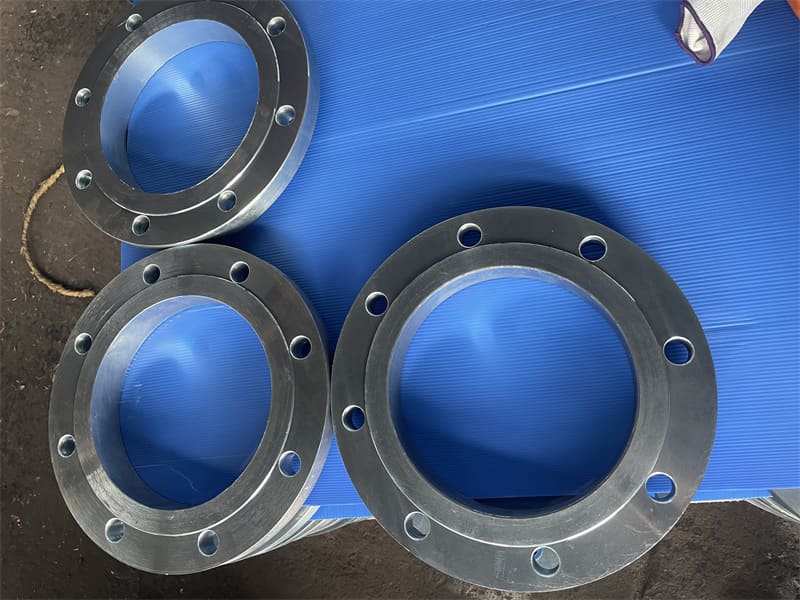

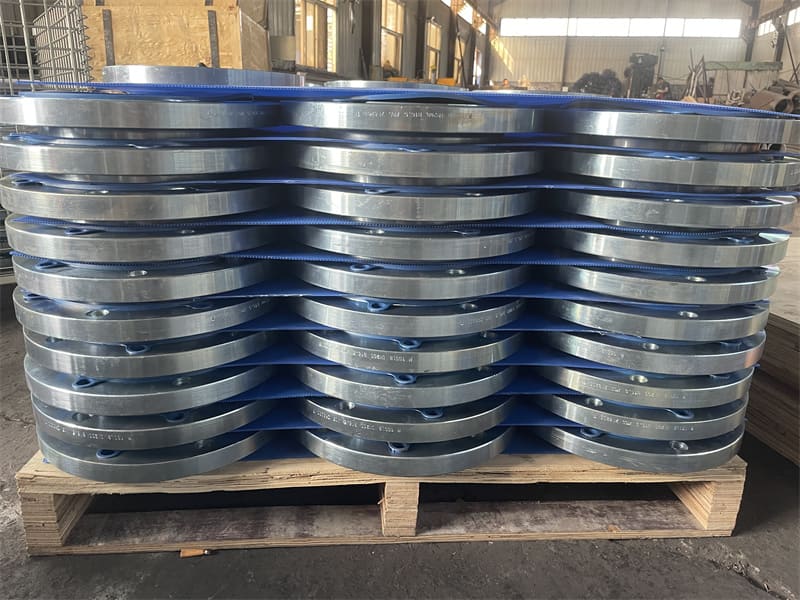

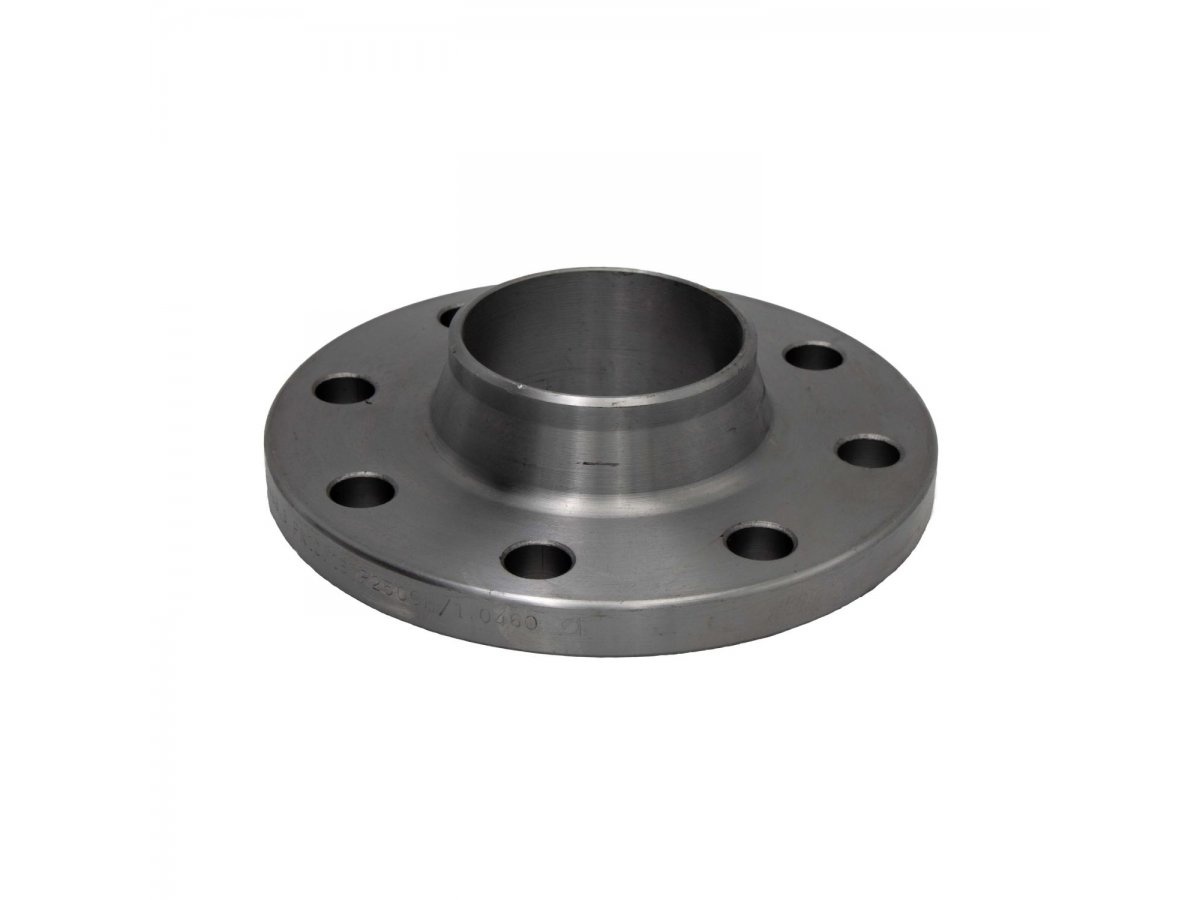

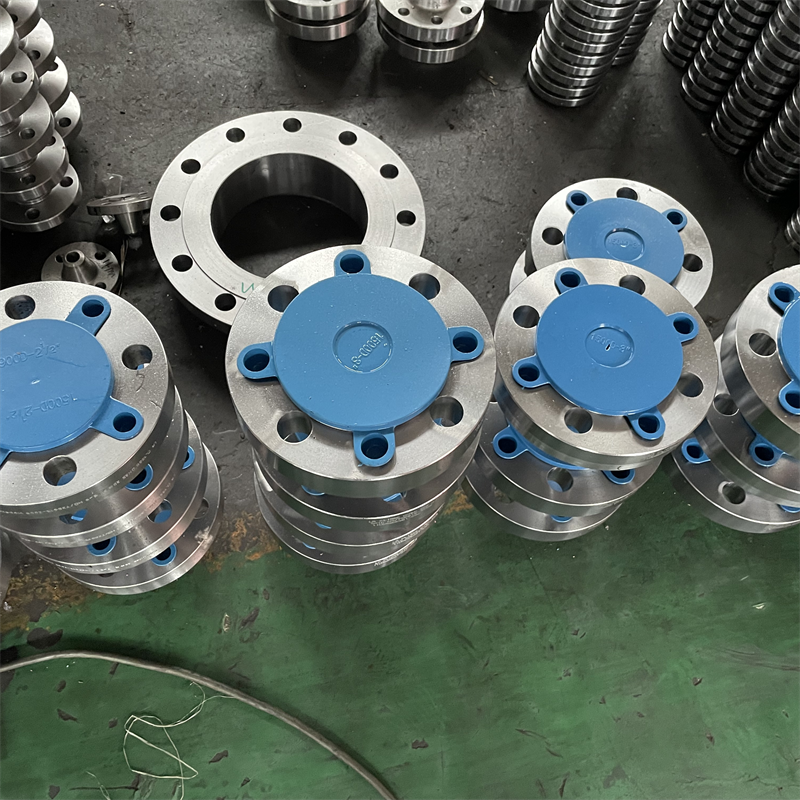

ASTM A182 Stainless Steel Flange

ASTM A182 Stainless Steel Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification.

ASTM A182 Stainless Steel Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification.

ASTM A182 is a standard specification developed by ASTM International (formerly known as the American Society for Testing and Materials) that covers a variety of forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves Components for high-temperature service. Within this specification, there are various grades of materials specified, including stainless steel grades.

