ASTM A403 WP304 Concentric Reducer

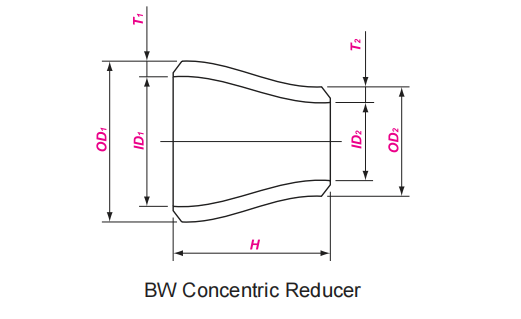

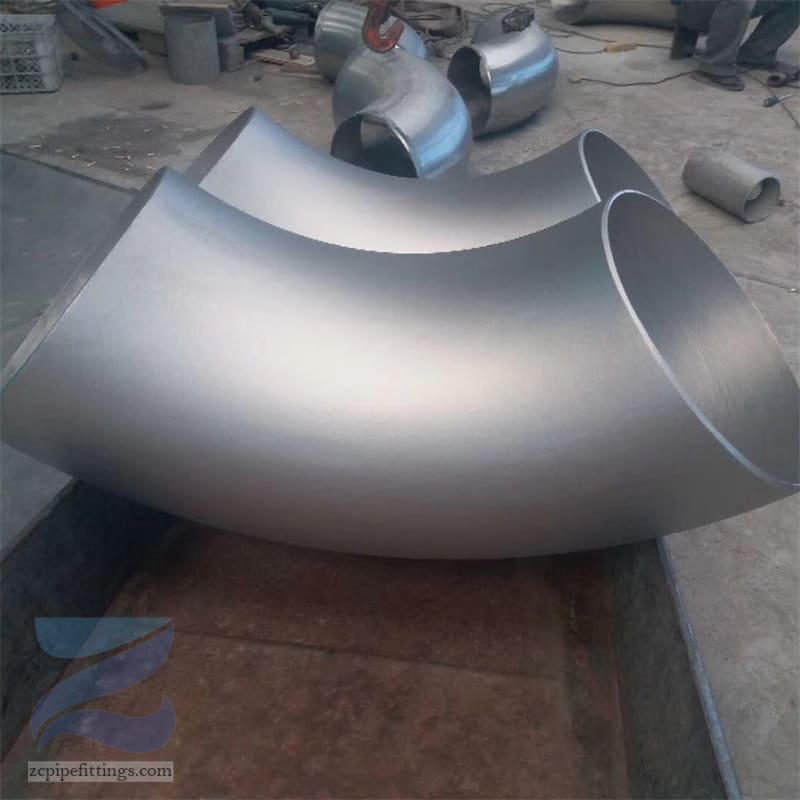

The characteristic of concentric reducers is that their center lines coincide, that is, the centers of the large and small heads are on the same straight line. This design allows the flow direction of the fluid to remain basically unchanged when passing through the reducer, reducing the resistance caused by the change in flow direction.

The characteristic of concentric reducers is that their center lines coincide, that is, the centers of the large and small heads are on the same straight line. This design allows the flow direction of the fluid to remain basically unchanged when passing through the reducer, reducing the resistance caused by the change in flow direction. Stainless steel has good corrosion resistance, which makes stainless steel concentric reducers suitable for a variety of corrosive environments. Common stainless steel materials such as 304 stainless steel contain alloy elements such as chromium (Cr) and nickel (Ni). The chromium element can form a dense chromium oxide protective film on the surface of stainless steel to prevent erosion by external corrosive media.

