What is a pipe bend ?

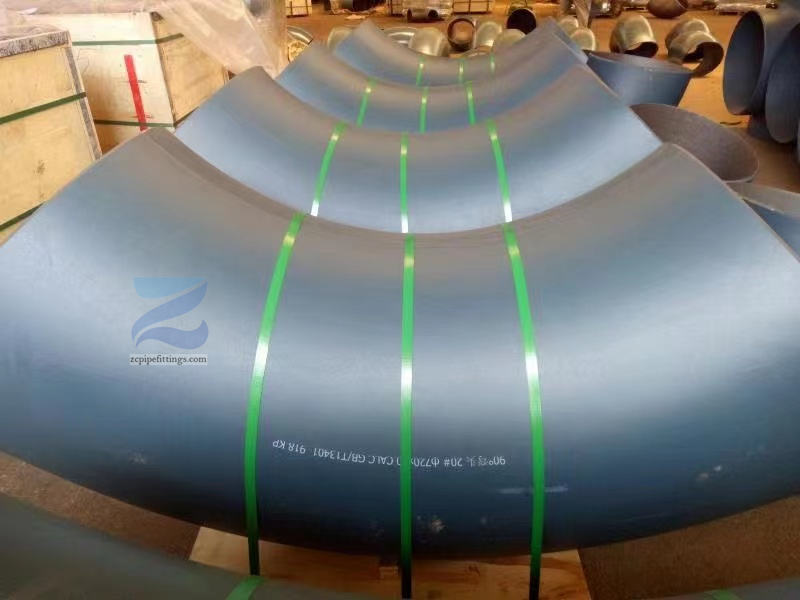

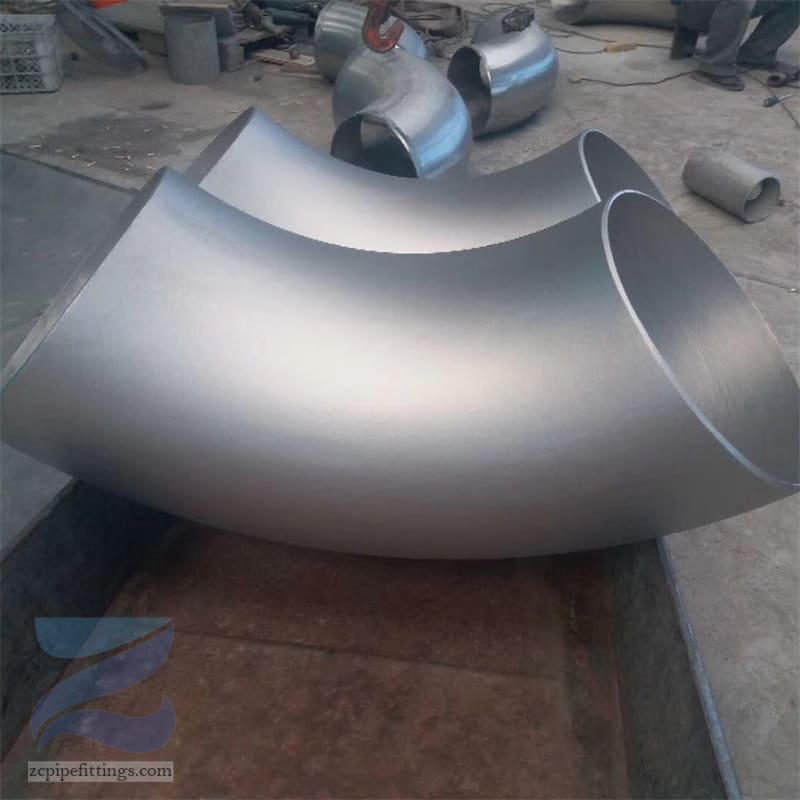

A pipe bend is the generic term for what is called in piping as an “offset” – a change in direction of the piping. A bend is usually meant to mean nothing more than that there is a “bend”– a change in direction of the piping (usually for some specific reason) – but it lacks specific, engineering definition as to direction and degree. Bends are usually custom-made (using a bending machine) on site and suited for a specific need.

