ASTM A182F 316L Forged Steel Thread Flange

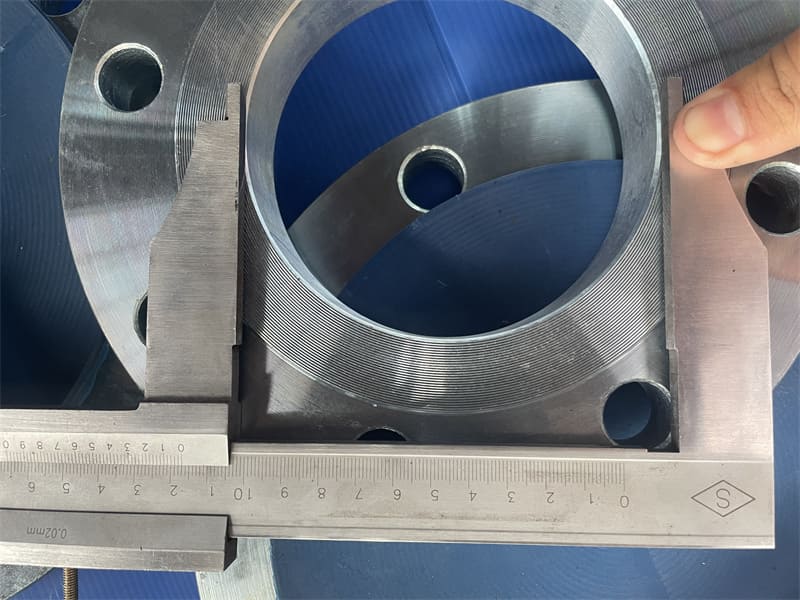

Threaded Flanges are also known as screwed flange, and it is having a thread inside the flange bore which fits on the pipe with matching male thread on the pipe.

He most popular threaded flanges range in ½ inch to 6” nominal pipe size, but we are able to offer NPT threaded flanges up to 24” if necessary. The amount of additional machining and labor hours which go into producing a larger diameter threaded connection make them less popular than a slip on or weld neck configuration. It may be of significantly beneficial use for an application which requires connecting and disconnecting from time to time. The male pipe end is joined to the flange without a weld connection required but can be sealed with a weld if necessary. This weld seal would defeat the purpose of a threaded flange as a structural option, as its primary advantage is to assemble and disassemble the connection. For the purposes of pressure vessel equipment, the weld seal can be applied if the user is certain they would like to keep the pipe and flange assembly sealed permanently. Threaded flange connections are often a requirement when a male NPT pipe connection is utilized and the media in question is highly reactive or explosive in nature, which is why NPT/threaded companion flanges are commonly utilized in API oilfield service. This API 6A specification also allows for a male thread flange connection, but this is much less common than

