Home » Buttwelding Fittings » ASTM A234 WPB BUTT WELDING PIPE FITTING CAP ASME B 16.9 MSS SP43

ASTM A234 WPB BUTT WELDING PIPE FITTING CAP ASME B 16.9 MSS SP43

What is a CAP nipple and what about its specification and advantages.

Contact US

Get Price

Share:

Content

What is a BW cap ?

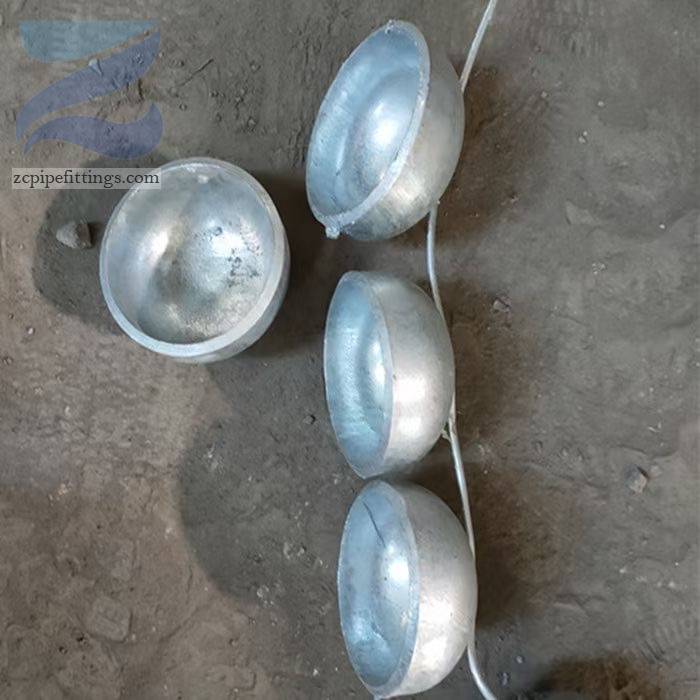

Basically a cap will be applied, to shut down the end of a pipe. The Cap, as it is shown in the image below, is available for all pipe dimensions, and is sometimes also used for other purposes.End Caps are used for blocking off or sealing the end of a pipeline. The end cap is welded on at its weld prep to the relevant sized pipe within the pipeline that requires blocking off/sealing. Once in place, unlike a blind flange that can be unbolted to allow access to the pipeline, the end cap is firmly fixed.

Specification of a BW cap

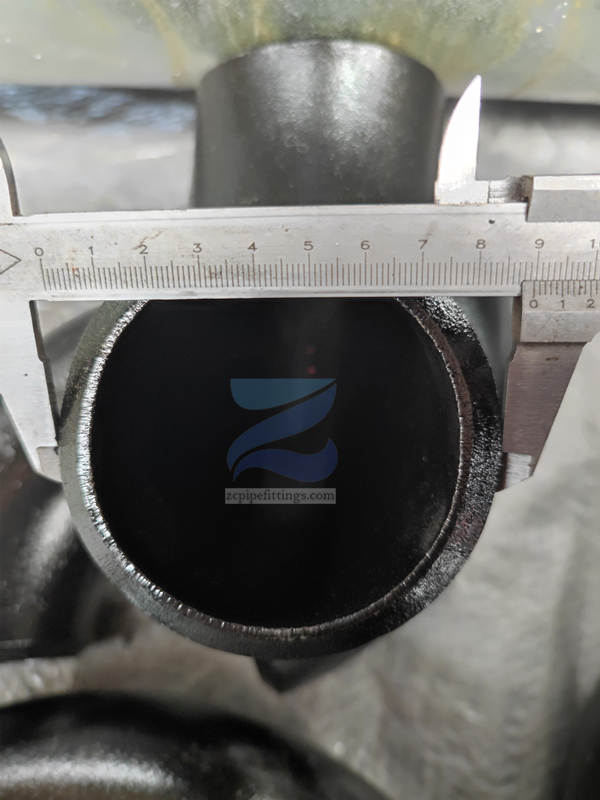

| Size Range | 1/2″-48″/DN15-DN1200 |

| Thickness Schedule | SCH10-SCH160,XSX |

| China Standard | GB/T12459,GB/T13401,HG/T21635/21631,SH348/3409 |

| America Standard | ANSI/ASME B 16.9/MSS SP43 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235,20#,35#,45#,20G,ASTM A234 WPB/WPC |

| Low Tem Carbon Steel | Q345B,16Mn,ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42/46/46/60/65 |

| Alloy Steel | ASTM A234 WP11/WP12/WP5/WP9/WP91/WP92,15CrMoG |

| Stinless Steel | ASTM A403 WP304/304L/304H,316,316L,310S,317,347,904L |

Advantages of BW caps

Butt welding capss have the following benefits

- allow strong, and leak-proof, piping connections

- minimize pressure drops and the turbulence inside the pipeline

- have a long service life

- are rather cheap to purchase and deploy

Inquiry

More Buttwelding Fittings