ASTM A350 LF2 Threaded Flange

ASTM A350 LF2 is a low temperature carbon steel material, mainly used to manufacture flanges and other connectors. This material has good low temperature performance and corrosion resistance, and is suitable for use in low or ultra-low temperature environments.

ASTM A350 LF2 is a low temperature carbon steel material, mainly used to manufacture flanges and other connectors. This material has good low temperature performance and corrosion resistance, and is suitable for use in low or ultra-low temperature environments.

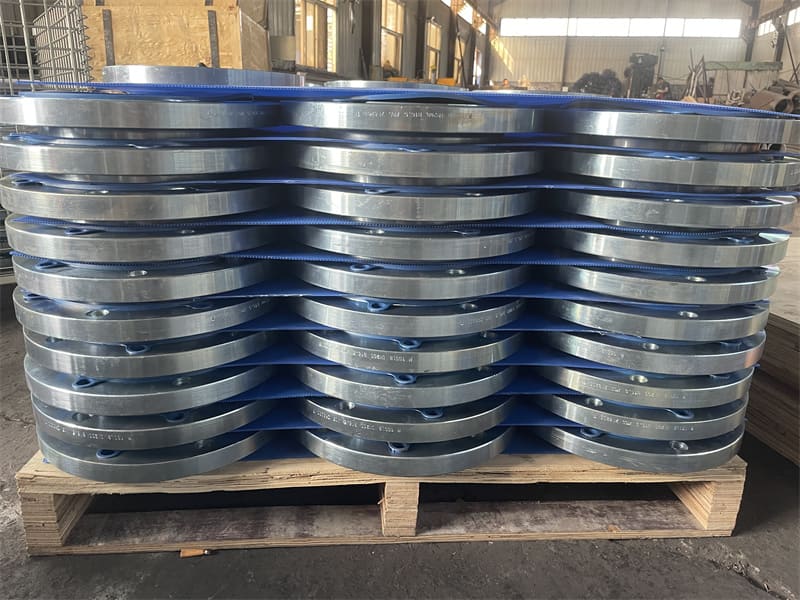

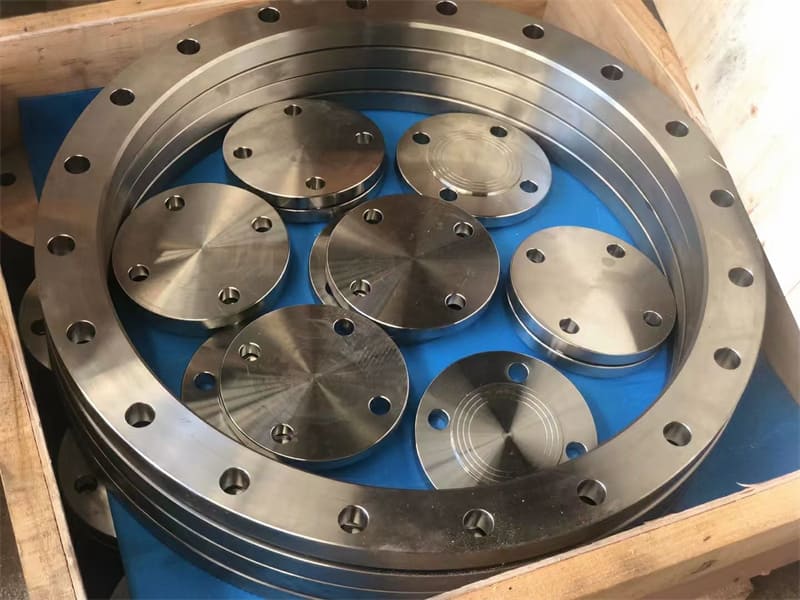

Threaded flanges are widely used in pipeline systems in the fields of petroleum, chemical industry, natural gas, water treatment, construction and machinery. They can be used to connect pipes, valves, pumps and other pipeline equipment to ensure the integrity and sealing of the pipeline system.