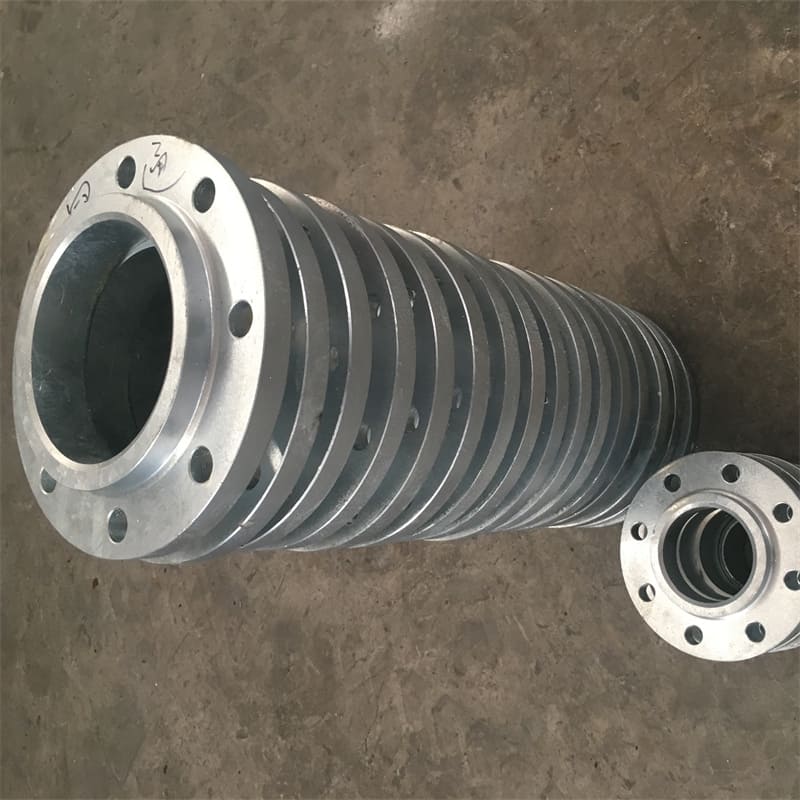

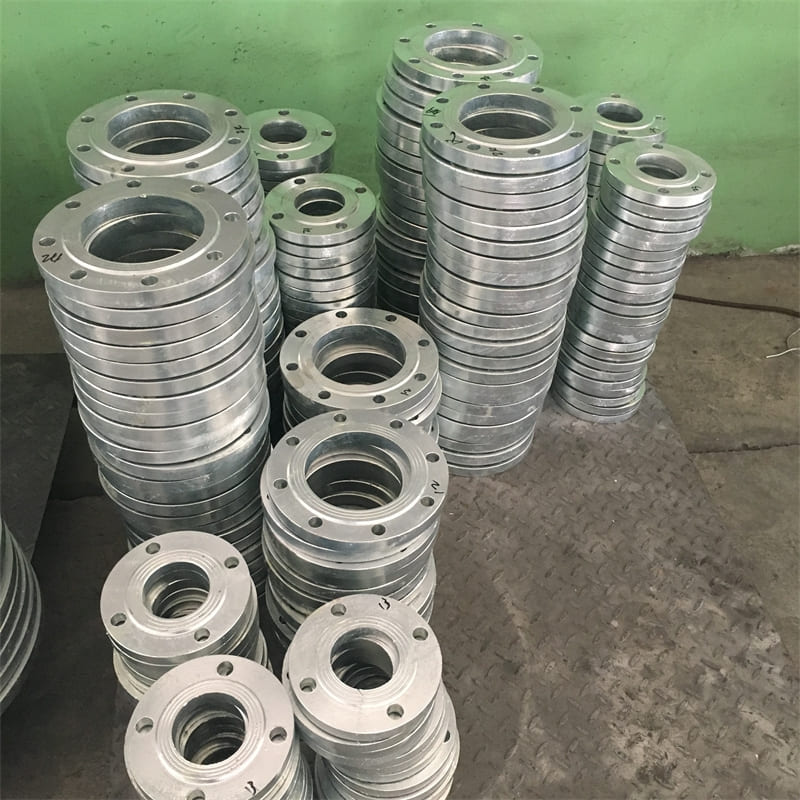

| Shape | Weld Neck Flange ( WN),Slip-on Flange (SO), Threaded Flange (THD),Socket Weld Flange (SW),Blind Flange (BL),Lap Joint Flange (LAPJ),Plate flange (PL) |

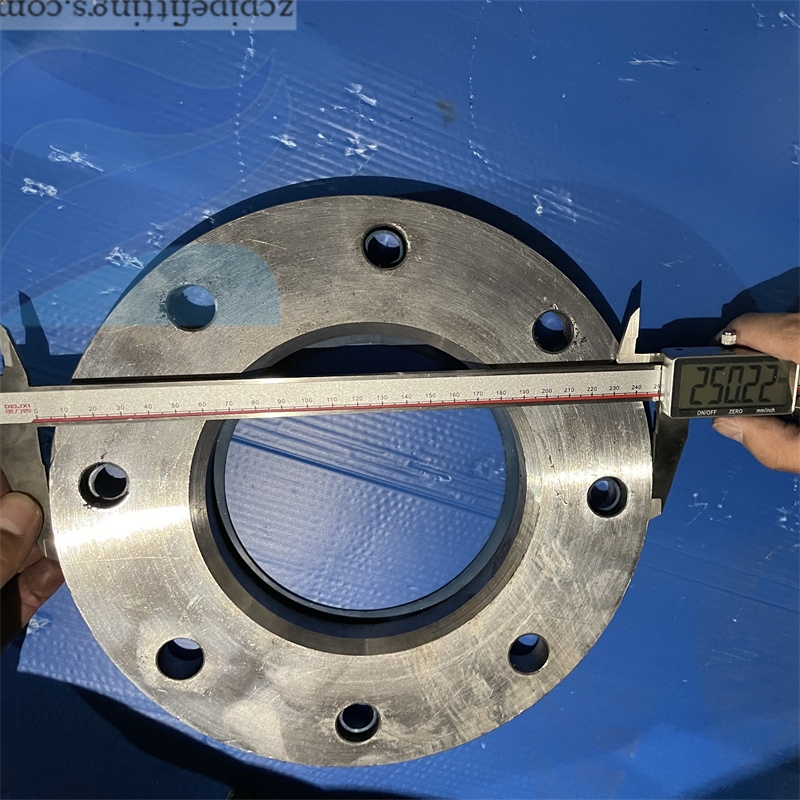

| Size Range | 1/2″ – 48″/ DN15 – DN1200 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

