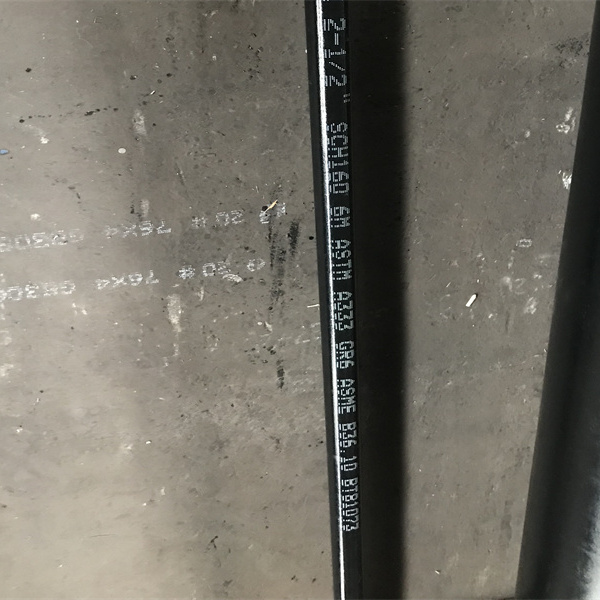

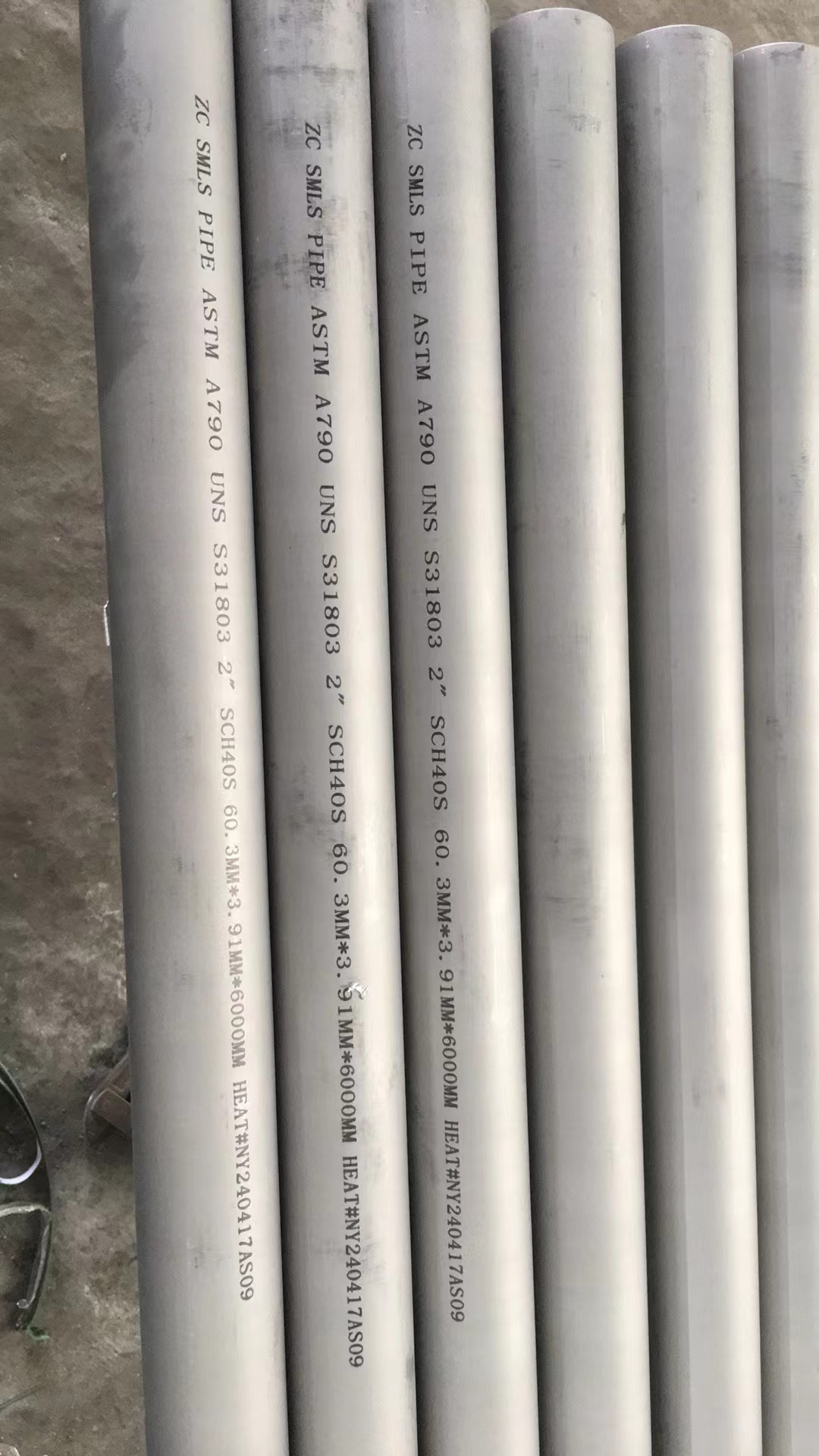

ASTM A312 S31254 Stainless Steel Pipe

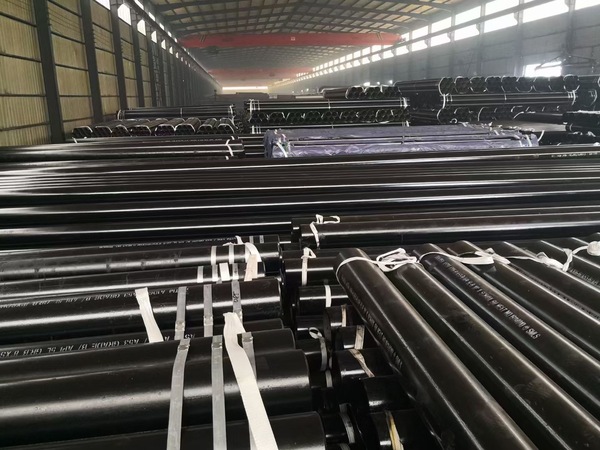

SMO 254 stainless steel pipe is a high-performance stainless steel material.It has unique chemical composition and excellent performance, maintaining excellent stability and durability.

SMO 254 stainless steel pipe is a high-performance stainless steel material.It has unique chemical composition and excellent performance, maintaining excellent stability and durability.Due to its excellent corrosion resistance, ASTM A312 S31254 stainless steel pipe is widely used in various corrosive media transportation pipelines, reactors, heat exchangers and other equipment in chemical production.

