What is a pipe bend?

A pipe bend is the generic term for what is called in piping as an “offset” – a change in direction of the piping. A bend is usually meant to mean nothing more than that there is a “bend” – a change in direction of the piping (usually for some specific reason) – but it lacks specific, engineering definition as to direction and degree. Bends are usually custom-made (using a bending machine) on site and suited for a specific need.Pipe bends typically have a minimum bending radius of 1.5 times pipe radius (R). If this bending radius is less than 1.5R, it is called Elbow. Reference to any international / industry standard need to be traced. 1.5, 3 and 4.5 R are the most common bending radii in industry.

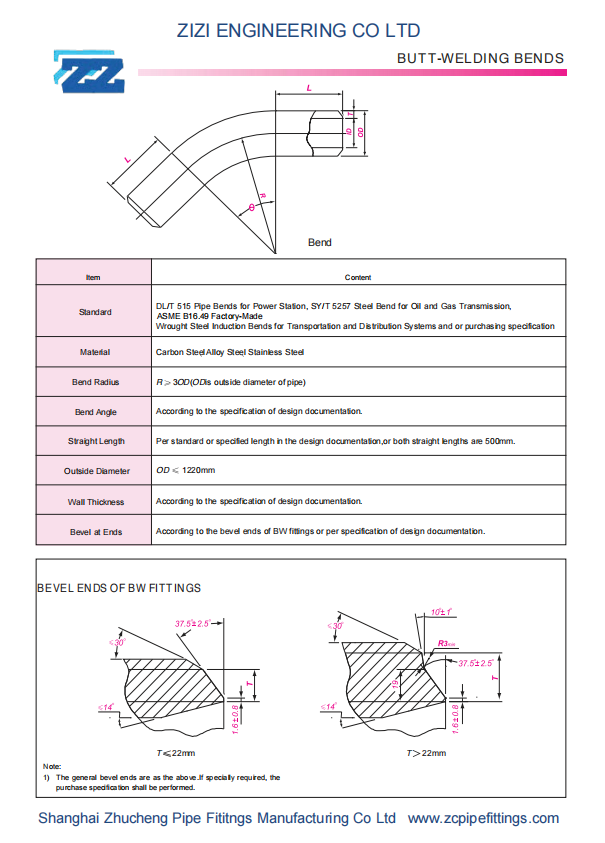

Steel piepe bends and elbows specification

| Shape type | 90Degree and 45Dgree |

| Size Range | 1/2″-48″/DN15-DN1200 |

| Thickness Schedule | SCH10-SCH160,XSX |

| Bending Radius | R≥3D(R=3D,4D,5D,6D,7D,8D,9D,10D |

| Straight Length | Generally 300-1500MM |

| China Standard | GB/T12459,GB/T13401,HG/T21635/21631,SH3408/3409 |

| America Standard | ANSI/ASME B 16.9/MSS SP43 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235,20#,35#,45#,20G,ASTM A234 WPB/WPC,Galvanized |

| Low Tem Carbon Steel | Q345B,16Mn,ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42/46/46/60/65 |

| Alloy Steel | ASTM A234 WP11/WP12/WP5/WP9/WP91/WP92,15CrMoG |

| Stinless Steel | ASTM A403 WP304/304L/304H,316,316L,310S,317,347,904L |

Difference between a pipe elbow and a pipe bend is as follows:

1.Pipe Bend is a generic term for any offset or change of direction in the piping. It is a vague term that also includes elbows.

2.An elbow is an engineering term and they are classified as 90 deg or 45 deg, short or long radius.

3.Pipe elbows have industrial standards and have limitations to size, bend radius and angle. The angles are usually 45 deg or 90 degrees. All others offsets are classified as pipe bends.

4.Bends are generally made or fabricated as per the need of the piping; however elbows are pre fabricated and standard, and are available off the shelf.

5.Bends are never sharp corners but elbows are. Pipe bending techniques have constraint as to how much material thinning can be allowed to safely contain the pressure of the fluid to be contained. As elbows are pre fabricated, cast or butt welded, they can be sharp like right angles and return elbows which are 180 degrees.

6.Elbow is a standard fitting but bends are custom fabricated.

7.In bends as the pipe is bent and there is no welding involved, there is less pipe friction and flow is smoother. In elbows, the welding can create some friction.

8.All elbows are bends but all bends are not elbows.

9.Bend has a larger radius then elbows.

10.Generally the most basic difference is the radius of curvature. Elbows generally have radius of curvature between one to twice the diameter of the pipe. Bends have a radius of curvature more than twice the diameter