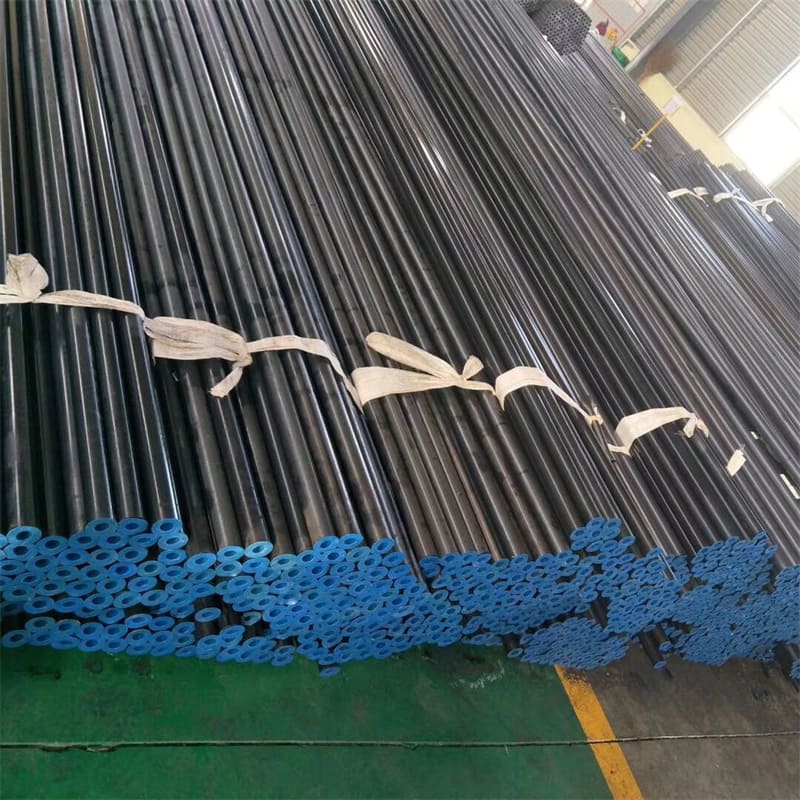

ASTM A335 Alloy Steel Pipe

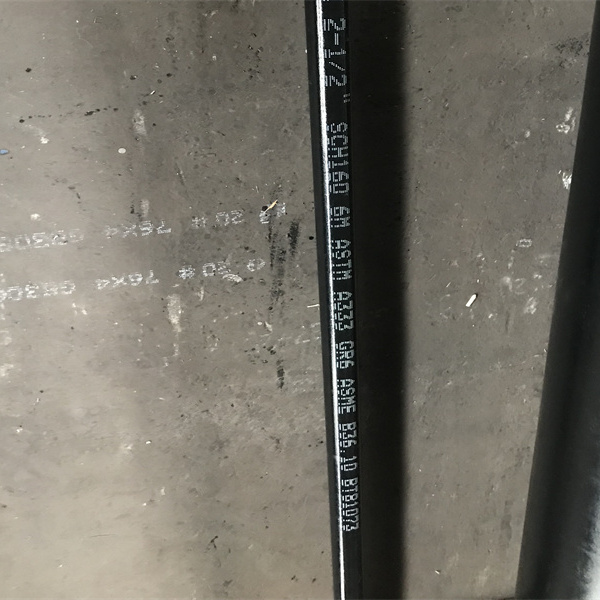

ASTM A335 alloy steel pipe is an alloy steel pipe produced in accordance with the A335 standard established by the American Society for Testing and Materials (ASTM).

ASTM A335 alloy steel pipe is an alloy steel pipe produced in accordance with the A335 standard established by the American Society for Testing and Materials (ASTM). This standard covers the specifications for seamless ferritic alloy steel pipes suitable for high temperature service. The ASTM A335 standard specifies a variety of ferritic steel grades, which generally do not exceed 10% chromium content and belong to the range of medium and low alloy steels. Different grades correspond to different chemical compositions to meet the needs under different working conditions.

ASTM A335 alloy steel pipe is widely used in high temperature piping systems in industries such as petroleum, chemical industry, and electric power due to its excellent high temperature resistance and good mechanical properties.