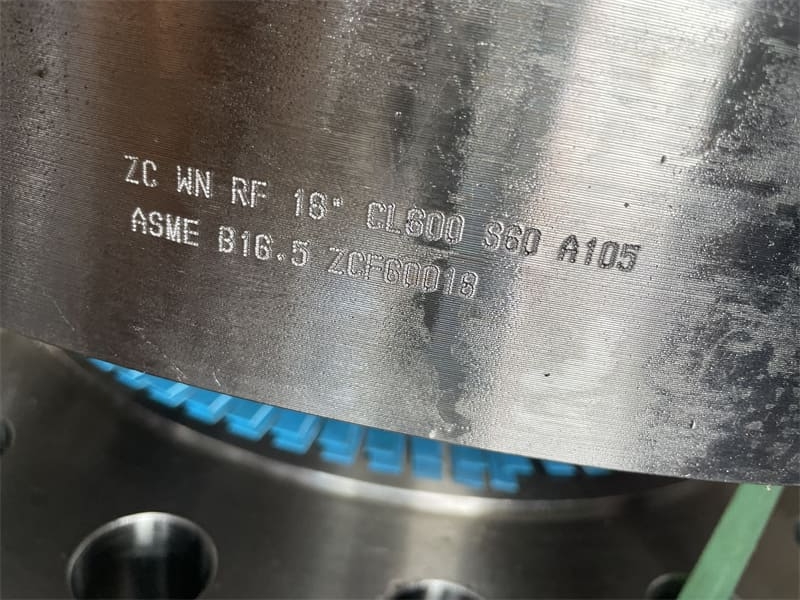

Specification of ASTM A350 LF2 Threaded Flange

| Size Range | 1/2″ – 24″ / DN15 – DN600 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ASME B16.5, EN1092-1 |

| Low Temp Carbon Steel | ASTM A350 LF2/LF3 |

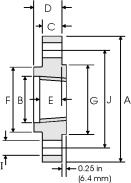

Dimension of ASTM A350 LF2 Threaded Flange

Class 900 lb Threaded Flange Dimensions & Weight

| Nominal Pipe Size |

A | B | C | D | E | F | G | H | I | J | Weight | |

| mm | mm | mm | mm | mm | mm | mm | mm | Holes | mm | mm | kg/ piece |

|

| 1/2 | 21.30 | 120.6 | 23.60 | 22.30 | 31.70 | 22.30 | 38.10 | 35.10 | 4 | 22.30 | 82.5 | 1.74 |

| 3/4 | 26.70 | 130.0 | 29.00 | 25.40 | 35.00 | 25.40 | 44.40 | 42.90 | 4 | 22.30 | 88.9 | 2.34 |

| 1 | 33.40 | 149.3 | 35.80 | 28.40 | 41.10 | 28.40 | 52.30 | 50.80 | 4 | 25.40 | 101.6 | 3.44 |

| 11/4 | 42.20 | 158.7 | 44.40 | 28.40 | 41.10 | 30.20 | 63.50 | 63.50 | 4 | 25.40 | 111.2 | 3.91 |

| 11/2 | 48.30 | 177.8 | 50.50 | 31.70 | 44.50 | 31.70 | 69.85 | 73.15 | 4 | 28.40 | 123.9 | 5.36 |

| 2 | 60.30 | 215.9 | 63.50 | 38.10 | 57.15 | 38.10 | 104.6 | 91.90 | 8 | 25.40 | 165. 1 | 9.85 |

| 21/2 | 73.00 | 244.3 | 76.20 | 41.10 | 63.50 | 47.70 | 123.9 | 104.6 | 8 | 28.40 | 190.5 | 13.7 |

| 3 | 88.90 | 241.3 | 92.20 | 38.10 | 53.80 | 41.10 | 127.0 | 127.0 | 8 | 25.40 | 190.5 | 11.6 |

| 4 | 114.3 | 292.1 | 117.6 | 44.40 | 69.85 | 47.80 | 158.7 | 157.2 | 8 | 31.70 | 234.9 | 19.7 |

| 5 | 141.3 | 349.2 | 144.5 | 50.80 | 79.25 | 53.80 | 190.5 | 185.7 | 8 | 35.00 | 279.4 | 31.9 |

| 6 | 168.3 | 381.0 | 171.4 | 55.60 | 85.80 | 57.15 | 234.9 | 215.9 | 12 | 31.70 | 317.5 | 41.1 |

| 8 | 219.1 | 469.9 | 222.2 | 63.50 | 101.6 | 63.50 | 298.4 | 269.7 | 12 | 38.10 | 393.7 | 70.7 |

| 10 | 273.0 | 546.1 | 276.3 | 69.85 | 107.9 | 71.40 | 368.3 | 323.9 | 16 | 38.10 | 469.9 | 101 |

