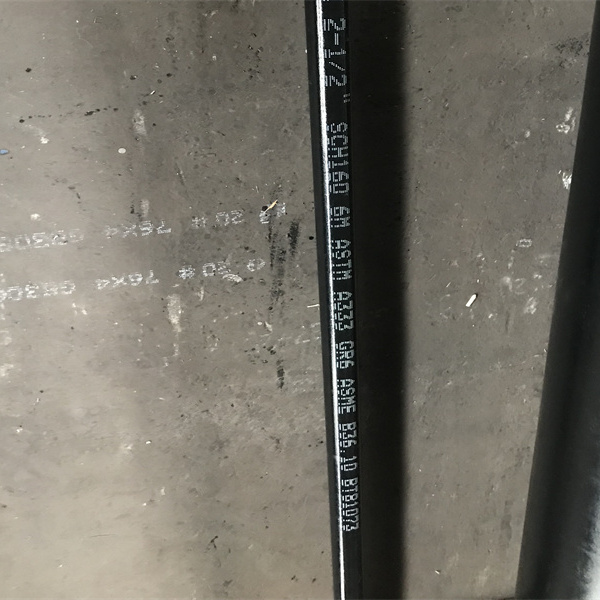

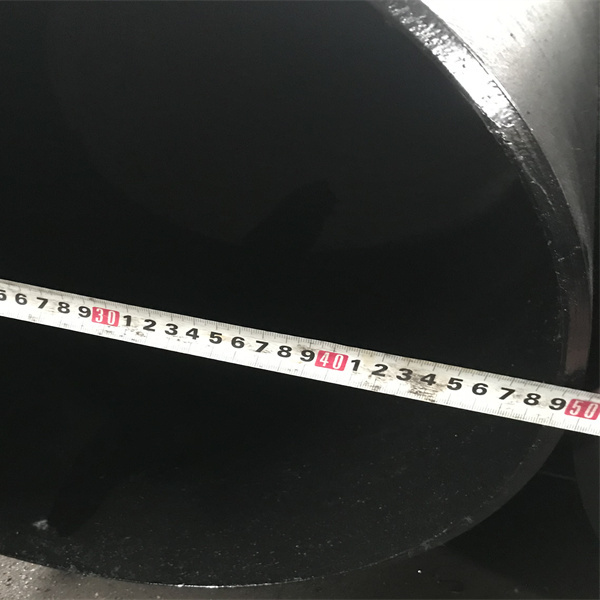

ASTM A790 S31803 steel pipe specifications are mainly applicable to sizes ranging from 1/8” to 30” (DN6 to DN750). The wall thickness of these steel pipes must comply with the ASME B36.19 standard, and the wall thickness grades are SCH 10, SCH 20, SCH 40, STD, XS, SCH 100, SCH 120, SCH 160, XXS.

| Stainless Steel Pipe (ASME B 36.19M) | ||||||||||

| Nominal Size | OD | Sch5s | Sch10s | Sch40s | Sch80s | |||||

| DN | NPS | 0 | T | kg/m | T | kg/m | T | kg/m | T | kg/m |

| 6 | 1/8 | 10.3 | 1.24 | 0.28 | 1.73 | 0.37 | 2.41 | 0.47 | ||

| 8 | 1/4 | 13.7 | 1.65 | 0.49 | 2.24 | 0.63 | 3.02 | 0.8 | ||

| 10 | 3/8 | 17.1 | 1.65 | 0.63 | 2.31 | 0.84 | 3.2 | 1.1 | ||

| 15 | 1/2 | 21.3 | 1.65 | 0.82 | 2.11 | 1 | 2.77 | 1.27 | 3.73 | 1.62 |

| 20 | 3/4 | 26.7 | 1.65 | 1.04 | 2.11 | 1.28 | 2.87 | 1.69 | 3.91 | 2.2 |

| 25 | 1 | 33.4 | 1.65 | 1.33 | 2.77 | 2.09 | 3.38 | 2.5 | 4.55 | 3.24 |

| 32 | 1 1/4 | 42.2 | 1.65 | 1.68 | 2.77 | 2.7 | 3.56 | 3.39 | 4.85 | 4.47 |

| 40 | 1 1/2 | 48.3 | 1.65 | 1.95 | 2.77 | 3.11 | 3.68 | 4.05 | 5.08 | 5.41 |

| 50 | 2 | 60.3 | 1.65 | 2.44 | 2.77 | 3.93 | 3.91 | 5.44 | 5.54 | 7.48 |

| 65 | 2 1/2 | 73.0 | 2.11 | 3.77 | 3.05 | 5.26 | 5.16 | 8.63 | 7.01 | 11.41 |

| 80 | 3 | 88.9 | 2.11 | 4.6 | 3.05 | 6.45 | 5.49 | 11.29 | 7.62 | 15.27 |

| 90 | 31/2 | 101.6 | 2.11 | 5.29 | 3.05 | 7.4 | 5.74 | 13.57 | 8.08 | 18.63 |

| 100 | 4 | 114.3 | 2.11 | 5.96 | 3.05 | 8.36 | 6.02 | 16.07 | 8.56 | 22.32 |

| 125 | 5 | 141.3 | 2.77 | 9.67 | 3.4 | 11.57 | 6.55 | 21.77 | 9.53 | 30.97 |

| 150 | 6 | 168.3 | 2.77 | 11.55 | 3.4 | 13.48 | 7.11 | 28.26 | 10.97 | 42.56 |

| 200 | 8 | 219.1 | 2.77 | 15.09 | 3.76 | 19.96 | 8.18 | 42.55 | 12.7 | 64.64 |

| 250 | 10 | 273.1 | 3.4 | 23.08 | 4.19 | 27.78 | 9.27 | 60.31 | 12.7 | 96.01 |

| 300 | 12 | 323.9 | 3.96 | 31.89 | 4.57 | 36 | 9.53 | 73.88 | 12.7 | 132.08 |

| 350 | 14 | 355.6 | 3.96 | 35.06 | 4.78 | 41.3 | ||||

| 400 | 16 | 406.4 | 4.19 | 42.41 | 4.78 | 47.29 | ||||

| 450 | 18 | 457.2 | 4.19 | 47.77 | 4.78 | 53.26 | ||||

| 500 | 20 | 508 | 4.78 | 60.46 | 5.54 | 68.61 | ||||

| 550 | 22 | 558.8 | 4.78 | 66.57 | 5.54 | 75.53 | ||||

| 600 | 24 | 609.6 | 5.54 | 84.16 | 6.35 | 94.45 | ||||

| 750 | 30 | 762 | 6.35 | 120.72 | 7.92 | 147.36 | ||||

Application fields

Oil and gas industry

Used for oil well pipes, oil pipelines and natural gas pipelines. In deep-sea oil production, ASTM A790 S31803 steel pipes can withstand the erosion of high-pressure, high-salinity seawater and corrosive media such as hydrogen sulfide, ensuring the safe transportation of oil and natural gas.

Chemical industry

In chemical plants, it is used to transport various corrosive chemicals such as acids, alkalis, and salt solutions. For example, in the chlor-alkali industry, duplex stainless steel pipes can be used to transport corrosive media such as chlorine-containing brine and sodium hydroxide solution.

Marine engineering

Duplex stainless steel pipes are widely used in offshore platform structural parts, seawater cooling system pipelines, seawater desalination equipment, etc. Due to its excellent seawater corrosion resistance and high strength, it can improve the service life and reliability of marine engineering facilities.