What is a pipe bend?

A pipe bend is the generic term for what is called in piping as an “offset” – a change in direction of the piping. A bend is usually meant to mean nothing more than that there is a “bend” – a change in direction of the piping (usually for some specific reason) – but it lacks specific, engineering definition as to direction and degree. Bends are usually custom-made (using a bending machine) on site and suited for a specific need

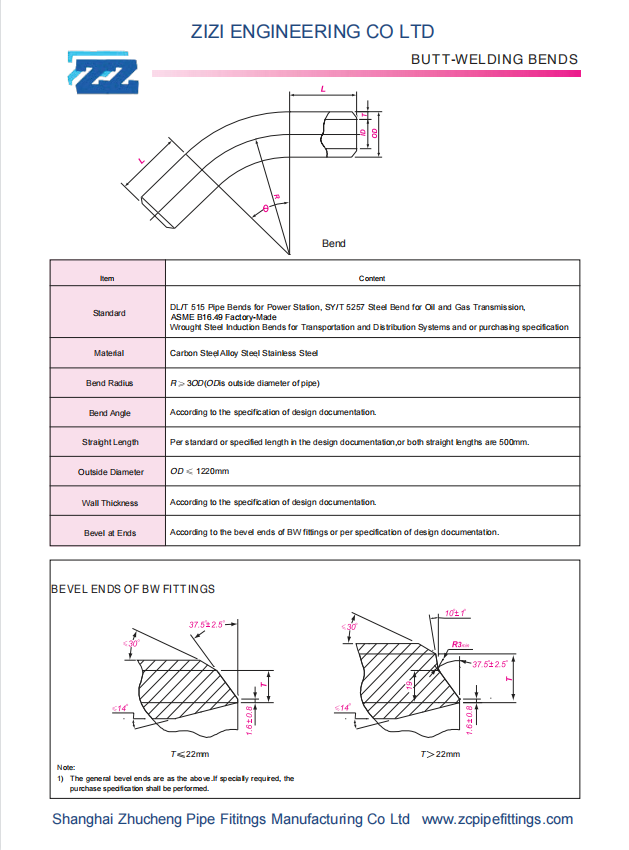

Specification of pipe bend

Type 90 Degree and 45 Degree

Size Range 1/2″ – 48″ / DN15 – 1200

Thickness Schedule SCH 10 – SCH 160, XXS

Bending Radius R≥3D (R= 3D, 4D, 5D, 6D, 7D, 8D, 9D, 10D)

Straight Length The length of both ends is generally 300-1500MM

China Standard GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409

America Standard ANSI / ASME B16.9 / MSS SP 43

Carbon Steel Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC, Galvanized

Low Temp Carbon Steel Q345B, 16Mn, ASTM A420 WPL6

Pipeline Steel ASTM A860 WPHY 42 / 46 / 56 / 60 / 65

Alloy Steel ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5

Stainless Steel ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L.

Difference between pipe bend and elow

The most basic difference of them is the elbow relatively short than bend, R = 1D to 2 D is elbow More than 2D is bend. In the production process, cold bends can use Bending Machine to bend by ready-made straight bend. One-time completed also don’t need second corrosion. But elbow need manufacturers make to order, to do anti-corrosion, order cycle is long. Elbow price is higher than bend. But cost performance is much higher than bend. It is well-known that bend do not have anticorrosive processing is easy damaged, but the price is cheap so are used very much in some demand which not very high engineering.