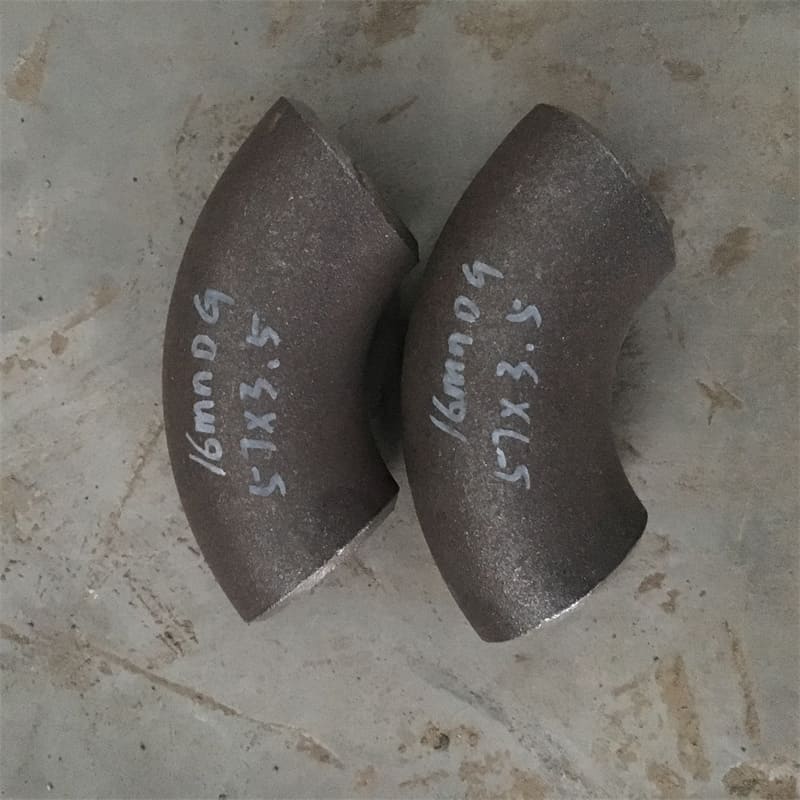

What is a 90 degree elbow?

The function of an elbow is to change direction of flow in a piping system. Elbows are split into three groups, which define the distance over which they change direction, which is expressed as a function of the distance from the centre line of one end to the opposite face. This is known as the centre to face distance and is equivalent to the radius through which is the elbow is bent. 90 degree elbow, also called “90 bends or 90 elbows”, are manufactured as SR (Short Radius) elbows andLR (Long Radius) elbows. SR (Short Radius) elbows have a Center-to-Face dimension of 1.0 X diameter and are typically used in tight areas where clearances are an issue.