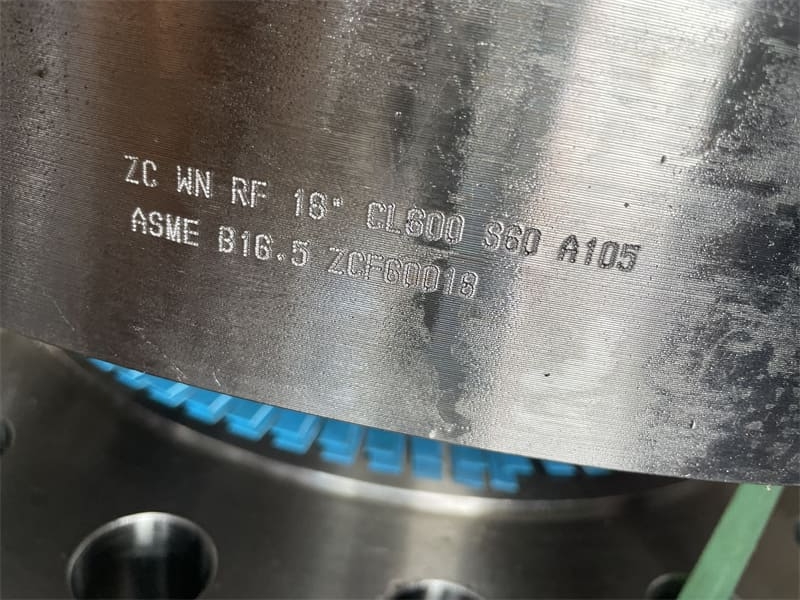

| Standard | ASME B16.5, ASME B16.47 Series A/B, EN 1092-1, API 605, MSS SP-44, DIN 2627, DIN 2527, DIN 2558, DIN 2576, DIN 2641, DIN 2655, DIN 2656, DIN2573 |

| Carbon Steel | ASTM A105 / A105N, ASTM A350 LF2/LF3, ASTM A694 F42 / 46 / 56 / 60 / 65, P235GH, P265GH, P280GH, P355GH |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 321, 310S, 317,347,904L, 1.4404, 1.4437. |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

The various types of threaded flanges are as follows:

Plain Threaded Flanges

Female Threaded Flanges

Male Threaded Flanges

Uses of threaded flanges :

Threaded flanges are threaded in the bore which match an external thread on the pipe. Threaded flanges are used with pipes that have external threads. The benefit of these flanges is that it can be attached without welding.

Threaded flanges can be fitted to pipes of various sizes without welding and this is one chief benefit for which these flanges are highly demanded.

They can be used in extremely high pressure applications, particularly at or near atmospheric temperature, where the necessary post weld heat treatment is not possible.

They are ideal for small diameter piping applications.

They are economical and time saving devices.

These threaded flanges are normally designed for non-cyclic applications.

The flanges are suitable to be used in applications where welding is hazardous.

They can be used in highly explosive areas.

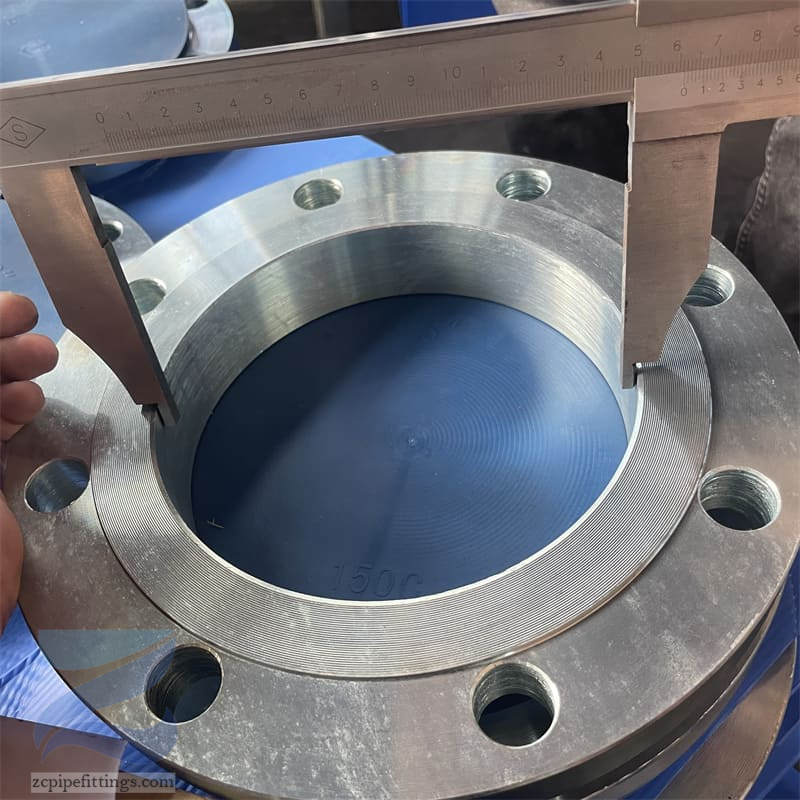

Details of Threaded flange

They are the special type of pipe flanges which can be attached to the pipe without welding.

Threaded flanges are often used for small diameter, high pressure requirements. thread flanges with a hub have published specifications that range from 1/2″ thru 24″.

Class 150 lb Threaded Flange Dimensions & Weight

Notes

1) The thread conforms to ASME B1.20. 1 NTP threads as described in Section 10. (The only exceptions are small male and female plain face threaded flanges which use NPSL recount threads.)

2) Class 150 threaded flanges are made without a counterbore. Threads are chamfered to the major diameter (approx.) at an angle of 45° (approx.) at the back of the flange .

3) Weights are based on manufacturer’s data and are approximate.

4) If you need class 300 ,600 ,900 ,1500 ,2500 flanges,please contact us.