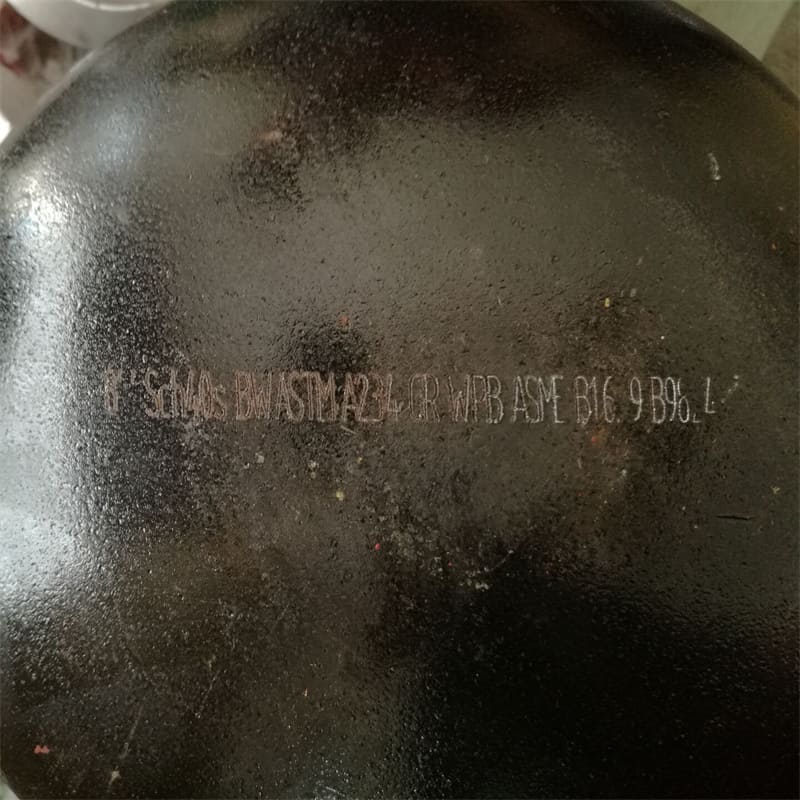

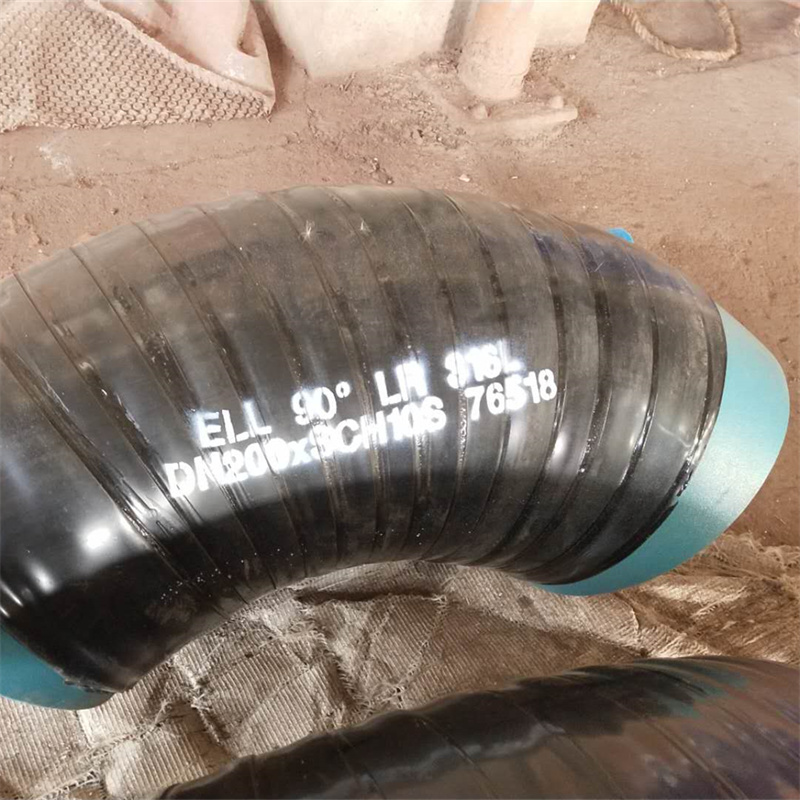

ASTM A403 WP304 Concentric Reducer Specification

| Size Range | 3/4″ – 60″ / DN20 – 1500 |

| Thickness Schedule | SCH 10 – SCH 80, SCH 160, XXS |

| America Standard | ANSI / ASME B16.9 |

| Japan Standard | JIS B2311/2312/2313 |

| Germany Standard | DIN2605/2615/2616/2617 |

| Europe Standard | EN10253 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

ASME B16.9 Concentric Reducer Dimensions & Sch 40 Weight