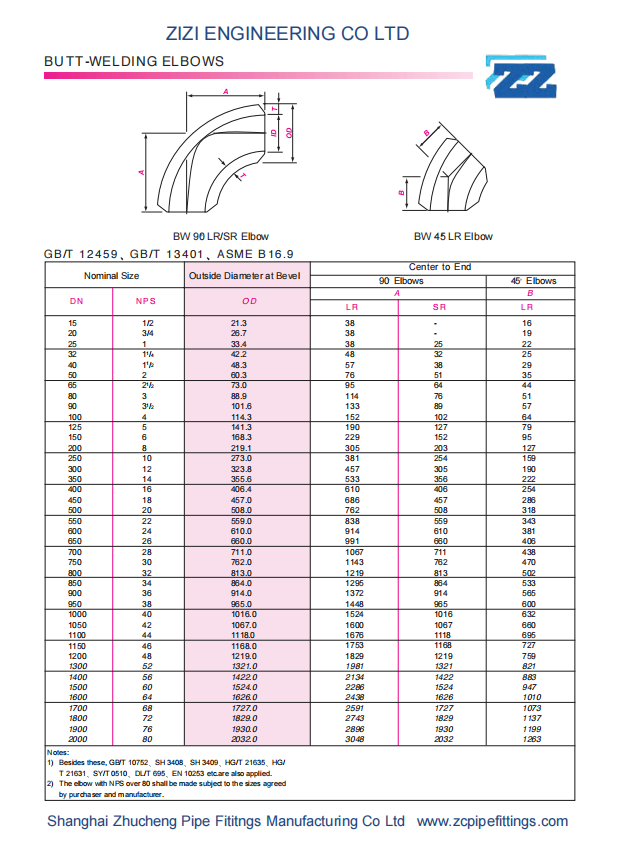

Dimensions of BW 90 degree elbow

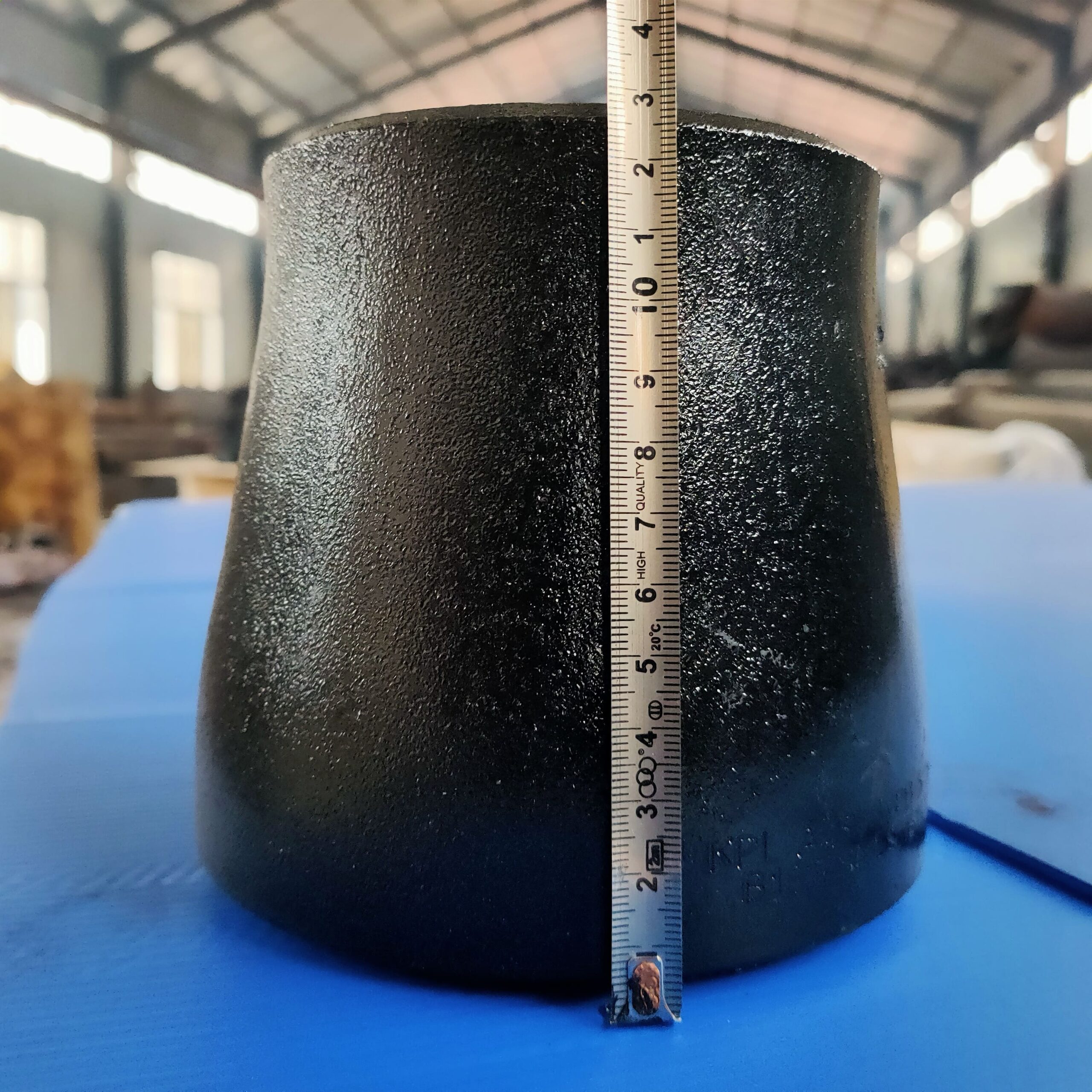

| Size Range | 1/2″ – 80″ / DN15 – 2000 |

| Thickness Schedule | SCH 10 – SCH 160, XXS |

| Bending Radius | Long Radius (LR) and Short Radius (SR) |

| China Standard | GB/T12459, GB/T13401, HG/T21635/21631, SH3408/3409 |

| America Standard | ANSI / ASME B16.9 / MSS SP 43 |

| Japan Standard | JIS B2311/2312/2313 |

| Europe Standard | EN10253 |

| Carbon Steel | Q235, 20#, 35#, 45#, 20G,ASTM A234 WPB/WPC |

| Low Temp Carbon Steel | Q345B, 16Mn, ASTM A420 WPL6 |

| Pipeline Steel | ASTM A860 WPHY 42 / 46 / 56 / 60 / 65 |

| Alloy Steel | ASTM A234 WP11 / WP12 / WP 5 / WP9 / WP91 / WP92,15CrMoG, 12Cr1MoVG, 12Cr5Mo, 1Cr5Mo, Cr9Mo, 10CrMo910, 12CrMo4-5 |

