What is a Butt Welding Tee?

CompariTee welding joints are formed when two pieces intersect at a 90° angle. This results in the edges coming together in the center of a plate or component in a ‘T’ shape. Tee joints are considered to be a type of fillet weld, and they can also be formed when a tube or pipe is welded onto a base plate.

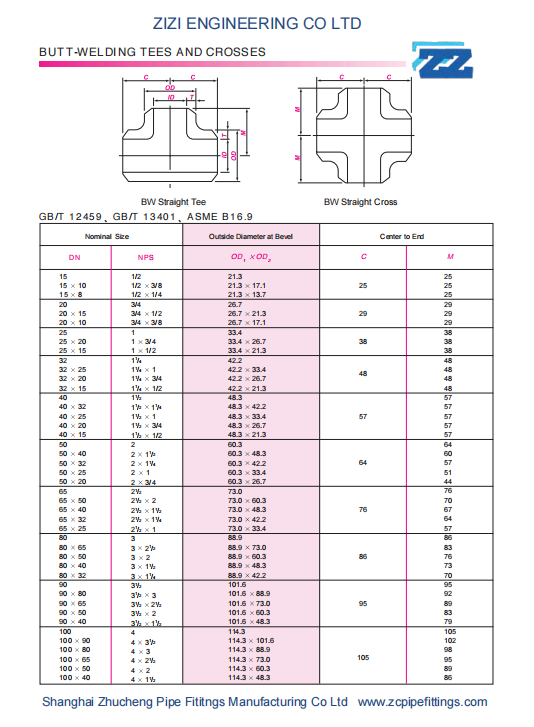

Specification of Butt Welding Tee

| Shape Type | Equal Tee and Reducing Tee |

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Germany Standard | DIN2605/2615/2616/2617 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

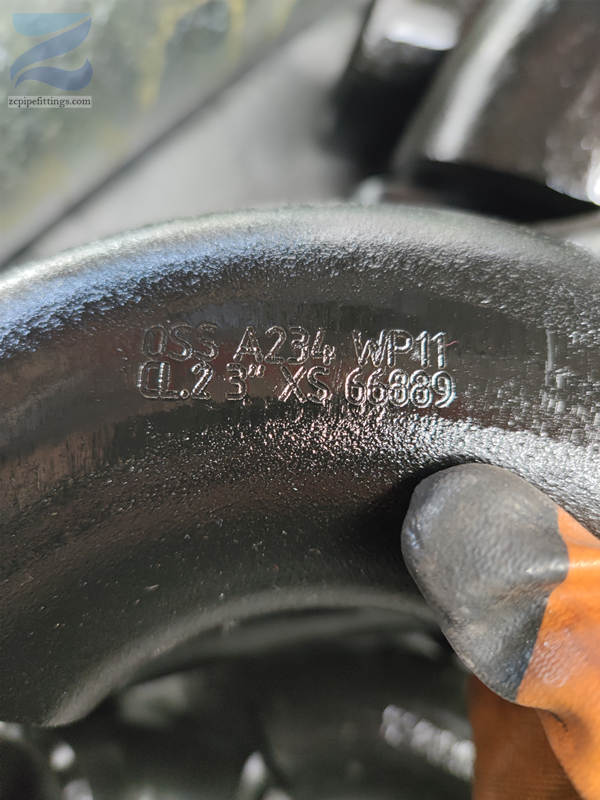

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

Advantages of Butt Welding Tee

Comparing to other types of steel pipe fittings,butt welding pipe fittings has advantages:

1.Butt welding joint is permanently leakproof and strong.

2.Continuous steel structure of the joints between the pipes and fittings have a good strength in the piping system.

3.The butt welding pipe fittings commonly have a smooth surface and gradual directional changes,it will decrease the pressure losses and turblence of the system,and protect from the corrosion and erosion.

4.The butt welding pipe fittings have a lower cost in bugdet.

5.The butt welding joints have a smaller space in the system.