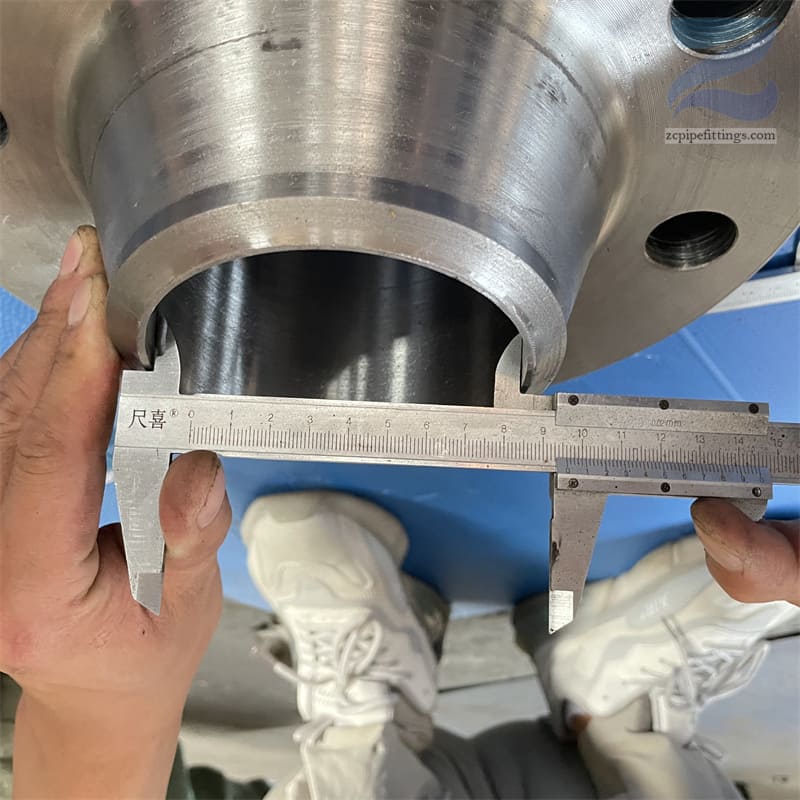

Specification of ASTM A182 Flange

| Sealing Face | RF, FF, FTJ |

| Size Range | 1/2″ – 24″ / DN15 – DN600 |

| Pressure Rating | Class 150, 300, 600, 900, 1500, 2500lb |

| Standard | ANSI / ASME B16.5, EN1092-1 |

| ASTM A182 Flange Types | Welding Neck Flange, Slip On Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Blind Flange, |

| Alloy Steel | ASTM A182 F11 / 12 / 5 / 9 / 91 / 92 |

| Stainless Steel | ASTM A182 F304/304L/304H, 316/316L, 310S, 317,347,904L |

| Duplex Stainless Steel | ASTM A182 F51, F53, F44 |

Material Grades of Stainless Steel Flange

ASTM A182 includes various stainless steel grades, such as 304,316,316L, 310S,347,904L and others。

A182 Stainless Steel Flanges Chemical Compostion

| CHEMICAL | LIMITS | C | Mn | P | S | Si | Ni | Cr | Mo | N |

|

ASTM A182 F304 |

MIN | 8 | 18 | |||||||

| MAX | 0.08 | 2 | 0.045 | 0.03 | 1 | 11 | 20 | 0.1 | ||

| ASTM A182 F316 | MIN | 10 | 16 | 2 | ||||||

| MAX | 0.08 | 2 | 0.045 | 0.03 | 1 | 14 | 18 | 3 | 0.01 | |

| ASTM A182 F317 | MIN | 11 | 18 | 3 | ||||||

| MAX | 0.08 | 2 | 0.05 | 0.03 | 1 | 15 | 20 | 4 | ||

| ASTM A182 F347 | MIN | 9 | 17 | |||||||

| MAX | 0.08 | 2 | 0.045 | 0.03 | 1 | 13 | 20 | |||

| ASTM A182 F904L (N08904) | MIN | 23 | 19 | 4 | ||||||

| MAX | 0.02 | 2 | 0.04 | 0.03 | 1 | 28 | 23 | 5 | 0.1 | |

| ASTM A182 F51 | MIN | 4.5 | 21 | 2.5 | 0.08 | |||||

| MAX | 0.03 | 2 | 0.03 | 0.02 | 1 | 6.5 | 23 | 3.5 | 0.2 | |

| ASTM A182 F53 | MIN | 6 | 24 | 3 | 0.24 | |||||

| MAX | 0.03 | 1.2 | 0.035 | 0.02 | 0.8 | 8 | 26 | 5 | 0.32 | |

| ASTM F55 | MIN | 6 | 24 | 3 | 0.2 | |||||

| MAX | 0.03 | 1 | 0.03 | 0.01 | 1 | 8 | 26 | 4 | 0.3 |

A182 Stainless Steel Flanges Mechanical Property

| MATERIAL | ASTM A182 F304 | ASTM A182 F316 | ASTM A182 F317 | ASTM A182 F347 | ASTM A182 F904L | ASTM A182 F51 | ASTM A182 F53 | ASTM A182 F55 |

| T.S (MPA) | 515 min | 515 min | 515 min | 515 min | 490 min | 620 min | 800 min | 750-895 |

| Y.S (MPA) | 205 min | 205 min | 205 min | 205 min | 215 min | 450 min | 550 min | 550min |

| EL % | 30 min | 30 min | 30 min | 30 min | 35 min | 25 min | 25 min | 25min |

| R/A % | 50 min | 50 min | 50 min | 50 min | 45 min | 15 min | 45min |

Advantages of Stainless Steel Flange

Chemical corrosion resistance

High strength

Good toughness

Good welding performance