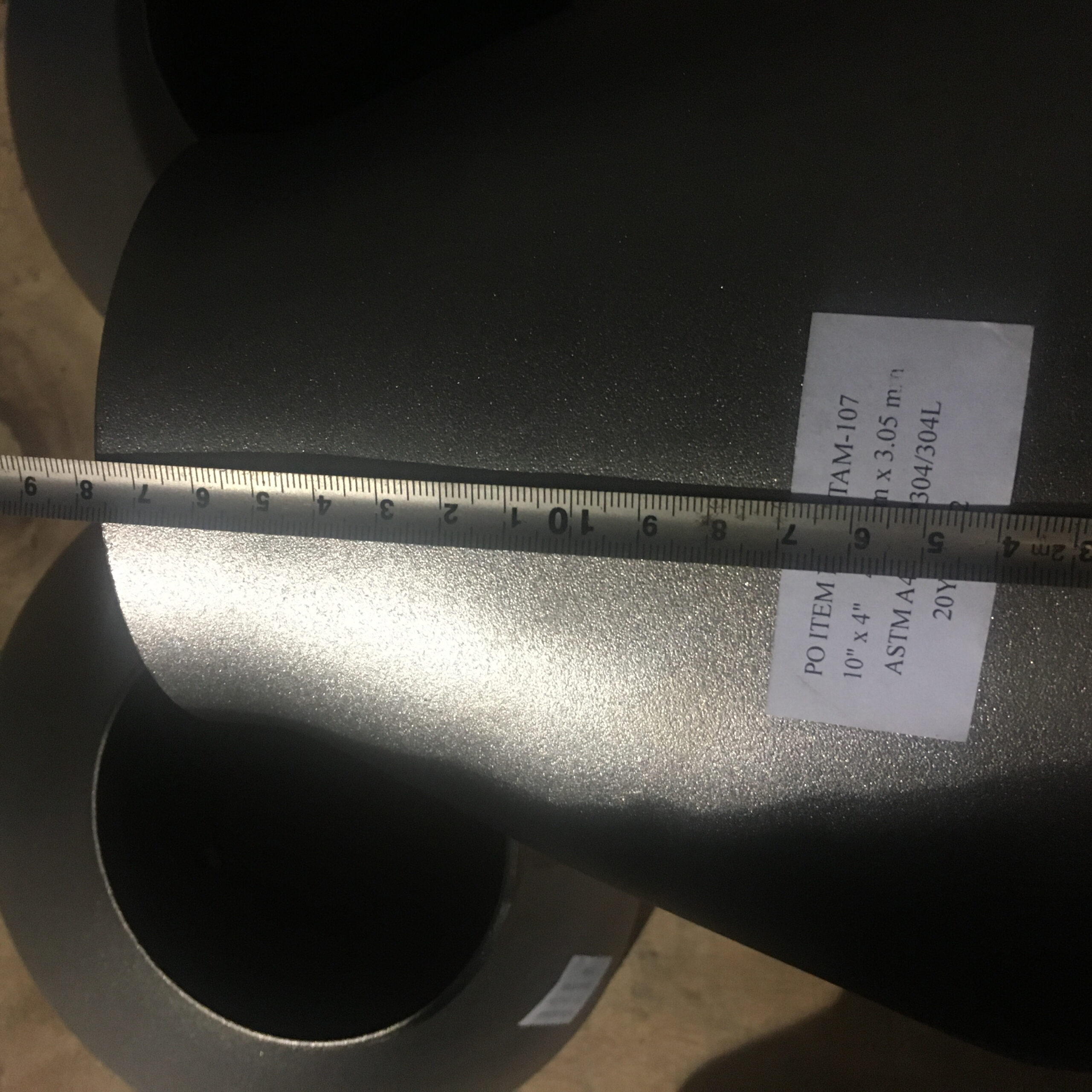

| Stainless Steel | ASTM A403 WP304/304L/304H, 316/316L, 310S, 317,347,904L |

Usage of elbows

In addition to the flex point for your arm, elbows are industrial fittings that change the direction of piping. The connections allow you to reroute regularly threaded pipes to turn corners or fit in limited space without the expense of buying a pipe bender.