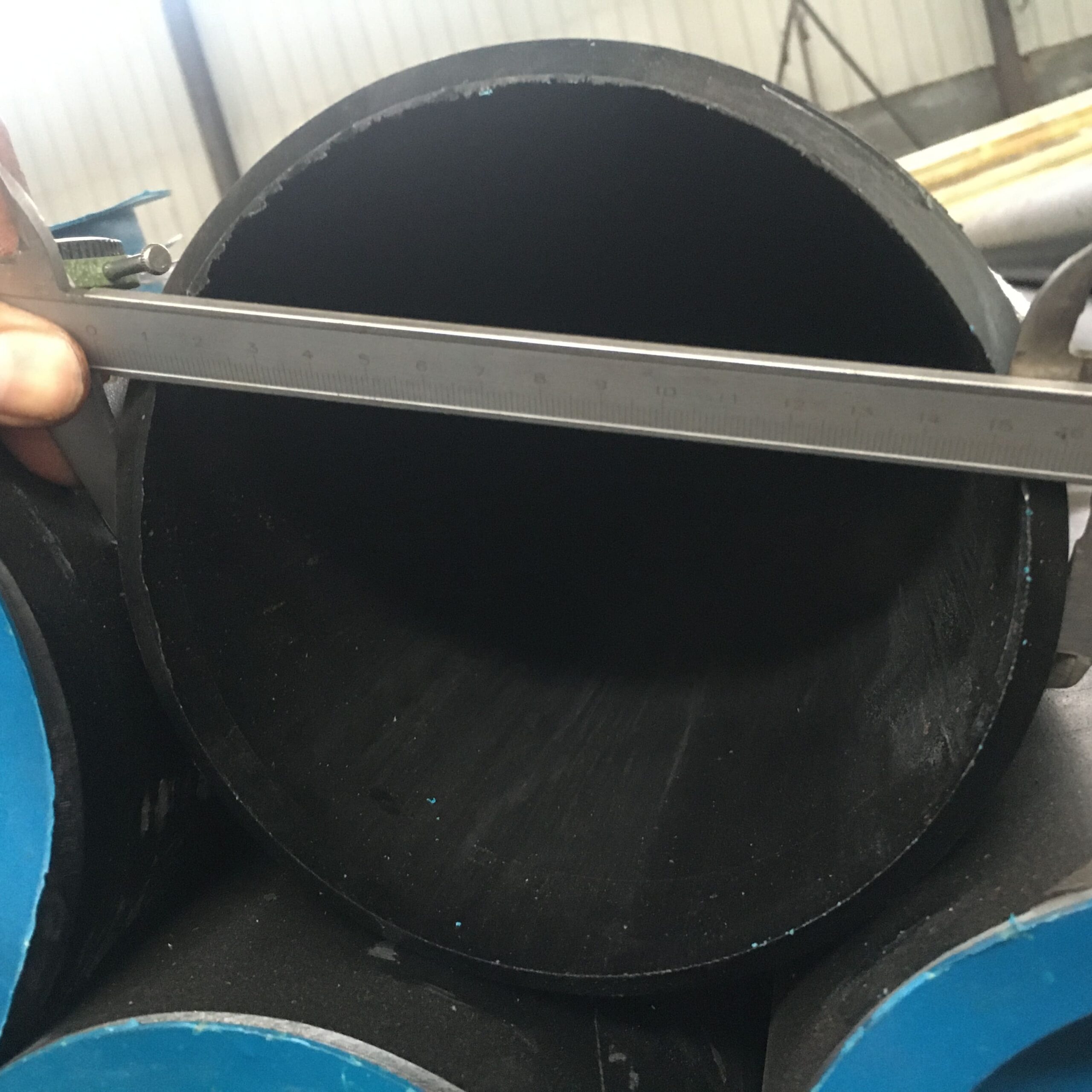

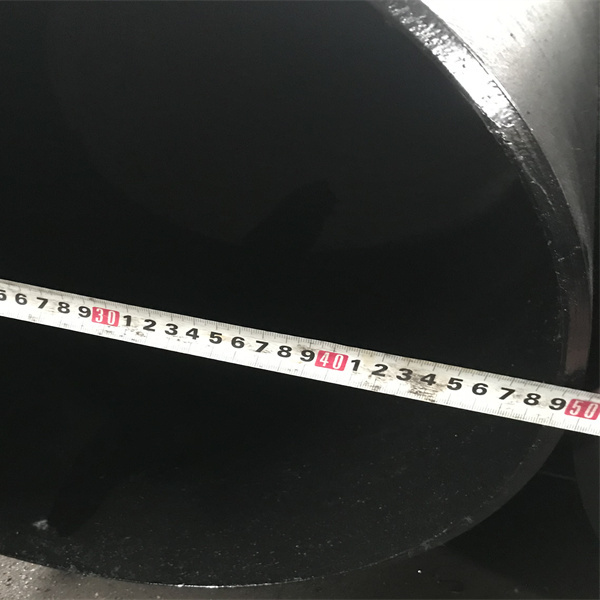

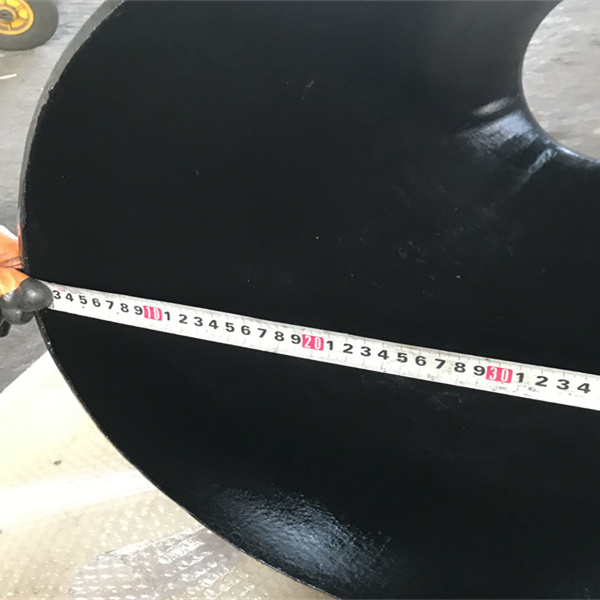

ASTM A312 is a standard specification for austenitic stainless steel pipes for seamless, welded and cryogenic applications developed by the American Society for Testing and Materials (ASTM). This standard covers the requirements for materials, manufacturing processes, dimensional tolerances, mechanical properties, chemical composition, inspection and testing of stainless steel pipes, aiming to ensure that the quality and performance of the steel pipes meet specific engineering and application requirements.

ASTM A312 S31254 Stainless Steel Pipe Material

Chemical Composition

Mechanical Properties

SMO 254 Stainless Steel Pipes and Tubes Physical Properties

| Specific Heat (0-100°C) | 500 | J.kg-1.°K-1 |

| Thermal Conductivity | 14 | W.m -1.°K-1 |

| Thermal Expansion | 16.5 | mm/m/°C |

| Modulus Elasticity | 196 | GPa |

| Electrical Resistivity | 8.5 | μohm/cm |

| Density | 8.0 | g/cm3 |

SMO 254 Stainless Steel Pipes Applications

- Saltwater handling

- Tall oil distillation columns

- Flue gas desulfurization scrubbers

- Components used in petroleum production

- Food processing equipment

- Process equipment in chemical industry

- Bleaching equipment in the pulp and paper industry

- Flue-gas cleaning

- Desalination

- Heat exchangers

- Equipment for handling of seawater, such as, seawater cooling, cooling water Pipes, ballast water systems, firefighting systems etc.

- Hydraulic and instrumention tubing

- Equipment in pulp bleaching plants

- Components in gas cleaning systems

- Tanks and pipelines for chemicals with high halide contents