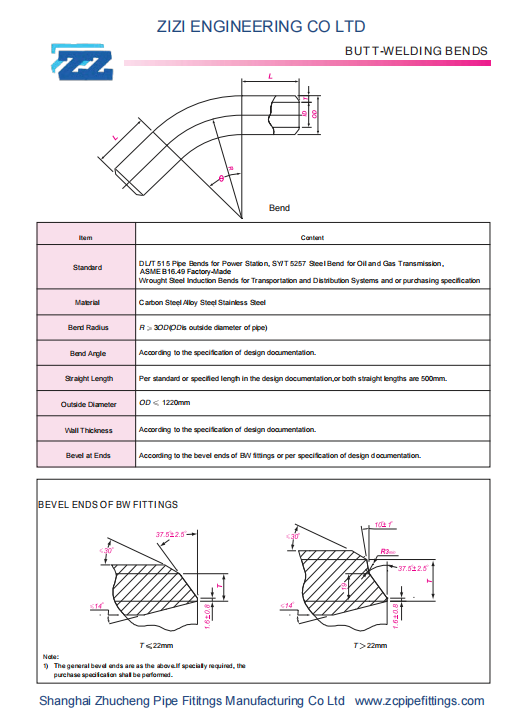

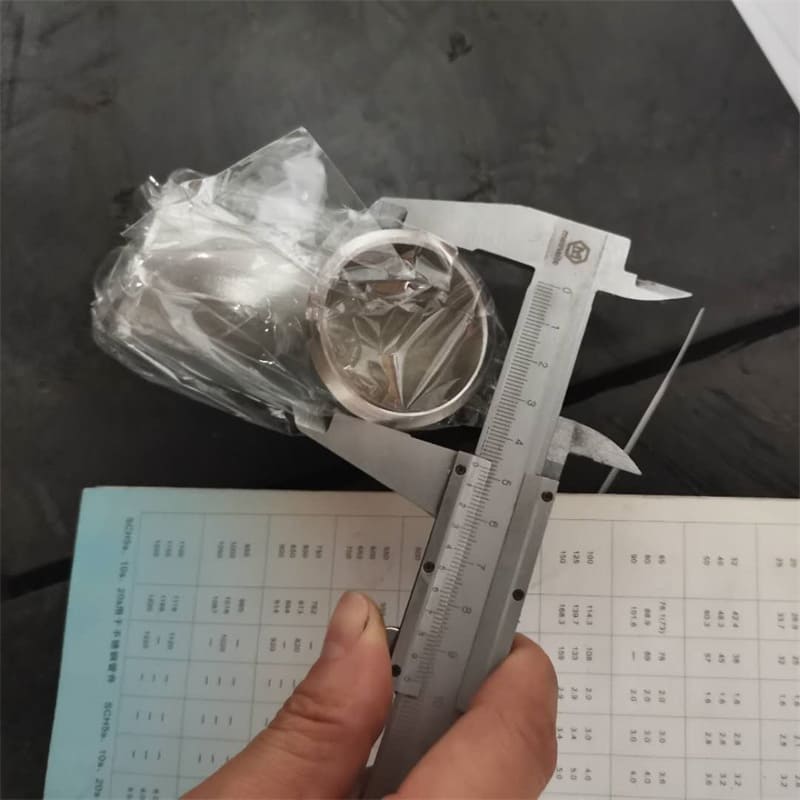

Dimension of pipe bend

| Type | 90 Degree and 45 Degree |

| Size Range | 1/2″ – 48″ / DN15 – 1200 |

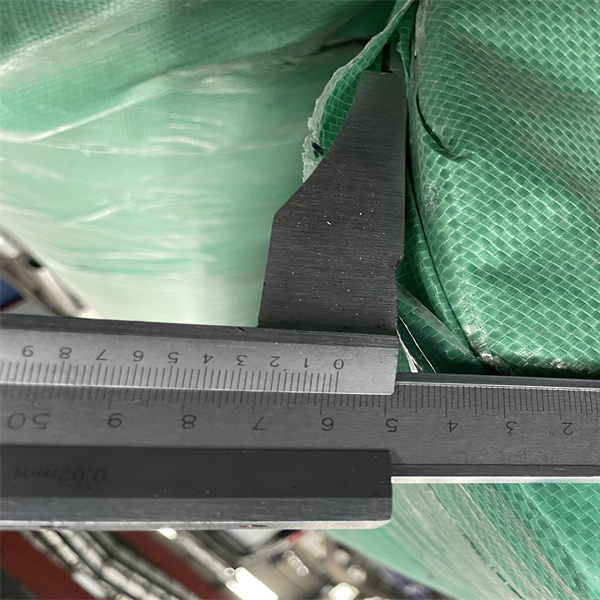

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Bending Radius | R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D) |

| Straight Length | The length of both ends is generally 300-1500MM |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Germany Standard | DIN2605/2615/2616/2617 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC, Galvanized |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

Difference between pipe bend and elbows

Pipe bends typically have a minimum bending radius of 1.5 times pipe radius (R). If this bending radius is less than 1.5R, it is called Elbow. Reference to any international / industry standard need to be traced. 1.5, 3 and 4.5 R are the most common bending radii in industry.

A pipe bend typically flows smoother since there are not irregular surfaces on the inside of the pipe, nor does the fluid have to change direction abruptly.

The most basic difference of them is the elbow relatively short than bend, R = 1D to 2 D is elbow More than 2D is bend. In the production process, cold bends can use Bending Machine to bend by ready-made straight bend. One-time completed also don’t need second corrosion. But elbow need manufacturers make to order, to do anti-corrosion, order cycle is long. Elbow price is higher than bend. But cost performance is much higher than bend. It is well-known that bend do not have anticorrosive processing is easy damaged, but the price is cheap so are used very much in some demand which not very high engineering.