ASTM A234 WPB Butt Weld Cap

ASTM A234 WPB butt weld cap is a pipe fitting end cap that is weldable, belongs to grade B and is pressure capable. The 234 stands for seamless steel standard for pipe fittings. A234 WPB Caps can be used in a variety of applications and industries. The A234 WPB Cap is used to secure an end line of a piping and seal it water tight.

ASTM A234 WPB butt weld cap is a pipe fitting end cap that is weldable, belongs to grade B and is pressure capable. The 234 stands for seamless steel standard for pipe fittings. A234 WPB Caps can be used in a variety of applications and industries. The A234 WPB Cap is used to secure an end line of a piping and seal it water tight. ASTM A234 WPB Cap might have a female threaded interior if it has to join to a threaded end of pipe.

A234 WPB Cap is used in water flow systems, water supply lines and in low pressure fluid flow systems. WPB End Cap can be seamless or welded.Depending on the chemical composition of the material used in the ASTM A234 butt weld cap, the maximum temperature for operation can differ. Although ASTM A234 Cap is used in low and high pressure systems, the low pressure applications are the most common.

Qualification of ASTM A234 WPB Cap

| Specification: | ASTM A234 WPB End Cap |

| Size: | 1/2” – 48” / DN15 – 1200 |

| Type: | Butt Weld (BW), Seamless (SMLS) Welded |

| Thickness: | SCH10 SCH20 STD SCH40 SCH60 SCH80 SCHXS SCH100 SCH120 SCH140 SCH160 SCHXXS |

| Standard | ASME B16.9 |

| Type Of Dimension: | BS1640, EN 10253 – 4, DIN 2605, JIS B2312, ANSI B16.9, MSS SP-75, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2313 |

| Carbon Steel | A234WPB/WPC |

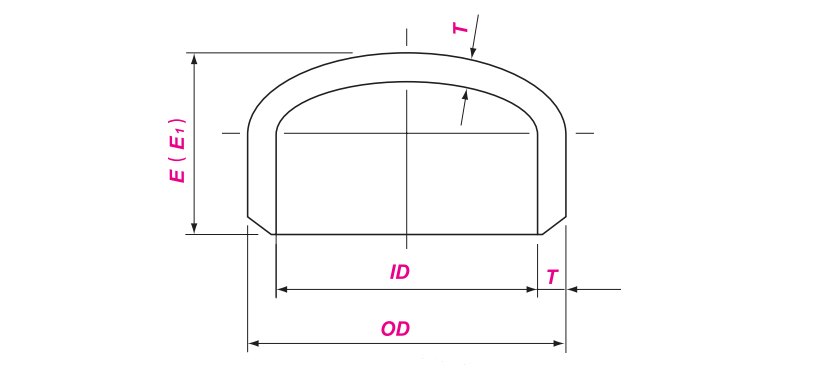

Butt Weld Cap Dimensions

| DN | NPS | OD | E | E1 |

|---|---|---|---|---|

| 15 | 1/2 | 21.3 | 25 | 25 |

| 20 | 3/4 | 26.7 | 25 | 25 |

| 25 | 1 | 33.4 | 38 | 38 |

| 32 | 1 1/4 | 42.2 | 38 | 38 |

| 40 | 1 1/2 | 48.3 | 38 | 38 |

| 50 | 2 | 60.3 | 38 | 44 |

| 65 | 2 1/2 | 73 | 38 | 51 |

| 80 | 3 | 88.9 | 51 | 64 |

| 90 | 3 1/2 | 101.6 | 64 | 76 |

| 100 | 4 | 114.3 | 64 | 76 |

| 125 | 5 | 141.3 | 76 | 89 |

| 150 | 6 | 168.3 | 89 | 102 |

| 200 | 8 | 219.1 | 102 | 127 |

| 250 | 10 | 273 | 127 | 152 |

| 300 | 12 | 323.9 | 152 | 178 |

| 350 | 14 | 355.6 | 165 | 191 |

| 400 | 16 | 406.4 | 178 | 203 |

| 450 | 18 | 457 | 203 | 229 |

| 500 | 20 | 508 | 229 | 254 |

| 550 | 22 | 558.8 | 254 | 254 |

| 600 | 24 | 609.6 | 267 | 305 |

| 650 | 26 | 660.4 | 267 | – |

| 700 | 28 | 711.2 | 267 | – |

| 750 | 30 | 762 | 267 | – |

| 800 | 32 | 812.8 | 267 | – |

| 850 | 34 | 863.6 | 267 | – |

| 900 | 36 | 914.4 | 267 | – |

| 950 | 38 | 965.2 | 305 | – |

| 1000 | 40 | 1016 | 305 | – |

| 1050 | 42 | 1066.8 | 305 | – |

| 1100 | 44 | 1117.8 | 343 | – |

| 1150 | 46 | 1168.4 | 343 | – |

| 1200 | 48 | 1219.2 | 343 |

Difference between Steel Pipe Caps and Plugs

- Connection

Steel pipe caps are used to connect with pipeline by welding and screwing. There is one way for plugs that screw on the ends of pipe.

- Shape

There are three shapes of steel pipe cap that butt weld cap, socket weld cap and threaded cap. While threaded plug have hex head, round head and square head.

- Standard

Manufacturing standard of pipe cap is ASME B16.9 & ASME B16.11 and plug is ASME B16.11

- Process

The manufacturing process for threaded plug is forging and casting. While for caps, it is hot press or cold press and forging.

- Thread

Threaded cap have female thread while plug is male thread.