Home » Steel Pipes » ASTM A335 P91 Alloy Steel Pipe

ASTM A335 P91 Alloy Steel Pipe

ASTM A335 P91 is a standard specification for seamless ferritic alloy-steel pipes designed for high-temperature service.

Contact US

Get Price

Share:

Previous:

Inconel 601 Pipe

Next:

Monel 400 Material

Content

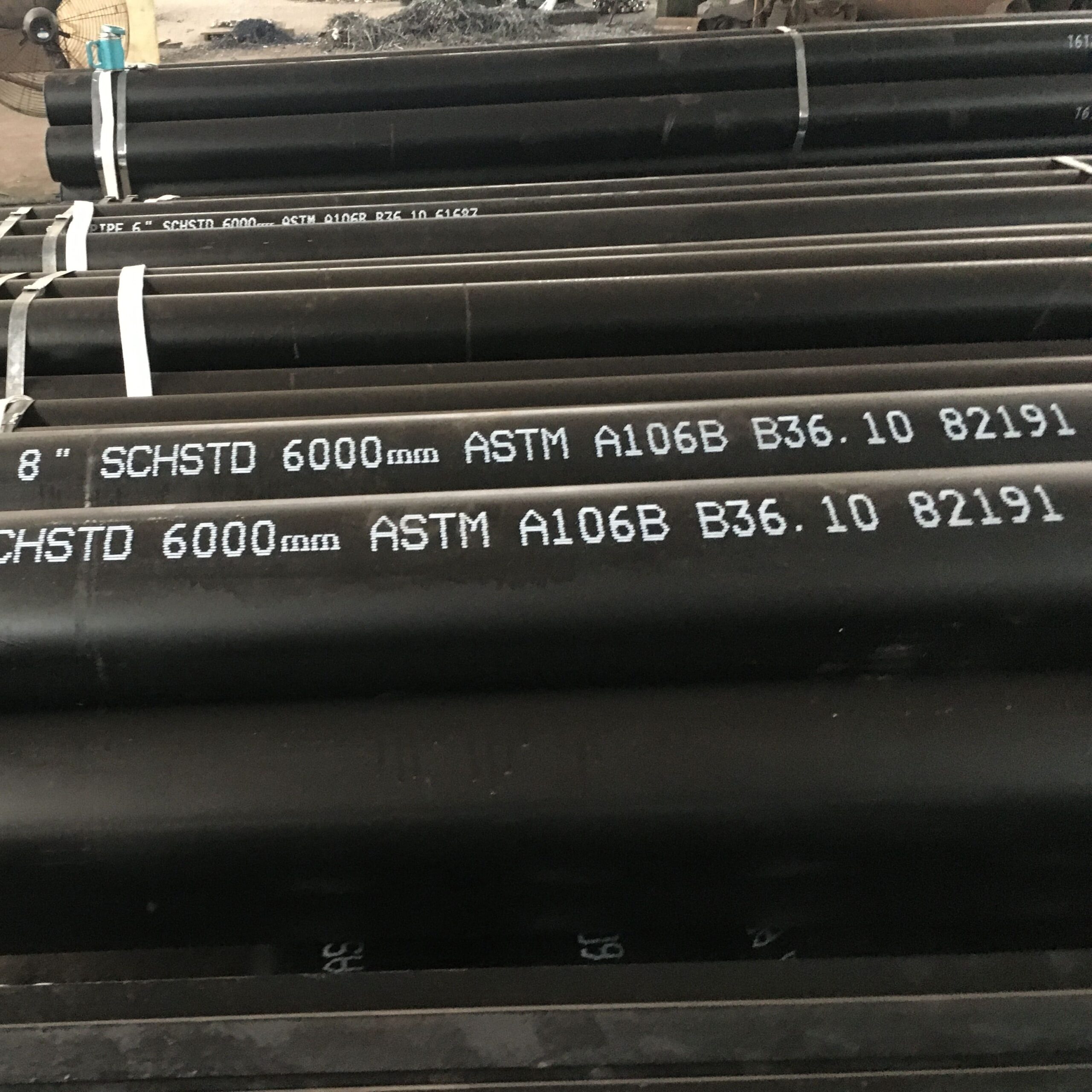

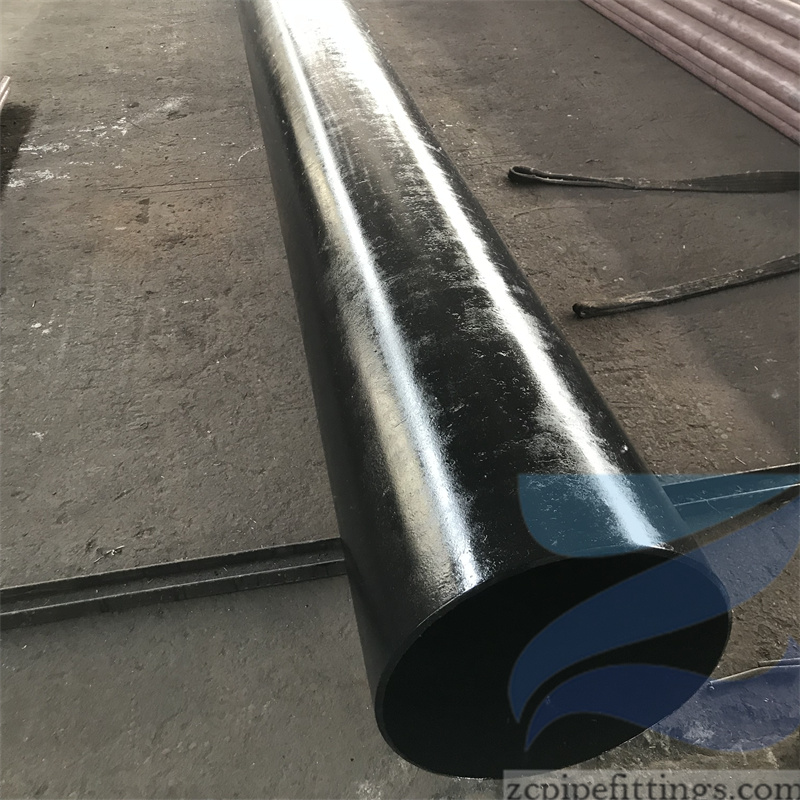

ASTM A335 P91 is a standard specification for seamless ferritic alloy-steel pipes designed for high-temperature service. P91 is a chromium-molybdenum alloy steel with added vanadium and niobium, which provides excellent high-temperature strength, oxidation resistance, and creep resistance. It is widely used in power plants, petrochemical industries, and other high-temperature applications.

ASTM A335 Alloy Steel Pipe Size & Grades

Inquiry

More Steel Pipes