| 12 | 323.8 | 609.6 | 328.7 | 79.40 | 117.3 | 76.20 | 419.1 | 381.0 | 20 | 38.10 | 533.4 | 133 |

| 14 | 355.6 | 641.3 | 360.4 | 85.70 | 130.0 | 82.50 | 450.8 | 412.7 | 20 | 41.10 | 558.8 | 153 |

| 16 | 406.4 | 704.8 | 411.2 | 88.90 | 133.3 | 85.90 | 508.0 | 469.9 | 20 | 44.40 | 618.9 | 185 |

| 18 | 457.2 | 787.4 | 462.0 | 101.6 | 152.4 | 88.90 | 565.1 | 533.4 | 20 | 50.80 | 685.8 | 258 |

| 20 | 508.0 | 857.2 | 512.8 | 107.9 | 158.7 | 91.90 | 622.3 | 584.2 | 20 | 53.80 | 749.3 | 317 |

| 24 | 609.6 | 1041.4 | 614.4 | 139.7 | 203.2 | 101.6 | 749.3 | 692.2 | 20 | 66.55 | 901.7 | 606 |

Advantages of ASTM A350 LF2 Threaded Flange

Excellent material: Threaded flanges are made of special materials such as low-temperature steel, which can maintain good stability and corrosion resistance in extremely low temperature environments, thereby ensuring long-term stable operation of the flange under low temperature conditions.

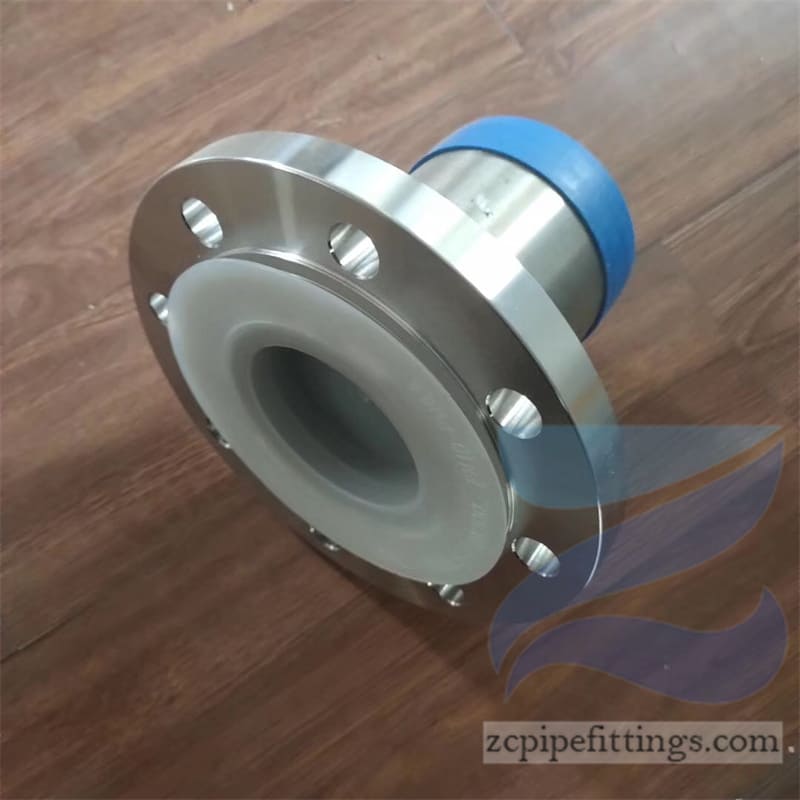

Excellent sealing performance: Its sealing surface design is unique, usually using a flange or corrugated structure. This design can still maintain excellent sealing performance under high pressure and low temperature environments, effectively preventing medium leakage.

Easy installation and maintenance: Threaded flanges are connected to pipelines through threads, without welding, and the installation and maintenance process is relatively simple, reducing construction difficulty and cost. At the same time, when the flange is deformed, the additional torque generated on the cylinder or pipeline is very small, which is conducive to protecting the stability of the pipeline system.

Wide range of applications: Low-temperature steel threaded flanges are suitable for a variety of low-temperature media, such as cryogenic liquids, gases, hydrogen and liquefied natural gas, etc., and can meet the needs of cryogenic flanges in different fields.

High strength and economy: Although the thickness of the threaded flange is relatively large, its strength is sufficient to meet the connection requirements of high-pressure pipelines. At the same time, under certain conditions, the economy of the threaded flange is also more prominent.