ASTM A335 Alloy Steel Pipe Specification

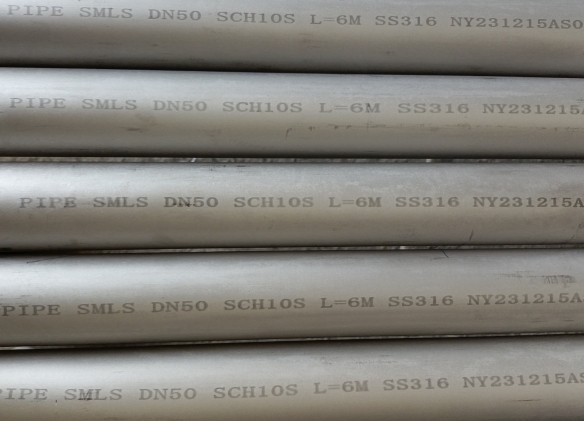

| Processing Method | Seamless and Welded |

| Size Range | 1/8” – 48” / DN6 – 1200 |

| Thickness Schedule | SCH 20- SCH 160, XXS |

| Length | 6m or 12 m or Random |

| Standard | ASME B36.10 |

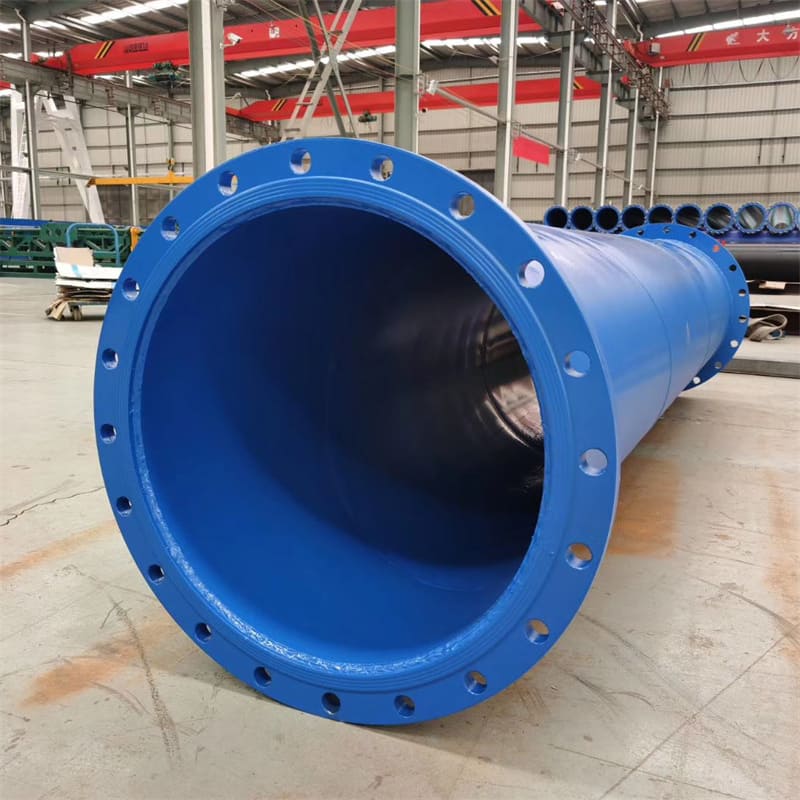

| Surface Treatment | Blasting and Painting, Epoxy Powder FBE, 2PE, 3PE Coating |

| Material Grade | ASTM A335 P11 / P12 / P 5 / P9 / P91 / P92, A213 T11 / T12 / T22 / T5 / T9 / T91 / T92. 15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

ASTM A335 Alloy Steel Pipe Chemical Composition

| Grade | P-5 | P-9 | P-11 | P-12 | P-22 | P-91 | P-91 shall also include the following: | |

| Element | UNS Designation | K41545 | S50400 | K11597 | K11562 | K21590 | K91560 | |

| Carbon | 0.15 max | 0.15 max | 0.05 – 0.15 | 0.05 – 0.15 | 0.05 – 0.15 | 0.08 – 0.12 | V at 0.18 – 0.25 | |

| Manganese | 0.30 – 0.60 | 0.30 – 0.60 | 0.30 – 0.60 | 0.30 – 0.61 | 0.30 – 0.60 | 0.30 – 0.60 | N at 0.030 – 0.070 | |

| Phosphorous, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.02 | Ni at 0.40 max | |

| Sulfur, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.01 | Al at 0.02 max | |

| Silicon | 0.50 max | 0.25 – 1.00 | 0.50 – 1.00 | 0.50 max | 0.50 max | 0.20 -0.50 | Cb at 0.06 – 0.10 | |

| Chromium | 4.00 – 6.00 | 8.00 – 10.00 | 1.00 – 1.50 | 0.80-1.25 | 1.90 – 2.60 | 8.00 – 9.50 | Ti at 0.01 max | |

| Molybdenum | 0.45 -0.65 | 0.90 – 1.10 | 0.44 – 0.65 | 0.44-0.65 | 0.87 – 1.13 | 0.85 – 1.05 | Zr at 0.01 max | |

Tensile Requirements of Alloy Steel Seamless Pipes

| Seamless | ||||||

| P-5 | P-9 | P-11 | P-12 | P-22 | P-91 | |

| Tensile Strength, min., psi | ||||||

| ksi | 60 | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min., psi | ||||||

| ksi | 30 | 30 | 30 | 32 | 30 | 60 |

| MPa | 205 | 205 | 205 | 220 | 205 | 415 |

Application fields of ASTM A335 Alloy Steel Pipe

ASTM A335 is a seamless ferritic alloy steel pipe standard specification in the American Society for Testing and Materials (ASTM) standard. This type of alloy pipe has good high temperature performance, oxidation resistance and creep resistance, so it is widely used in many fields:

Power industry

It is widely used in high temperature superheaters, reheaters and other parts of power station boilers. These parts need to withstand high temperature and high pressure steam environment. ASTM A335 alloy pipes can ensure structural stability during long-term operation with their excellent high temperature strength and oxidation resistance, ensuring safe and reliable operation of boilers.

Petrochemical industry

In the oil refining process, many process links involve high temperature, high pressure and corrosive media.

In the production equipment of chemical products such as synthetic ammonia and ethylene, ASTM A335 alloy pipes are used to transport high temperature and high pressure process gases and liquids. These process media may have corrosive or flammable and explosive characteristics. The excellent performance of the alloy pipe can ensure the safety and efficiency of the production process.

Coal chemical industry

During the coal gasification process, high temperature, high pressure and certain corrosive gas synthesis gas will be generated. ASTM A335 alloy pipes are used to transport synthesis gas and related high-temperature and high-pressure media. They can adapt to harsh working conditions and ensure the stable operation of coal gasification units.

In these complex coal chemical process units, the pipeline system needs to withstand a variety of complex working conditions. The comprehensive performance of ASTM A335 alloy pipes makes it an ideal choice for connecting various process equipment and transporting materials.